A kind of water-in-water pickering emulsion and preparation method thereof

A water-in-water emulsion technology, which is applied in the field of water-in-water emulsion preparation, can solve the problems of complicated equipment, difficult preparation of water-in-water emulsion, and inability to prepare stable water-in-water emulsion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

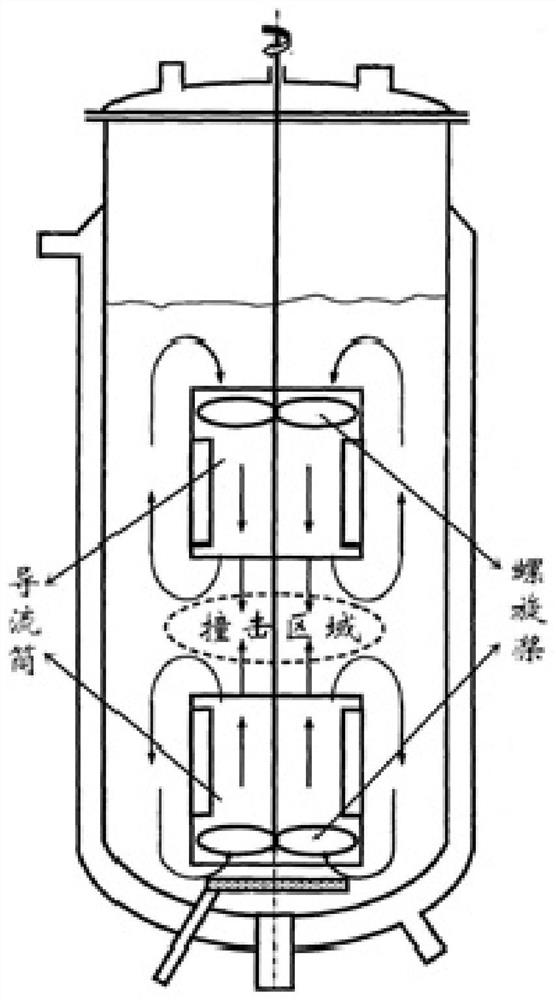

[0047] The present invention aims at the technical problem of difficult preparation of water-in-water emulsion in the prior art, especially for two incompatible water phases, i.e. water phase continuous phase and water phase dispersed phase, proposes a brand new emulsification method, this The method is capable of obtaining a stable water-in-water emulsion. The preparation method of the water-in-water Pickering emulsion proposed by the present invention, the water-in-water Pickering emulsion is obtained by mixing the water-phase continuous phase, the water-phase dispersed phase and the particle stabilizer, and then emulsifying by impinging flow, the water-phase continuous phase and the water phase The dispersed phase is an aqueous solution of a water-soluble polymer, and the continuous phase of the water phase and the dispersion of the water phase are immiscible with each other; the preparation method comprises the following steps:

[0048] The water-phase continuous phase dis...

Embodiment 1

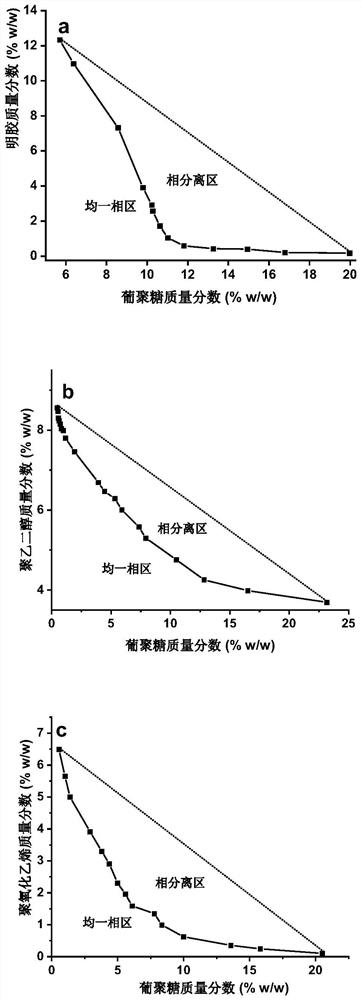

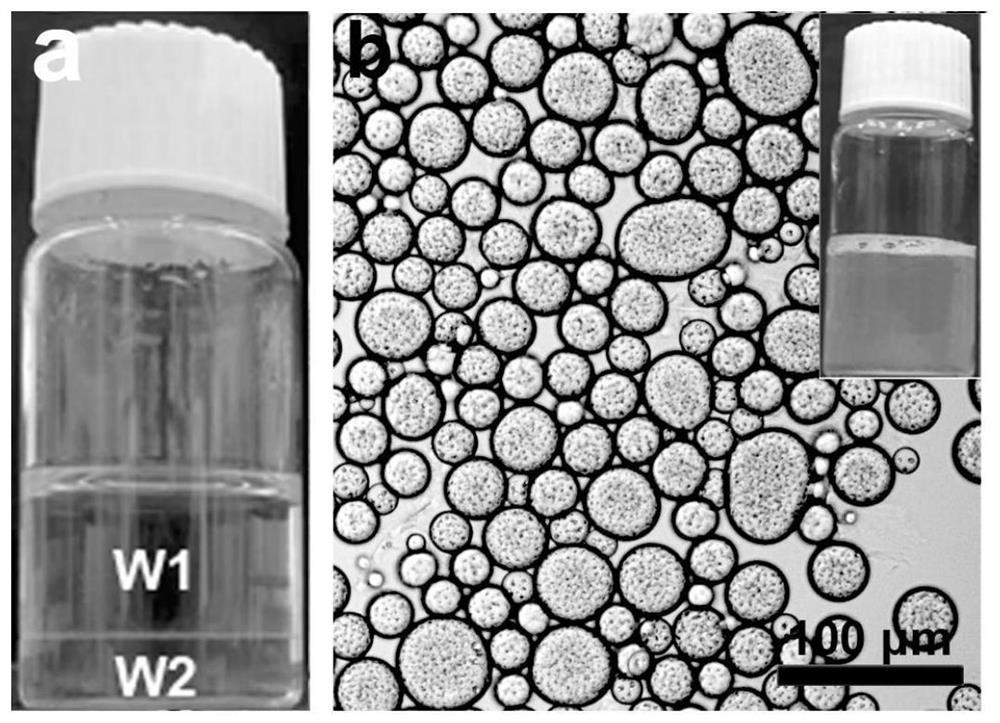

[0075] Preparation mass fraction is respectively 5% polyethylene glycol aqueous solution A (molecular weight is 88000Da, solubility parameter is 9.38 (Cal / cm 3 ) 0.5 ) and 5% dextran aqueous solution B (its molecular weight is 500000Da, solubility parameter is 23.1 (Cal / cm 3 ) 0.5 ), then respectively get 10 milliliters (volume ratio 1:1) of the above-mentioned solution and mix, after standing, make it phase separation. Take the upper phase and the lower phase in two containers respectively, wherein the liquid with less volume is used as the dispersed phase, and the liquid with more volume is used as the continuous phase. The continuous phase is placed in the impingement flow device, and the mass fraction of 0.01% cellulose solid particles is added to disperse in the continuous phase, and the water phase continuous phase dispersed with the particle stabilizer forms two strands through the diversion of the internal components of the impingement flow device. For the fluids co...

Embodiment 2

[0077] Preparation mass fraction is respectively 10% polyethylene glycol aqueous solution A (molecular weight is 88000Da, solubility parameter is 9.38 (Cal / cm 3 ) 0.5 ) and 10% dextran aqueous solution B (its molecular weight is 500000Da, solubility parameter is 23.1 (Cal / cm 3 ) 0.5), get 10 milliliters of polyethylene glycol aqueous solution and the above-mentioned solution of 50 milliliters polydextran aqueous solution (volume ratio 1:5) and mix, after standing, make it phase separation. Take the upper phase and the lower phase in two containers respectively, wherein the liquid with less volume is used as the dispersed phase, and the liquid with more volume is used as the continuous phase. The continuous phase is placed in the impinging flow device, and the mass fraction of 0.70% cellulose solid particles is added to disperse in the continuous phase, and the water phase continuous phase dispersed with the particle stabilizer forms two strands through the diversion of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com