A continuous purification device and process for organosilicon-containing copper contacts

A purification device and purification process technology, applied in the direction of silicon compounds, inorganic chemistry, process efficiency improvement, etc., can solve problems such as the inability to meet continuous production, and achieve the effects of reducing pressure, reducing operating costs, and realizing process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

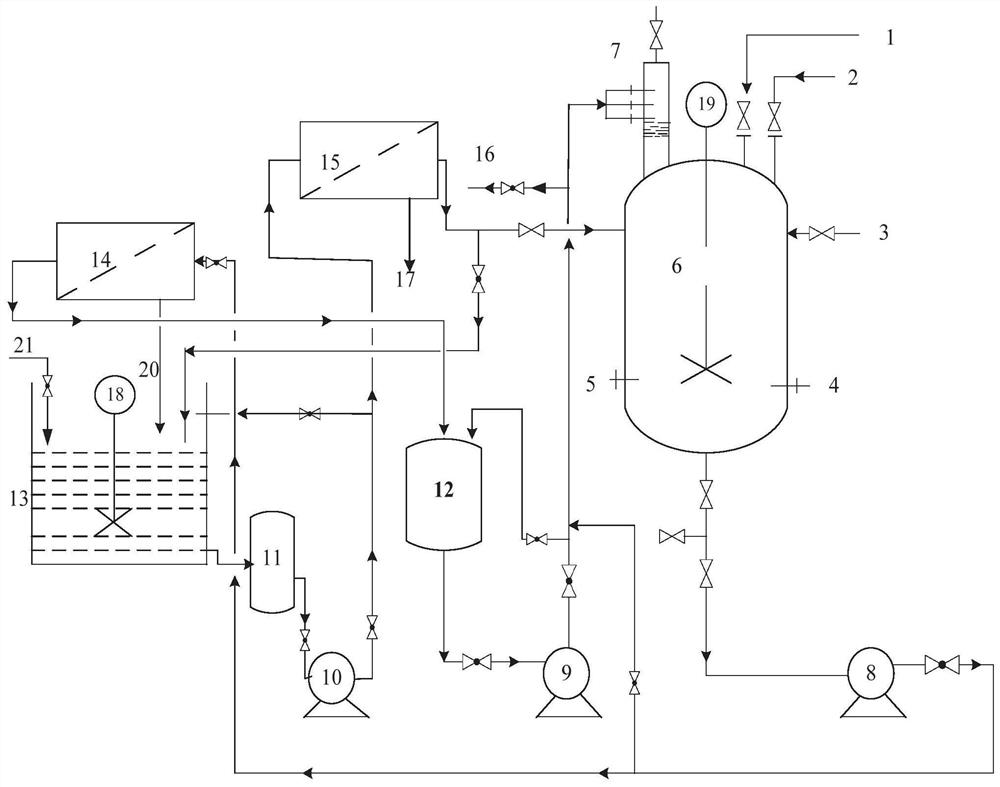

[0056] Such as figure 1 As shown, the present embodiment provides a continuous purification device for organosilicon-containing copper contacts, including a reaction tank 6, a first circulation pump 8 at the outlet of the reaction tank 6, and the pipeline behind the first circulation pump 8 is divided into two paths, so that the preliminary The filter unit and the secondary filter unit are connected in parallel;

[0057] The reaction tank 6 oxidizes the solid copper in the organosilicon copper-containing contact into an ion state;

[0058] The preliminary filtration unit includes a second circulation pump 9 and a filtrate tank 12 connected in sequence with the first circulation pump 8; the second circulation pump 9 and the filtrate tank 12 are connected in circulation pipelines, and the liquid in the filtrate tank 12 Pass into reaction tank 6;

[0059] The secondary filtration unit includes a first solid-liquid separation device 14, a washing and stirring tank 13, a third ci...

Embodiment 2

[0073] This embodiment provides a continuous purification process for organosilicon-copper-containing contacts, which is carried out in the continuous purification device for organosilicon-copper-containing contacts described in Example 1, including the following steps:

[0074] Hydrolysis reaction of waste contact body: transport 5 tons of waste contact body to reaction tank 6 through pipelines, control a certain temperature at 30°C-60°C, mix and react uniformly by stirring for 3-10 hours, use hydrochloric acid to control weak acid pH: 3-5 , adding an oxidizing agent such as hydrogen peroxide, nitric acid, or ozone to carry out an oxidation deactivation reaction.

[0075] The solution is divided into two paths after passing through the first circulation pump. The third circulation pump is turned on first, and the second circulation pump is turned on after the pressure of the third circulation pump is stable, and the solution enters the primary filtration unit and the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com