A carbonization test method with adjustable carbon dioxide concentration

A carbon dioxide and carbonization test technology, applied in various fluid ratio control, instruments, measuring devices, etc., can solve the problems of low gas pressure, limited carbonization effect research, and unadjustable pressure, so as to promote the increase of strength and adjust the method Simple and easy to implement, avoiding the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

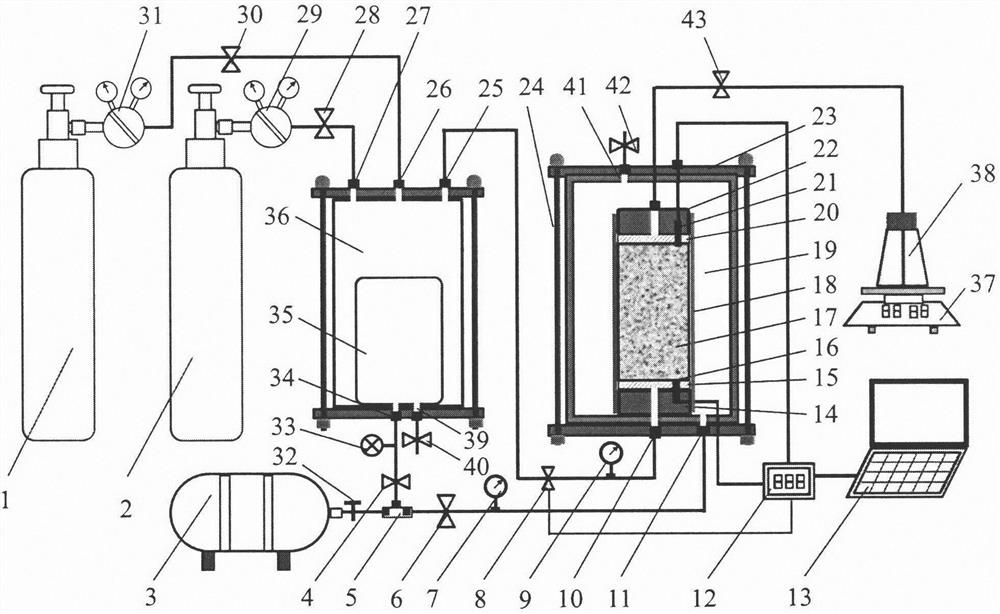

Image

Examples

Embodiment 1

[0035] If the sample is a cylinder with a diameter of 50mm and a height of 100mm, and the natural density of the sample soil is 1.8g / cm 3 , the initial water content is 20%, the alkaline material is 100% active magnesium oxide, and its dosage is 10%. Assuming that the sample undergoes a complete carbonization reaction, and its product is magnesium carbonate trihydrate, then according to the ideal gas state equation and the pressure P1, it can be determined that P1 is about 217kPa by twice the amount of carbon dioxide required for the sample to be completely carbonized. If the high-pressure gas introduced is nitrogen, and the carbon dioxide concentration is 70%, then P2 is about 310kPa.

Embodiment 2

[0037] If the sample is a cylinder with a diameter of 50mm and a height of 100mm, and the density of the sample contaminated soil is 1.85g / cm 3 , the initial water content is 20%, the alkaline material is 100% active magnesium oxide, and its dosage is 10%. Assuming that the sample has undergone a complete carbonization reaction, and its product is magnesium carbonate trihydrate, then according to the ideal gas state equation and the pressure P1, it can be determined that P1 is about 218kPa as twice the amount of carbon dioxide required for the sample to be completely carbonized. If the high-pressure gas introduced is nitrogen, and the carbon dioxide concentration is 70%, then P2 is about 312kPa.

Embodiment 3

[0039] If the sample is a cylinder with a diameter of 50mm and a height of 100mm, and the density of the sample contaminated soil is 1.8g / cm 3 , the initial water content is 25%, the alkaline curing agent is composed of 60% active magnesium oxide and 40% quicklime, and its dosage is 10%. Assuming that the sample undergoes a complete carbonization reaction, and its products are magnesium carbonate trihydrate and calcium carbonate, according to the ideal gas state equation and the pressure P1, it can be determined that P1 is about 218kPa according to twice the amount of carbon dioxide required for the sample to be completely carbonized. , if the selected high-pressure gas is helium, and the carbon dioxide concentration is 70%, then P2 is about 311kPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com