Method for verifying addition amount of hydrogen peroxide for treating nitro-oxidant wastewater

A hydrogen peroxide and verification method technology, applied in chemical instruments and methods, water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as undisclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the present invention be further understood, the present invention will be further described below with reference to diagram and specific embodiment:

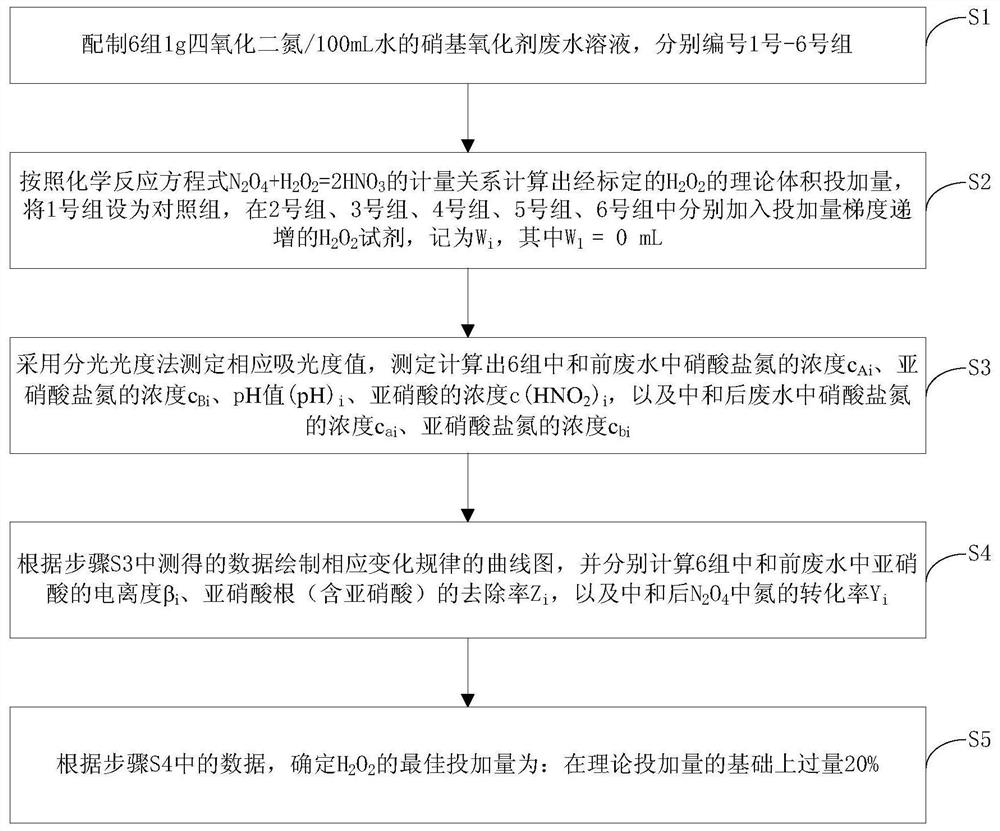

[0045] like figure 1 Shown, a kind of dosage verification method for the hydrogen peroxide that the present invention discloses is used to process nitrooxidant waste water, it comprises steps:

[0046] S1. Prepare 6 groups of nitro-oxidant wastewater solutions of 1g dinitrogen tetroxide / 100mL water, numbered respectively: Group No. 1, Group No. 2, Group No. 3, Group No. 4, Group No. 5, Group No. 6;

[0047] S2, according to the chemical reaction equation N 2 o 4 +H 2 o 2 =2HNO 3 Calculate the calibrated H 2 o 2 Theoretical volume dosage, group No. 1 was set as the control group, and H 2 o 2 Reagent, denoted as W i , where W 1 = 0 mL;

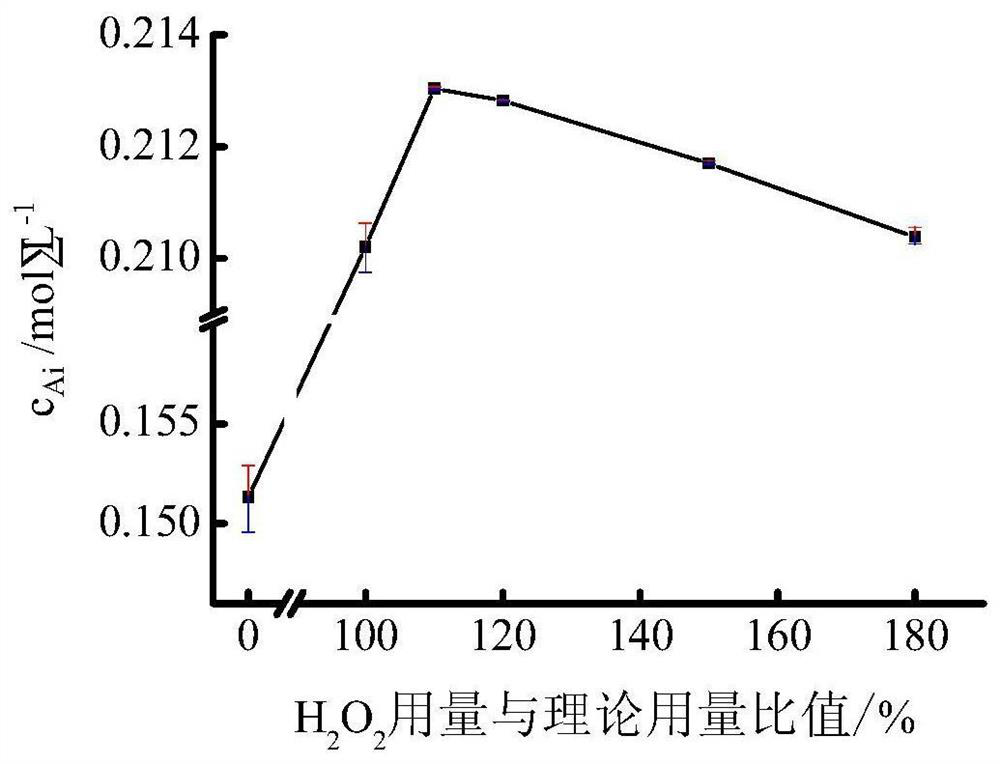

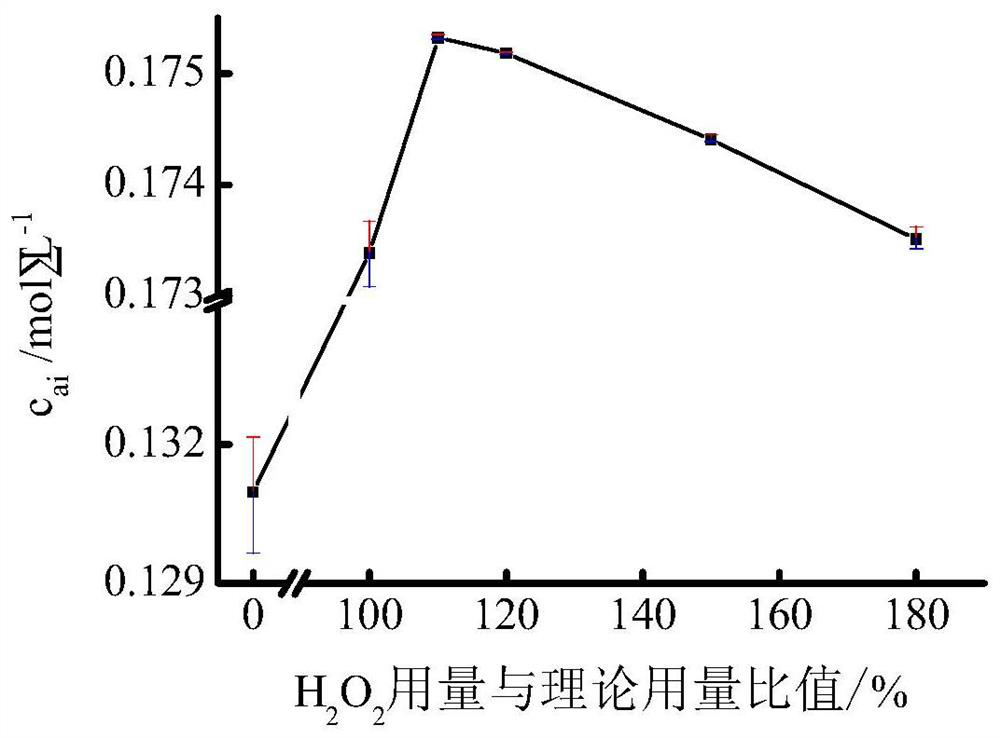

[0048] S3, using spectrophotometry to measure the corresponding absorbance value, measure and calculate the concentration c of nitrate nitrogen in the waste wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com