Efficient machining equipment for instrument panel chassis holes

A technology for processing equipment and instrument panels, which is applied in the field of high-efficiency processing equipment for instrument panel chassis holes, can solve problems such as low efficiency and labor consumption, and achieve the effects of meeting fixed requirements, improving efficiency, and enhancing the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

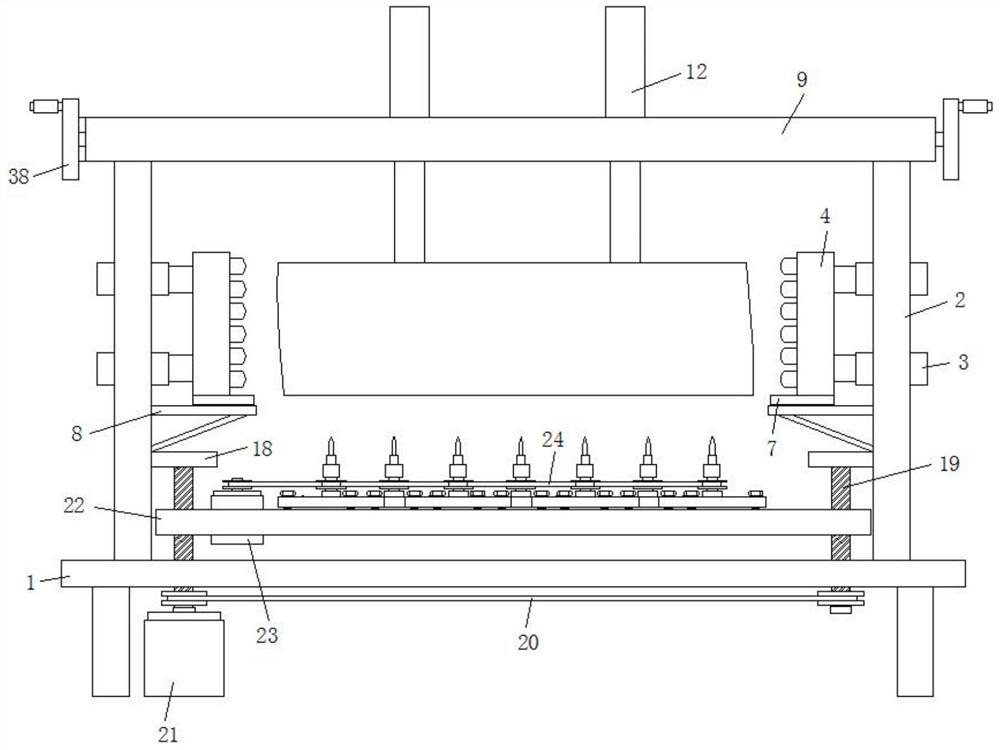

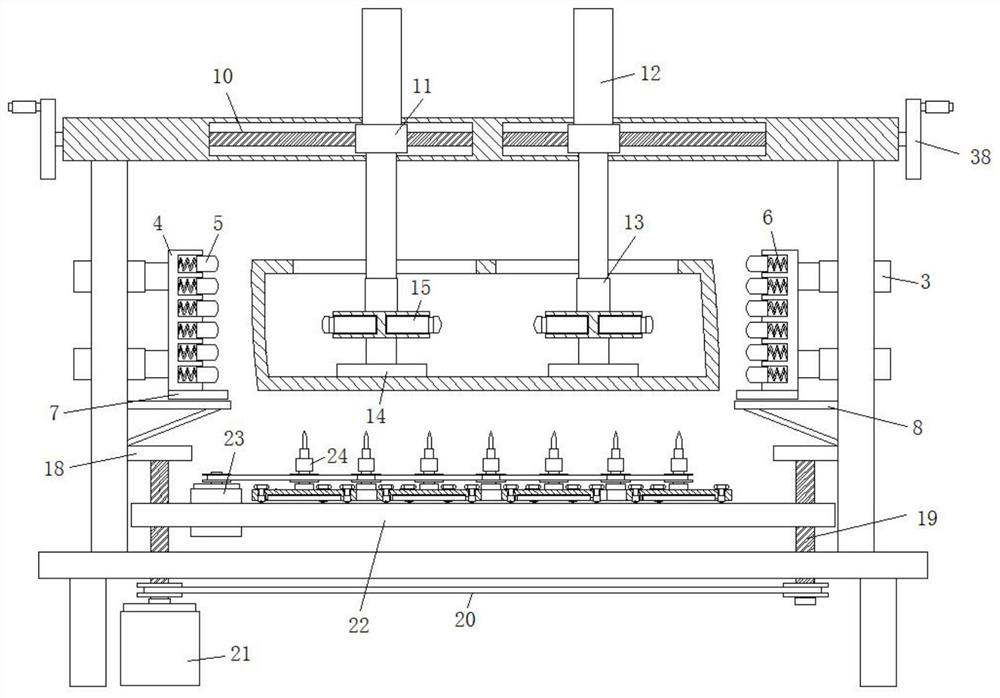

[0030] refer to Figure 1-6, a kind of high-efficiency processing equipment for instrument panel chassis holes, including a workbench 1, a support seat 2 is fixed on both sides of the top surface of the workbench 1, and a cylindrical hole is opened on both sides of the upper end of the two support seats 2, and the inner wall of the cylindrical hole is passed through a screw. The electric telescopic rod 1 is fixedly connected, and the output ends of the electric telescopic rod 3 on the same side are all fixedly connected with the pressure plate 4 by screws, and the two pressure plates 4 are provided with cylindrical grooves at the ends close to each other, and the inner walls of the cylindrical grooves are slidingly connected with extrusion Head 5, and extruding spring 6 is fixed between extruding head 5 and the bottom surface of cylindrical groove, and the bottom surface of pressing plate 4 is all fixedly connected with clamping plate 7 by screw, and the lower end of clamping p...

Embodiment 2

[0033] like Figure 5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the four corners of the bottom surface of the mounting plate 25 are provided with chute, the inner top surface of the chute is provided with threaded holes, and the inner walls of the threaded holes are connected by threads. Threaded rod two 34 are arranged, and the bottom end of threaded rod two 34 is also fixed with sliding block 35, and the bottom surface of sliding block 35 is equipped with universal wheel 36, and the top of threaded rod two 34 is all fixed with rotating block 37, and the structure of rotating block 37 is consistent with nut , and the sliding blocks 35 are all slidingly limited in the chute.

[0034] In this embodiment, the adjustment of the position of the threaded rod 2 34 can be realized by twisting the rotating block 37, and then the concealment and protrusion of the universal wheel 36 can be realized, thereby facilitating the translation and fixing of th...

Embodiment 3

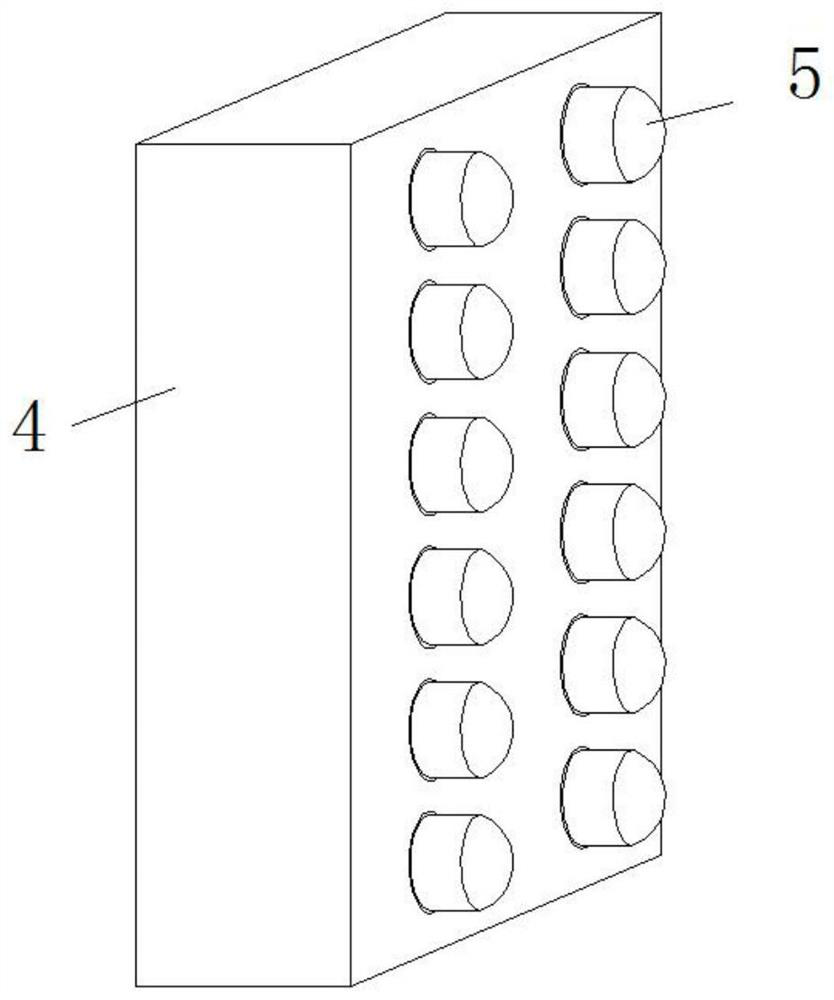

[0036] like figure 1 , 2 As shown in and 3, this embodiment is basically the same as Embodiment 1. Preferably, a plurality of extrusion heads 5 are arranged in a matrix and evenly distributed in the side wall of the pressure plate 4, and the head of the extrusion head 5 is made of rubber.

[0037] In this embodiment, under the action of the extrusion spring 6, the position dislocation of multiple extrusion heads 5 on the same side can be realized, and then the fixing operation of the instrument panel chassis with unevenness on both sides can be realized, which satisfies the different shapes of the instrument panel chassis. fixed requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com