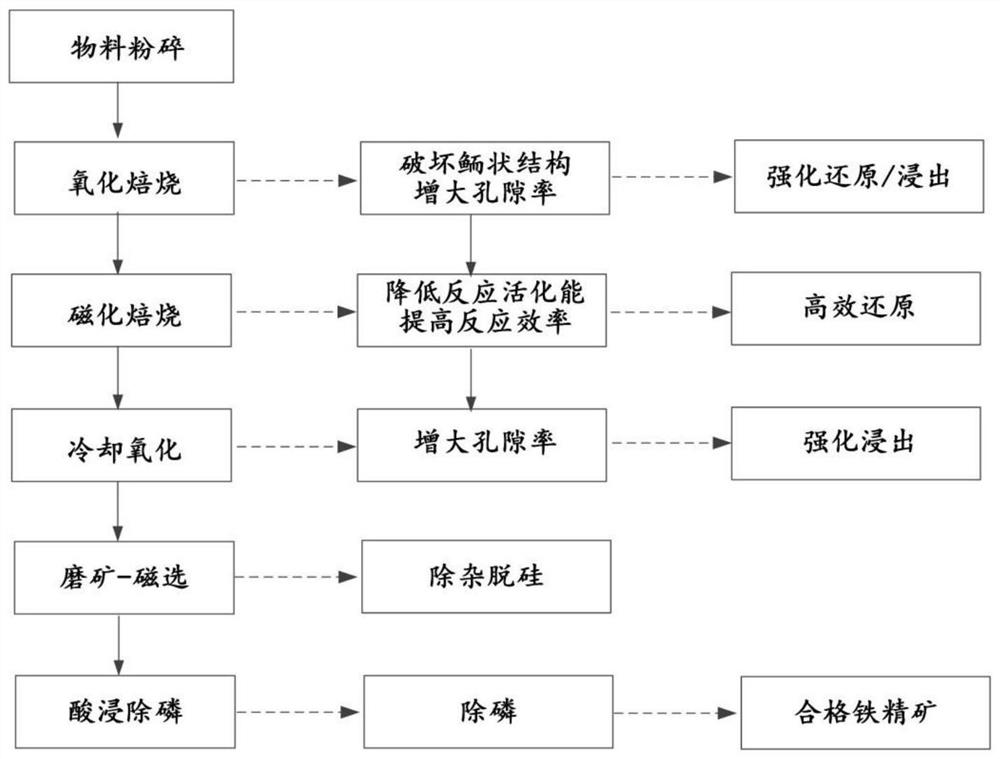

Method for extracting iron from high-phosphorus oolitic iron ore by suspension roasting and removing phosphorus by acid leaching

A suspension roasting, high-phosphorus oolitic technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of expanding the magnetic difference between iron minerals and gangue, uneven product quality, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1. Crushing: Prepare high-phosphorus oolitic hematite as raw material, its iron grade is 55.61%, and the mass percentage of phosphorus is 0.81%. After the raw material is crushed to -2mm, the material that is ground to -0.074mm accounts for 45% of the overall mass is used as roasting feed;

[0063] 2. Oxidation roasting: Send the roasted ore into the oxidation roaster for high-temperature oxidation roasting. Under the condition of oxidizing atmosphere, heat the material to 1030°C and roast for 60 minutes to obtain the oxidation roasting product;

[0064] 3. Magnetization roasting: The oxidized roasted product is roasted for 30 minutes in a reducing atmosphere at 530°C to obtain a magnetized roasted product, in which CO gas occupies the mixed gas (N 2 and CO) 30% of the total volume;

[0065] 4. Cooling oxidation: The magnetized roasted product is rapidly cooled to 200°C under the protection of nitrogen, and then exposed to air oxidation and cooled to below 90°C.

[00...

Embodiment 2

[0069] 1. Crushing: Prepare high-phosphorus oolitic hematite as raw material, its iron grade is 53.72%, and the mass percentage of P is 0.98%. After the raw material is crushed to -2mm, the material that is ground to -0.074mm accounts for 55% of the overall mass is used as roasting feed;

[0070] 2. Oxidation roasting: Send the roasted ore into the oxidation roaster for high-temperature oxidation roasting. Under the condition of oxidizing atmosphere, heat the material to 1040°C and roast for 70 minutes to obtain the oxidation roasting product;

[0071] 3. Magnetization roasting: The oxidized roasted product is roasted for 55 minutes in a reducing atmosphere at 530°C to obtain a magnetized roasted product, in which CO gas occupies the mixed gas (N 2 and CO) 25% of the total volume;

[0072] 4. Cooling oxidation: The magnetized roasted product is rapidly cooled to 190°C under the protection of nitrogen, and then exposed to air oxidation and cooled to below 90°C.

[0073] 5. Gr...

Embodiment 3

[0076] 1. Crushing: Prepare high-phosphorus oolitic hematite as raw material, its iron grade is 41.46%, and the mass percentage of P is 1.18%. After the raw material is crushed to -2mm, the material that is ground to -0.074mm accounts for 60% of the overall mass is used as roasting feed;

[0077] 2. Oxidation roasting: Send the roasted ore into the oxidation roaster for high-temperature oxidation roasting. Under the condition of oxidizing atmosphere, heat the material to 1050°C and roast for 70 minutes to obtain the oxidation roasting product;

[0078]3. Magnetization roasting: the oxidized roasted product is roasted in a reducing atmosphere at 520°C for 30 minutes to obtain a magnetized roasted product, in which CO gas accounts for the mixed gas (N 2 and CO) 40% of the total volume;

[0079] 4. Cooling oxidation: The magnetized roasted product is rapidly cooled to 240°C under the protection of nitrogen, and then exposed to air oxidation and cooled to below 90°C.

[0080] 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com