Method and system for storing energy by compressing metallurgical gas

A gas and metallurgical technology, applied in the field of energy storage in metallurgical enterprises, can solve the problems of no economic value and social value of electric energy, and utilization of peak and valley characteristics of electric power demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] See figure 1 As shown, the method for compressing metallurgical gas energy storage provided by the embodiment of the present invention:

[0050] S101, during the valley electricity period, use a gas compressor to compress the metallurgical gas and store it in a gas compression container;

[0051] S102. During the peak power or flat power period, the compressed metallurgical gas is released from the gas compression container and enters the gas expansion generator set for power generation.

[0052]According to the embodiment of the present invention, during the off-peak power period, the gas compressor is used to compress the metallurgical gas and store it in the gas compression container; during the peak power or flat power period, the compressed metallurgical gas is released from the gas compression container, Enter the gas expansion generator set for power generation. In this way, gas compressors are used to compress and store the excess gas in the gas cabinets of ir...

Embodiment 2

[0074] Since the system for compressing metallurgical gas energy storage provided by the present invention corresponds to the specific implementation of the aforementioned method for compressing metallurgical gas energy storage, the system for compressing metallurgical gas energy storage can realize this by performing the process steps in the specific implementation of the above method. The purpose of the invention, therefore, the explanations in the specific embodiments of the method for compressing metallurgical gas energy storage are also applicable to the specific embodiments of the system for compressing metallurgical gas energy storage provided by the present invention, so in the following specific embodiments of the present invention will be No longer.

specific Embodiment approach

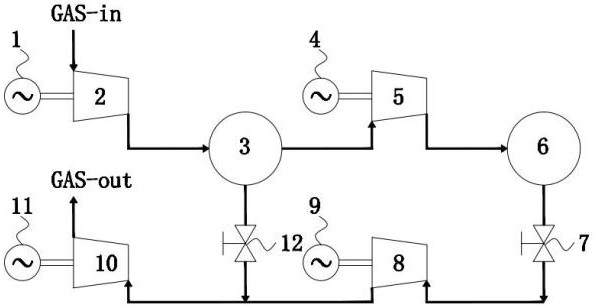

[0076] The low-pressure gas compressor motor 1 is used to convert the low-cost electric energy of the grid into mechanical energy during the off-peak period, and then drive the low-pressure gas compressor 2 to compress the metallurgical gas and store it in the low-pressure gas container 3; similarly, the high-pressure gas compressor The electric motor 4 is used to convert the low-cost electric energy of the grid into mechanical energy during the off-peak period, and then drive the high-pressure gas compressor 5 to further compress the metallurgical gas and store it in the high-pressure gas container 6 . During the peak electricity period, open the valve 7, send the high-pressure gas into the expander 8 to do work, and then drive the generator 9 to generate electricity; similarly, the low-pressure gas that has been expanded from the 8 is sent to the expander 10 to do work, and then drives the power generation The generator 11 generates power; the gas stored in the low-pressure g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com