Integral double-end forming slot milling cutter for stainless steel machining

A technology of forming grooves and stainless steel, which is applied in the direction of milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of low tool life, time-consuming tool change, low production efficiency, etc., to ensure integrity and consistency, reduce backup storage space and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

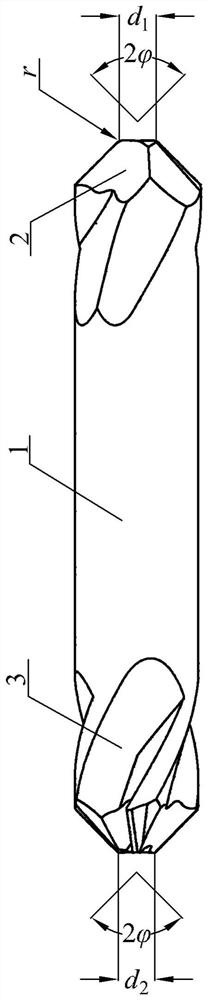

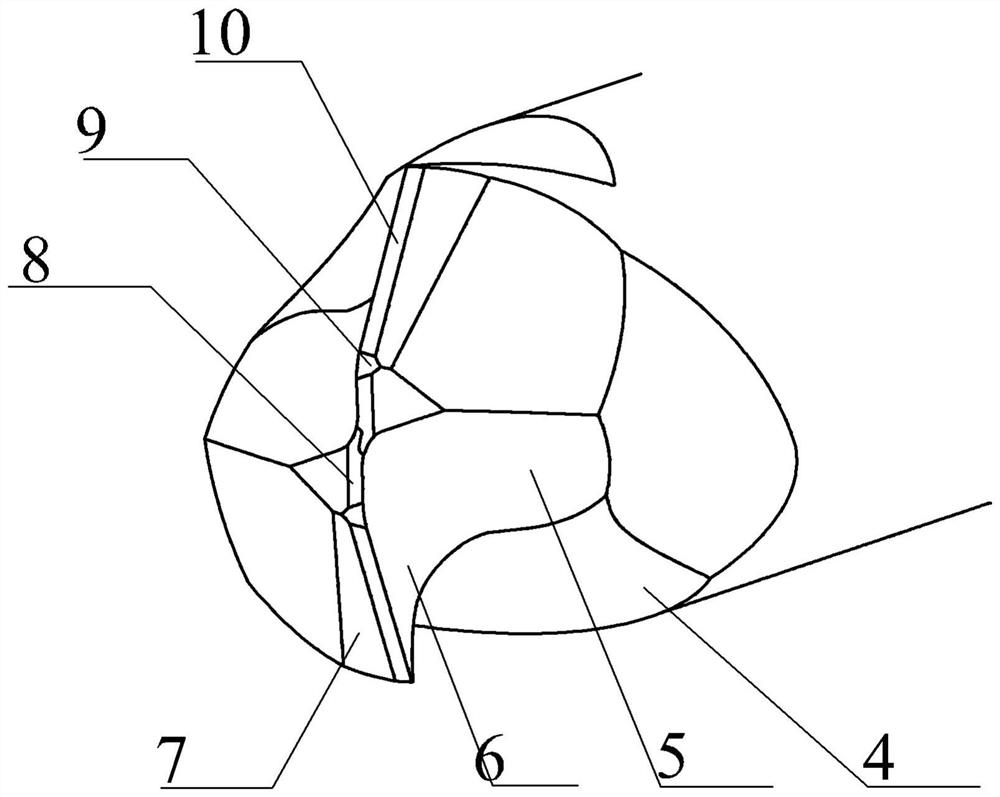

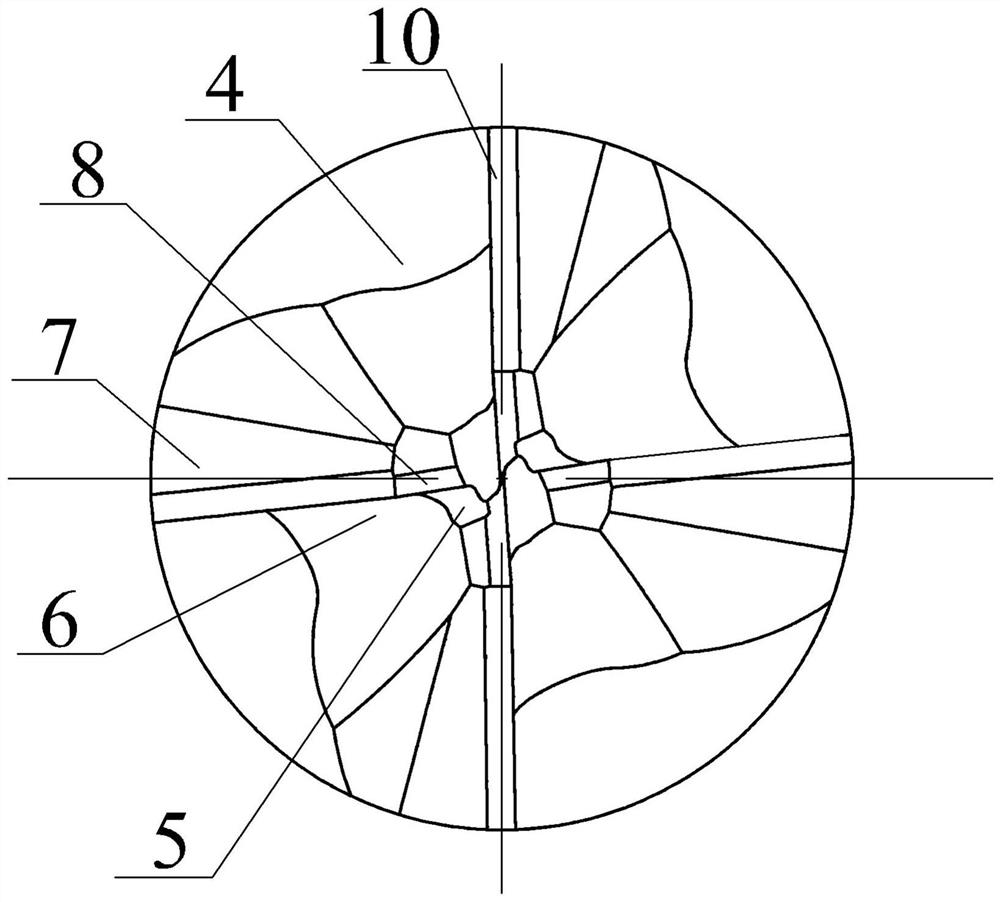

[0023] A kind of integral double-head forming groove milling cutter for stainless steel processing, see Figure 1-Figure 4 : It includes a cutter bar 1, one end of the length direction of the cutter bar 1 is provided with a rough milling edge portion 2, the other end of the length direction of the cutter bar 1 is provided with a fine milling edge portion 3, and the starting end of the blade of the rough milling edge portion 2 is flaring Trapezoidal structure, the starting end of the blade of the fine milling edge part 3 is a flared trapezoidal structure, the number of ring cutting edges of the rough milling edge part 2 is smaller than the number of ring cloth cutting edges of the fine milling edge part 3, and the material of the milling cutter is solid hard The total length L of the tool is the sum of the lengths of the tool holder 1, the rough milling edge 2 and the finish milling edge 3, and it is used for cutting trapezoidal shaped grooves of stainless steel difficult-to-mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com