High-energy-density deformable batteries

An energy storage unit, energy storage device technology, applied in the direction of batteries, lithium batteries, battery electrodes, etc., can solve problems such as unsatisfactory energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

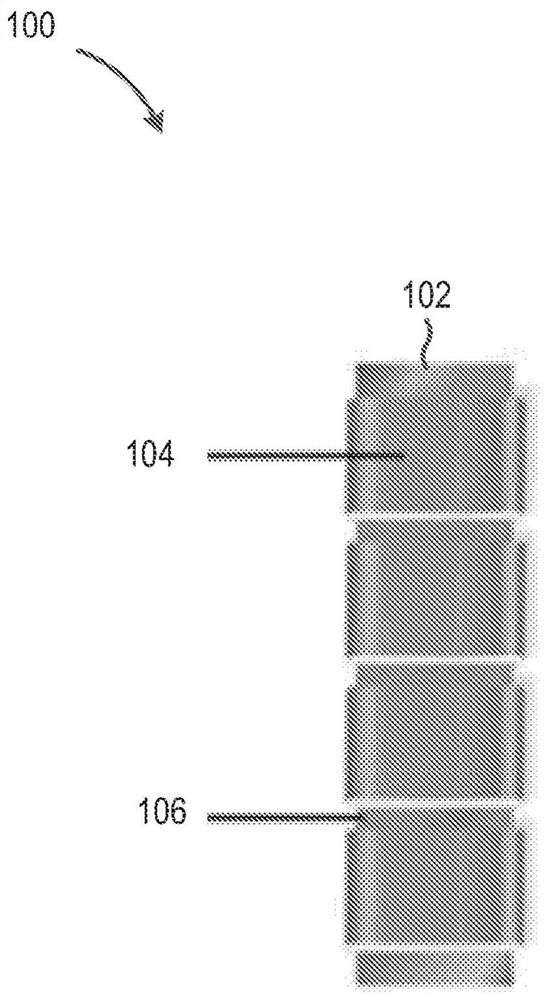

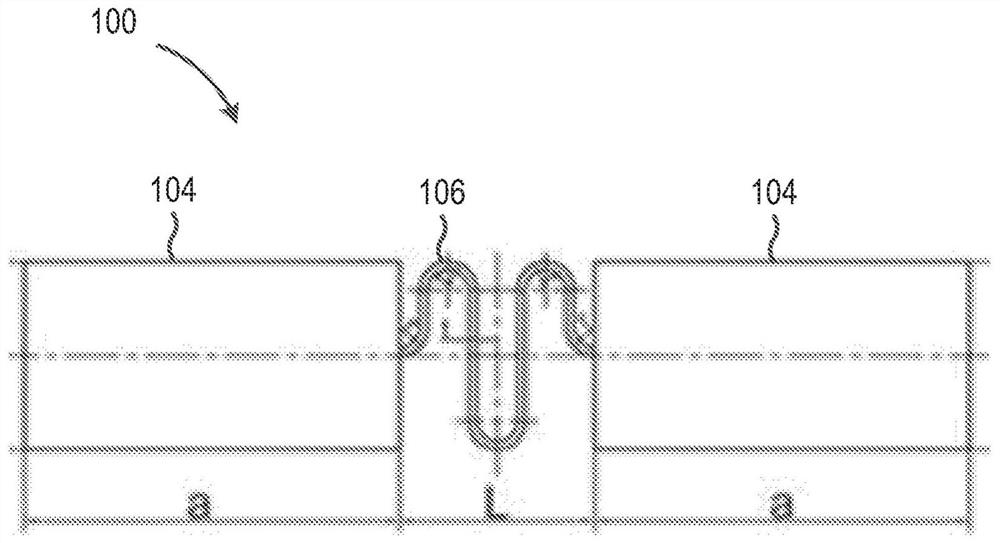

[0026] now refer to Figure 1A , some aspects of the disclosed subject matter include an energy storage device 100 having an axial structure 102 . In some embodiments, energy storage device 100 includes two or more rigid energy storage cells 104 arranged along axial structure 102 . In some embodiments, energy storage device 100 includes a plurality of energy storage units 104 . In some embodiments, a conductive flexible member 106 separates adjacent rigid energy storage units 104 . now refer to Figure 1B , in some embodiments, the energy storage device 100 is configured such that L / a is between 0.30 and 1.0, where L is the length of the conductive flexible member 106, and a is the rigid energy storage unit 104 adjacent to the conductive flexible member energy storage length.

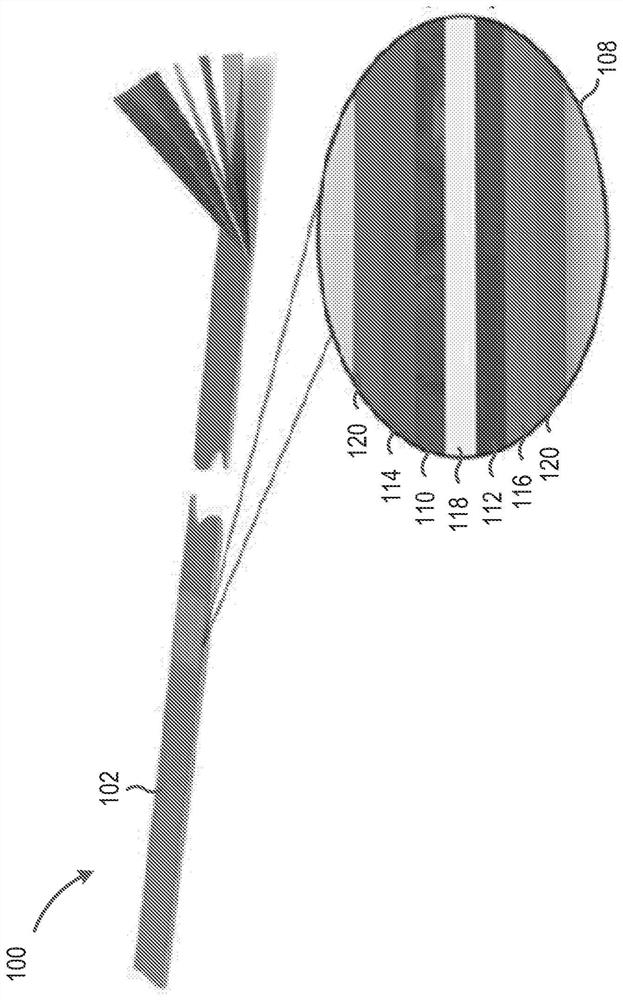

[0027] now refer to Figure 1C , in some embodiments, the axial structure 102 includes a plurality of layers 108 . In some embodiments, the plurality of layers includes an anode layer 110, a cathod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com