A silicon carbide crystal removal device

A silicon carbide and crystal technology is applied in the field of silicon carbide crystal removal devices, which can solve the problems of cracking and uneven crystal shedding, and achieve the effect of reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

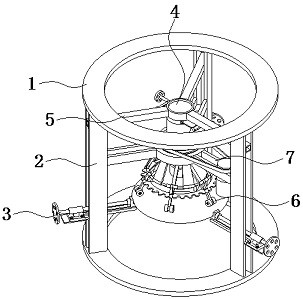

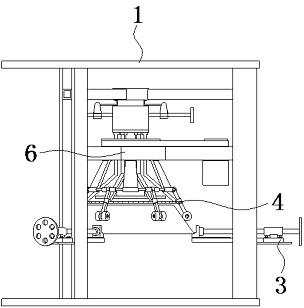

[0026] Embodiment one, such as Figure 1-8 As shown, a device for removing a silicon carbide crystal includes two supporting plates 1 and three connecting rods 2, the three connecting rods 2 are located between the two supporting plates 1, and the upper and lower ends of the three connecting rods 2 are respectively connected to The sides of the two support plates 1 close to each other are fixedly connected, and a buffer pad can be placed inside the support plate 1 below.

[0027] The lower ends of the three connecting rods 2 are all equipped with a clamping mechanism 3, and an extruding mechanism 4 is arranged between the upper ends of the three connecting rods 2. The extruding mechanism 4 is fixedly connected with the three connecting rods 2 through three horizontal plates A5, and the three connecting rods 2 are fixedly connected. A striking mechanism 6 is arranged between the connecting rods 2, and the striking mechanism 6 is fixedly connected with the three connecting rods ...

Embodiment 2

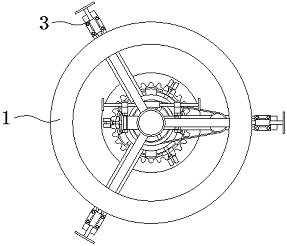

[0030] Embodiment two, such as Figure 1-7 As shown, the clamping mechanism 3 includes a guide rail 301, a clamping block 302, a threaded rod B303 and a threaded sleeve B304, the guide rail 301 is fixedly connected with the connecting rod 2, the lower end of the clamping block 302 is slidingly connected with the guide rail 301, and the threaded sleeve B304 is connected with the guide rail 301. The outer end is fixedly connected, one end of the threaded rod B303 is rotatably connected with the clamp block 302, and the other end of the threaded rod B303 passes through the threaded sleeve B304 and is threadedly connected with it.

[0031]When in use, the crucible or the seed crystal bracket can be fixed by adjusting the clamping mechanism 3, and the pulley 603 is driven to rotate by controlling the rotation of the motor 602, and then the fixed ring 604 starts to rotate under force, driving the rocker 607 to rotate, and the rocker When 607 rotates along the special-shaped wheel 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com