Antibacterial nano-microemulsion system, preparation method, application and application method

A nano-microemulsion and system technology, which is applied in the field of daily chemical industry, can solve problems that have not yet been discovered, and achieve the effects of easy operation, reducing irritation, and regulating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

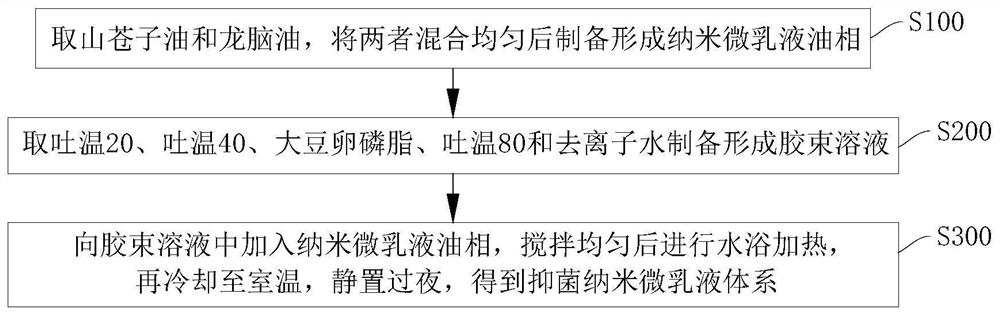

[0049]Seefigure 1 , The preparation method of the antibacterial nano microemulsion system includes the following steps:

[0050]S100) Take Litsea cubeba oil and borneol oil in the above-mentioned mass percentages, and mix them evenly to prepare a nano-microemulsion oil phase;

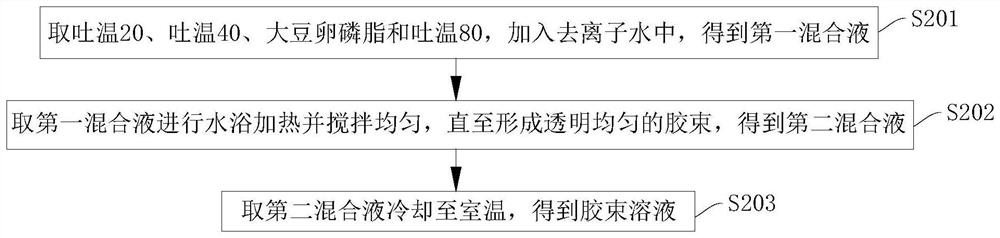

[0051]S200) Take Tween 20, Tween 40, soybean lecithin, Tween 80 and deionized water in the above mass percentage to prepare a micellar solution. For details, please refer tofigure 2 , The micellar solution is prepared by the following steps:

[0052]S201) Take Tween 20, Tween 40, soybean lecithin and Tween 80 and add them to deionized water to obtain a first mixed solution.

[0053]S202) Take the first mixed liquid and heat it in a water bath and stir uniformly until a transparent and uniform micelle is formed, and a second mixed liquid is obtained.

[0054]S203) Take the second mixed solution and cool it to room temperature to obtain a micellar solution.

[0055]S300) Add the nano microemulsion oil phase to the micellar solut...

Embodiment 1

[0065](1) For the preparation of antibacterial nano microemulsion, please refer toFigure 4 , Including the following steps:

[0066]A100) Add 2.50% Litsea cubeba oil and 2.50% borneol oil to the No. 1 beaker, mix them, stir evenly, and prepare and form a nano-microemulsion oil phase.

[0067]A200) Then, add 66.50-73.00% deionized water to No. 2 beaker, then add 20.00% Tween 20, 2.00-3.50% soybean lecithin, and 1.00% Tween 80 to obtain the first mixed solution;

[0068]A300) Take the first mixed solution and place it in a water bath at 70-80° C. and heat it for 5-10 minutes, and stir at a rate of 500-700 rpm until a transparent and uniform micelle is formed to prepare a second mixed solution;

[0069]A400) Take the second mixed solution and cool it to room temperature in an ice-water bath to prepare a micellar solution.

[0070]A500) Then, add the oil phase of the nano microemulsion in the No. 1 beaker to the micellar solution in the No. 2 beaker, stir evenly at a speed of 500-700 rpm, and heat it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com