Plastic lining fiber reinforced composite material high-pressure hydrogen storage cylinder

A fiber-reinforced and composite material technology, applied in the field of plastic-lined fiber-reinforced composite high-pressure hydrogen storage cylinders, can solve the problems of complex manufacturing, high processing precision, and high cost, and achieve good compactness, high precision, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

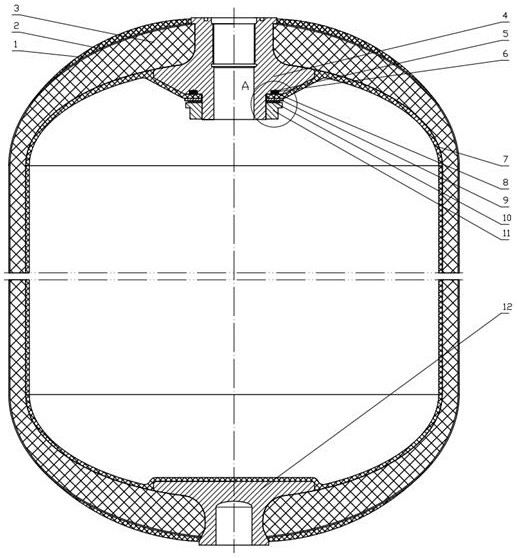

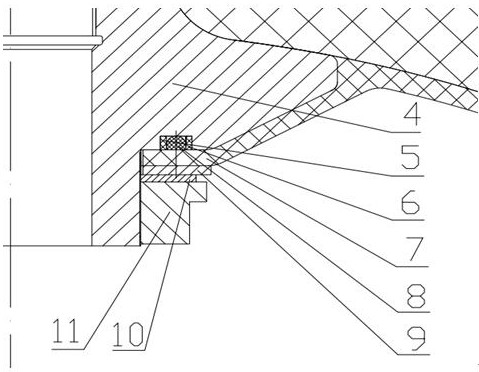

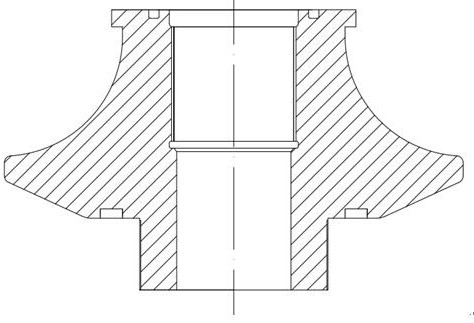

[0027] Such as figure 1 , figure 2 Shown, the present invention comprises plastic liner 7, metal gas cylinder opening end 4 and metal gas cylinder tail end 12; The axial lower end surface of the opening end 4 is bonded with an adhesive, the lower end of the plastic lining 7 is bonded to the upper end surface of the tail end 12 of the metal gas cylinder, and the fiber reinforced layer 3 at the upper end of the plastic lining 7 is connected to the shaft of the metal gas cylinder opening end 4. The upper end surface is attached, the fiber reinforced layer 3 at the lower end of the plastic liner 7 is attached to the axially lower end surface of the metal gas cylinder tail end 12, the outer side of the fiber reinforced layer 3 is wrapped with a glass fiber protective layer 2, and the two ends of the metal gas cylinder The outer side of the glass fiber pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com