Patents

Literature

34results about How to "Increase gas storage density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

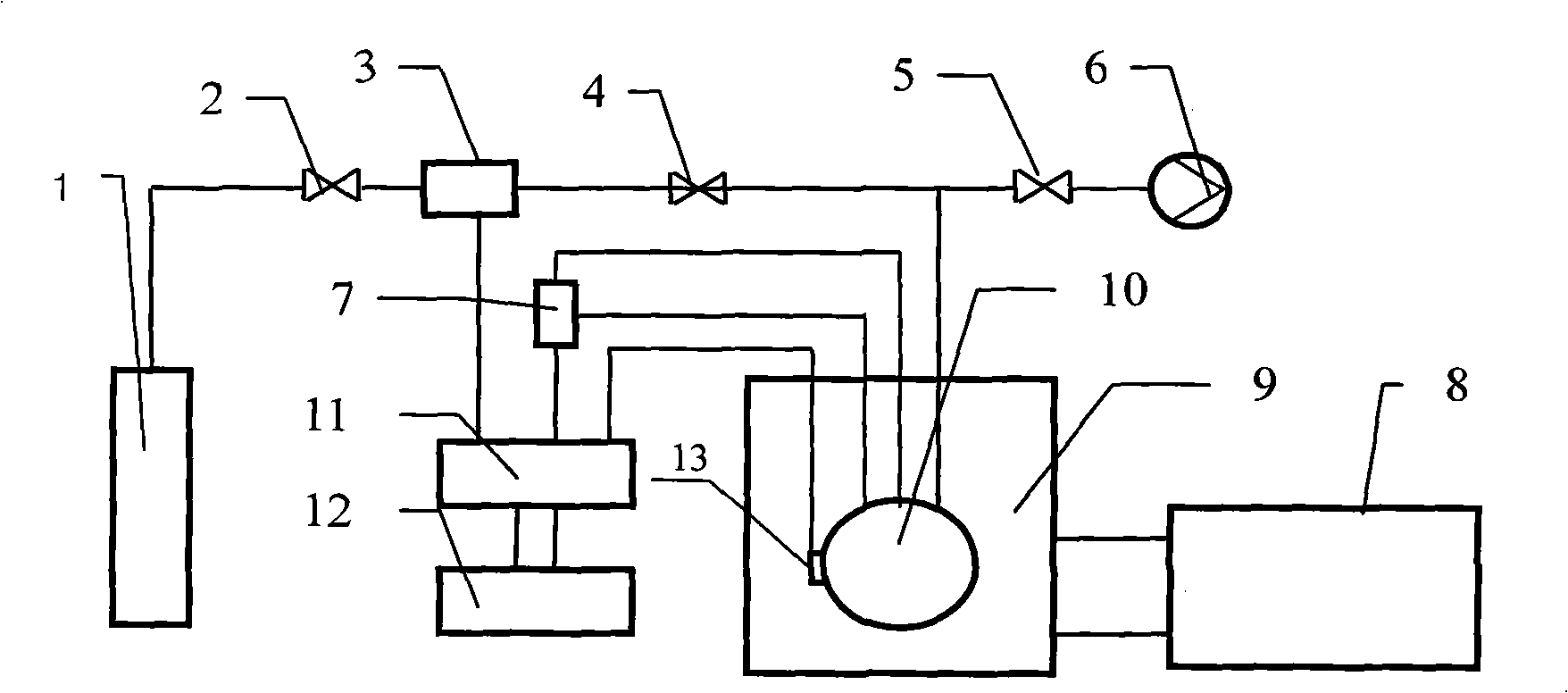

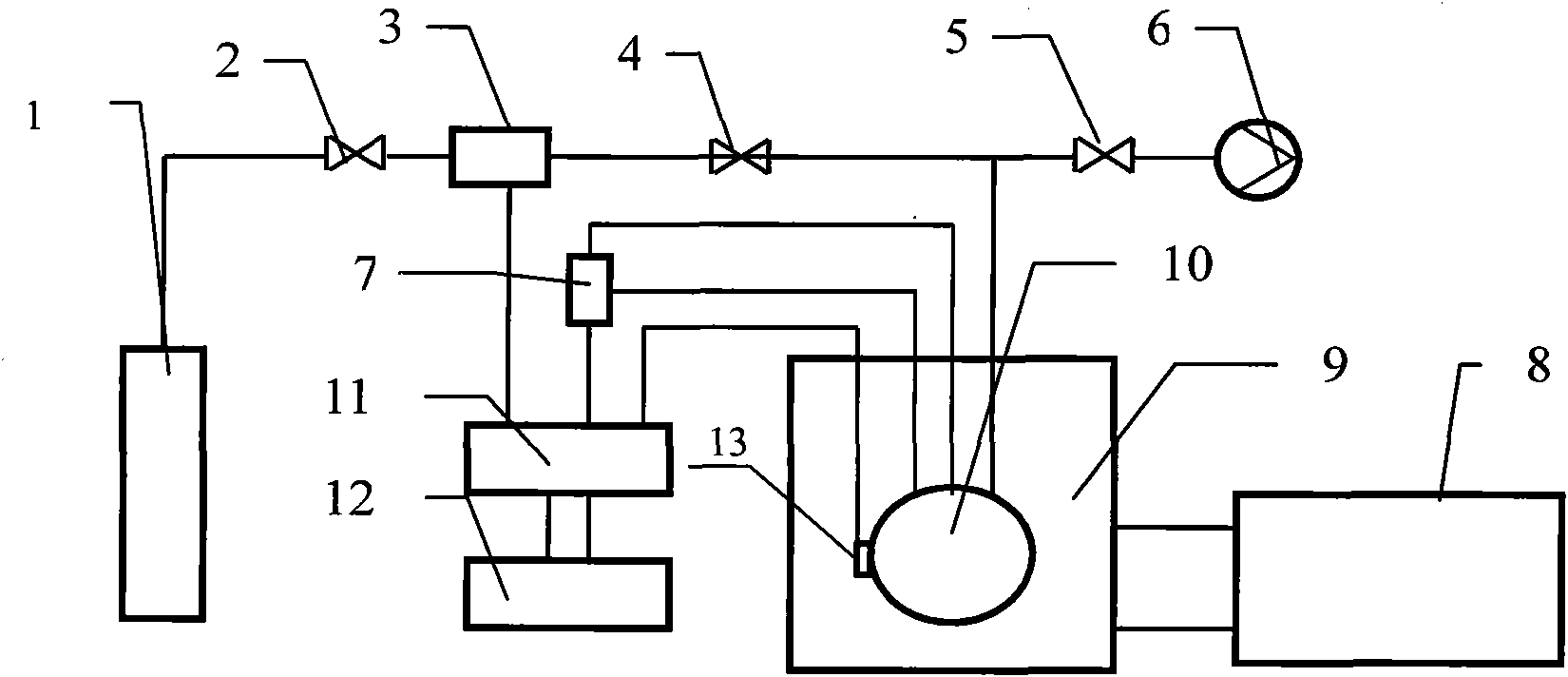

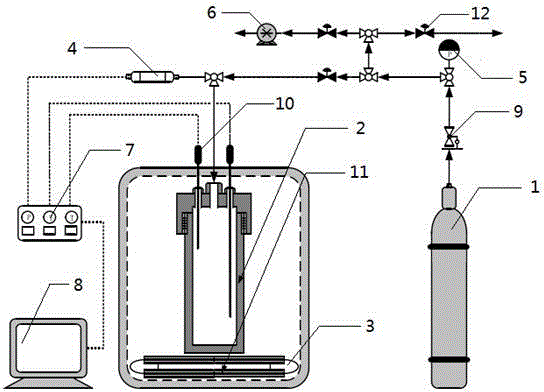

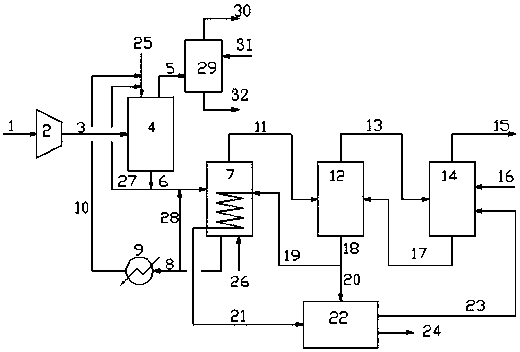

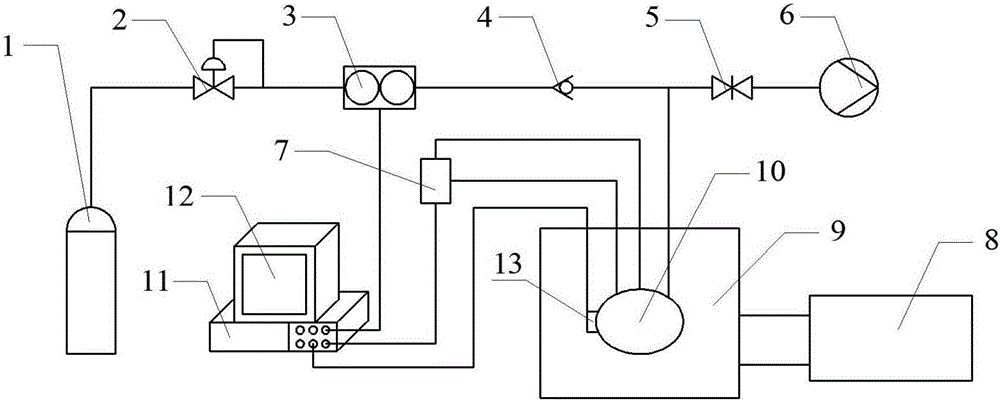

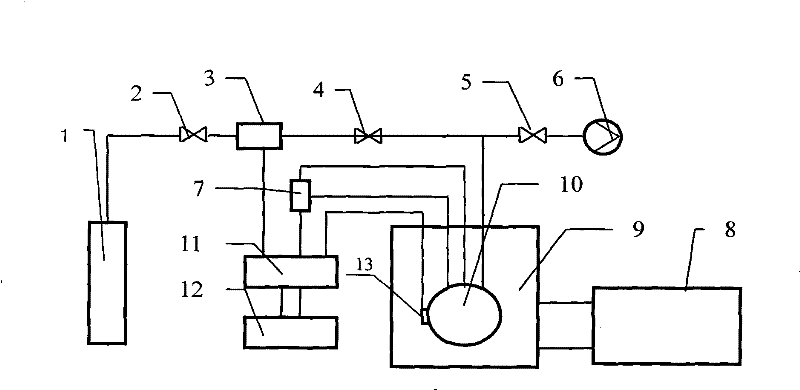

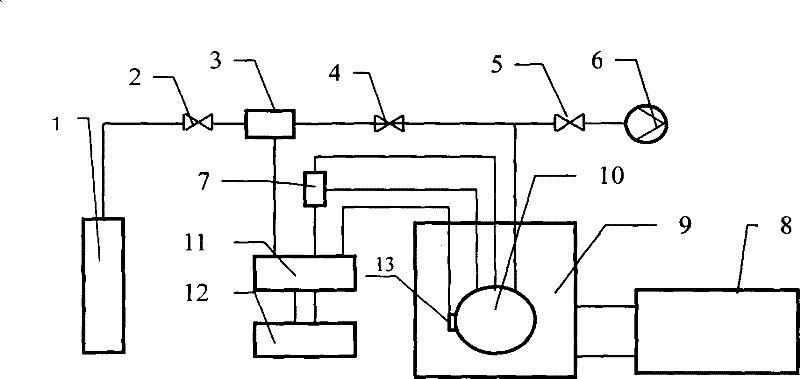

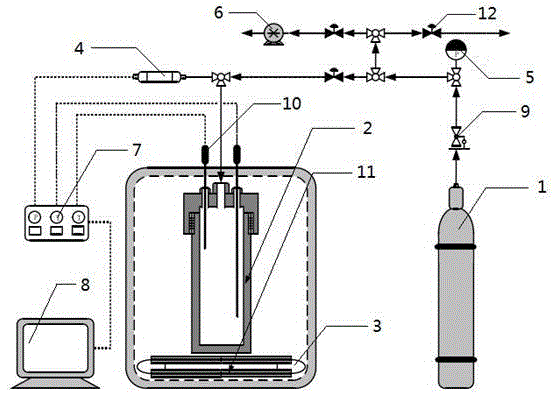

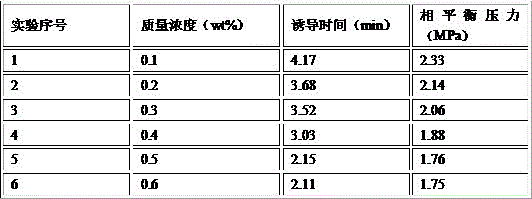

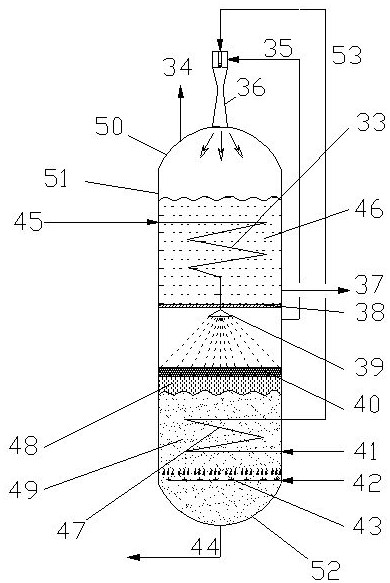

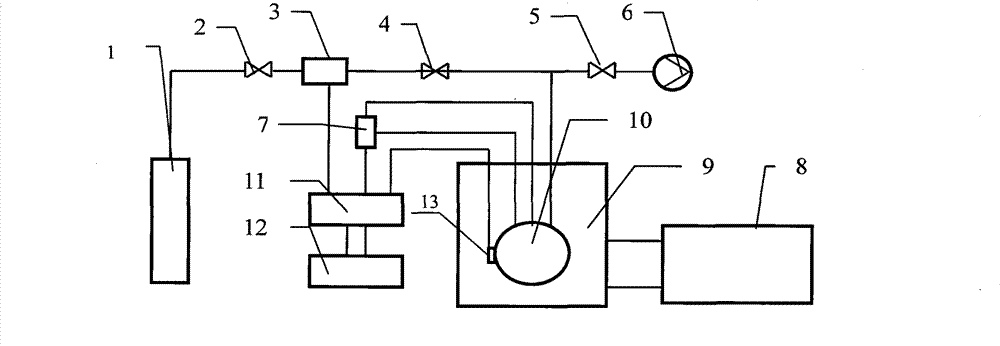

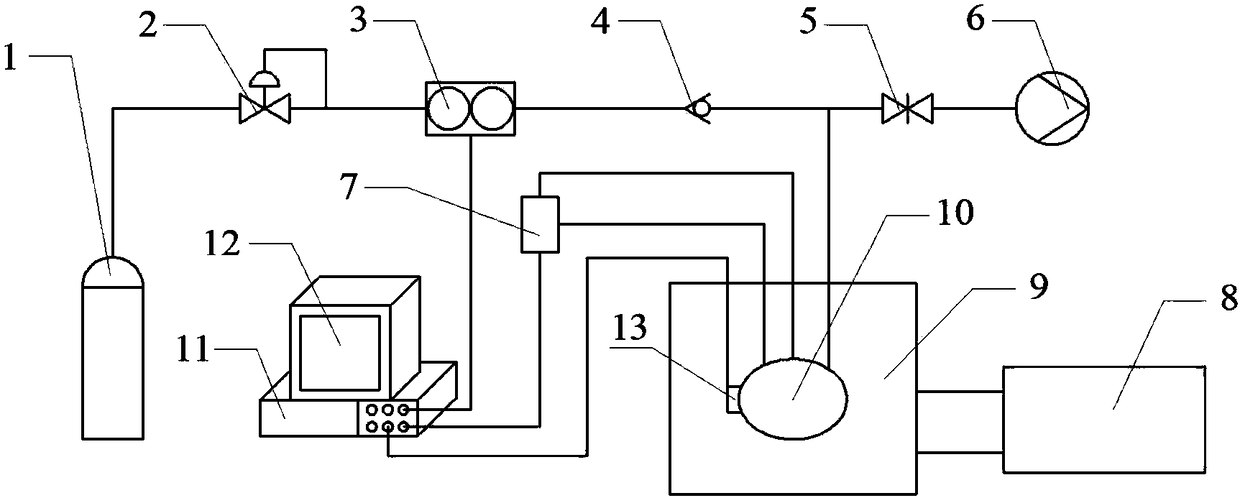

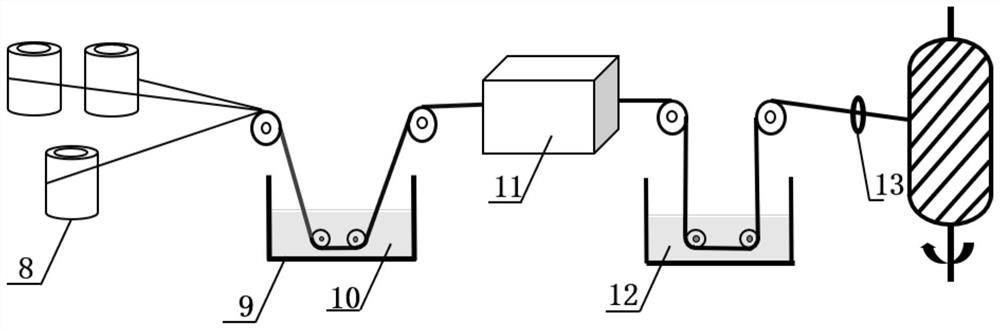

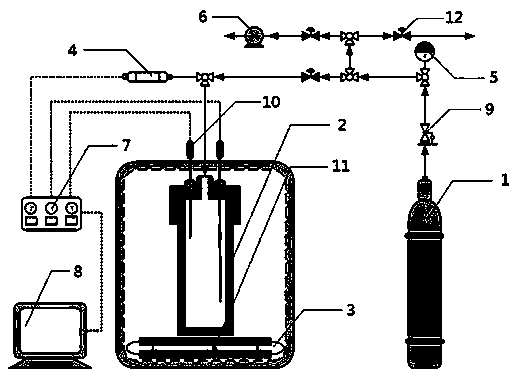

Method for preparing gas hydrate accelerant

The invention provides a method for preparing gas hydrate accelerant, which takes a high pressure gas cylinder as gas source; the high pressure gas cylinder is regulated to have proper pressure by a pressure regulating valve, and the consumed natural gas is calculated by a mass flowmeter; the temperature and the pressure in a reactor are monitored by a pressure and temperature transmitter; thermostatic waterbath is used for controlling the temperature of the liquid in a trough, thus regulating the temperature in the reactor; a data acquisition system and a computer are used for collecting data, and an opto-electrical lens is used for monitoring the forming situation of hydrate in the reactor. The composite accelerant is low in cost and little in dosage, ensures the generating condition of the hydrate to be reduced, the time to be shortened and the gas storage quantity to be increased, and effectively improves the economic benefit of the production of the hydrate.

Owner:溧阳常大技术转移中心有限公司

Hydrate accelerant and application thereof in preparing high-gas-storage-density gas hydrate

ActiveCN104974713ANon-toxicNo pollution in the processOther chemical processesGaseous fuelsVolumetric Mass DensityHigh pressure

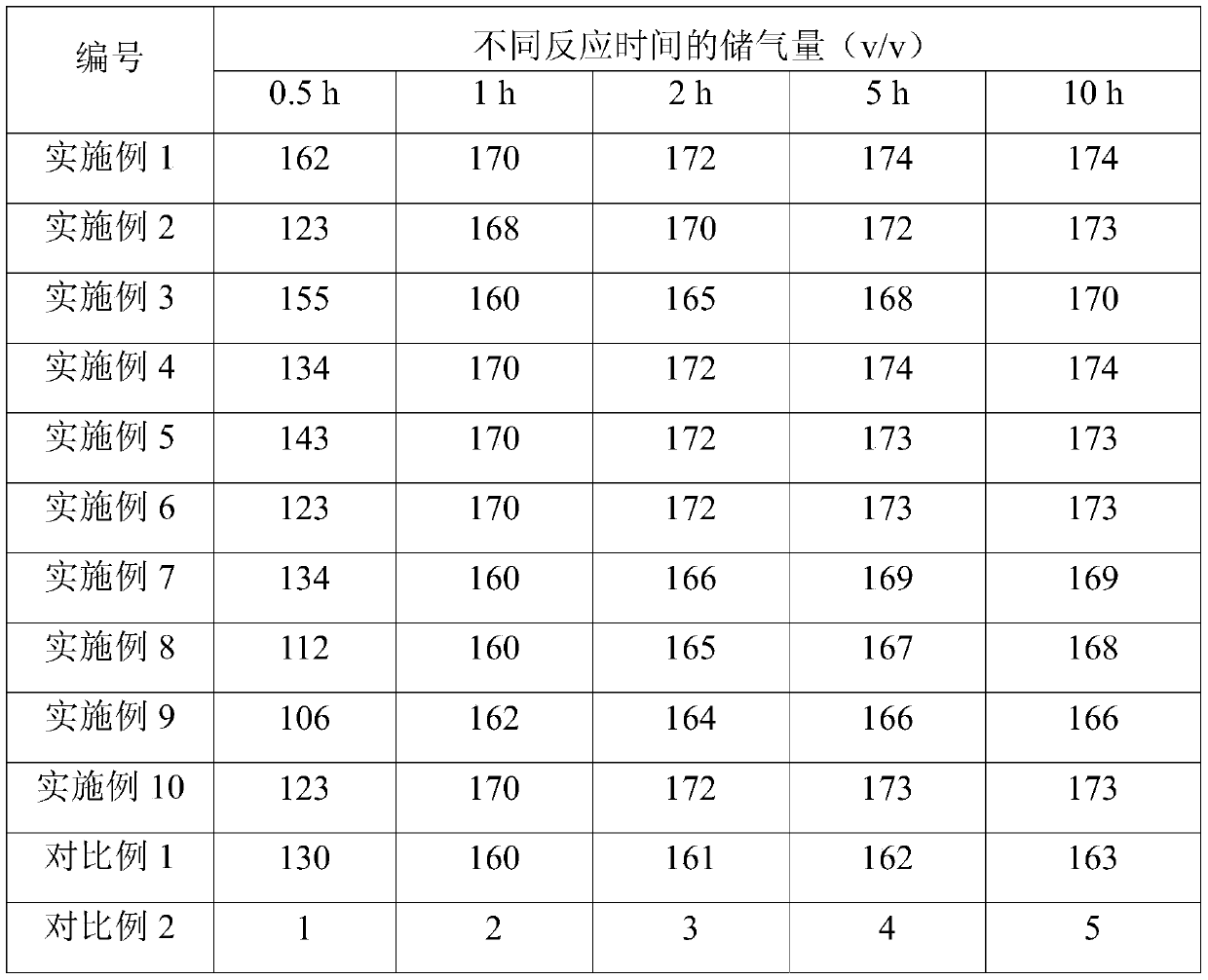

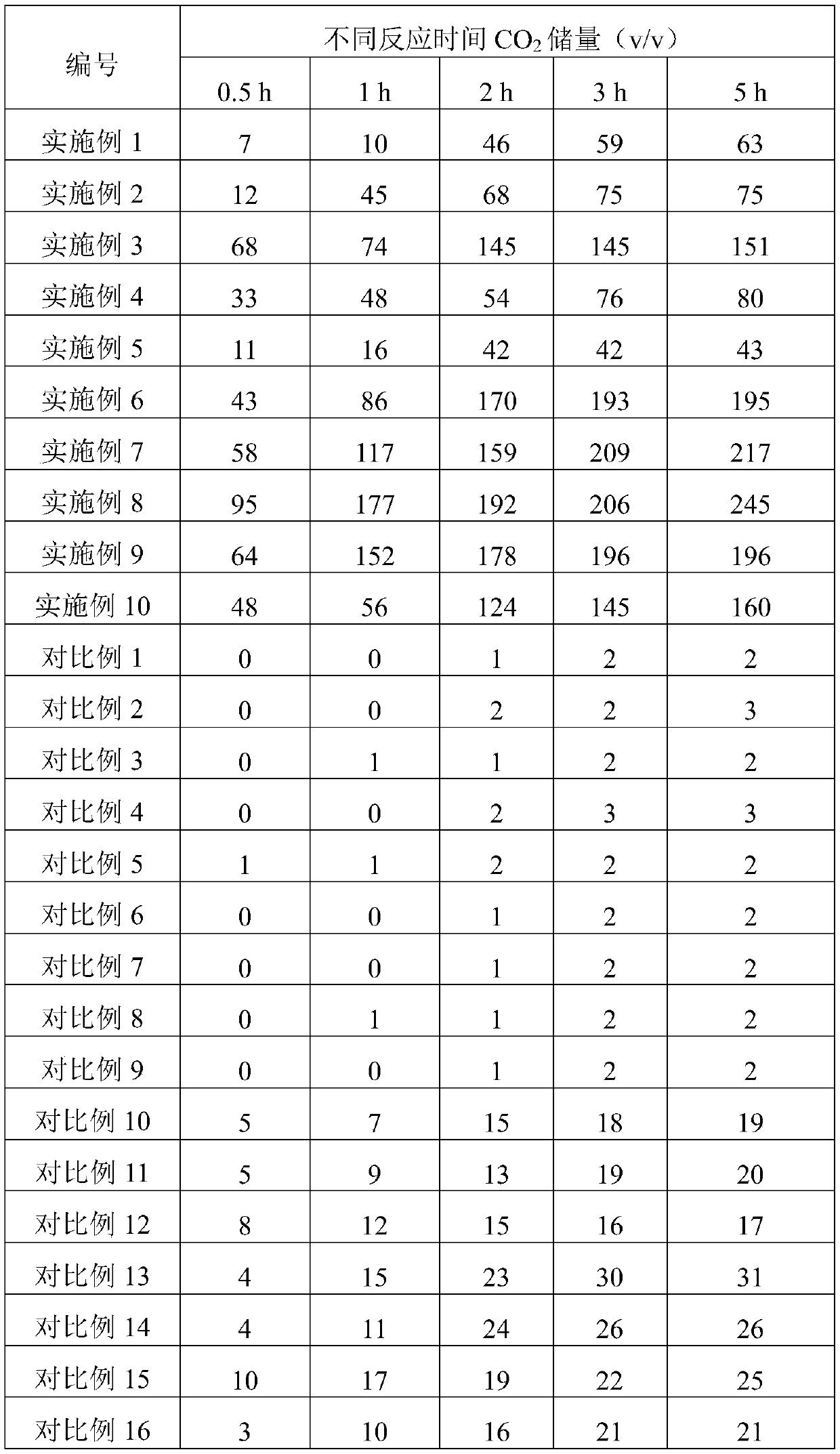

The invention relates to the technical field of energy materials, and discloses a hydrate accelerator and an application thereof in preparing a high-gas-storage-density gas hydrate. The accelerant comprises amino acid and water, and is prepared by well mixing 100 parts by mass of water and 0.05-5 parts by mass of amino acid. The application comprises the specific steps that 100 parts by mass of water and 0.05-5 parts by mass of amino acid are well mixed, such that an accelerant water solution is obtained; the accelerant water solution is placed in an autoclave; high-pressure gas is delivered in under a low temperature; and a reaction is allowed for a period of time, such that the high-gas-storage-density solid gas hydrate is obtained. The accelerant provided by the invention is green and environment-friendly. With the accelerant, hydration induction time can be reduced, gas storage capacity can be increased, and gas storage density can be improved. The accelerant provided by the invention also has the advantages of low price, low dosage, and wide source. The accelerant is recyclable, and has no special requirement on temperature and pressure conditions. The method for preparing the high-gas-storage-density gas hydrate is fast, highly efficient, simple, and easy to realize.

Owner:SOUTH CHINA UNIV OF TECH

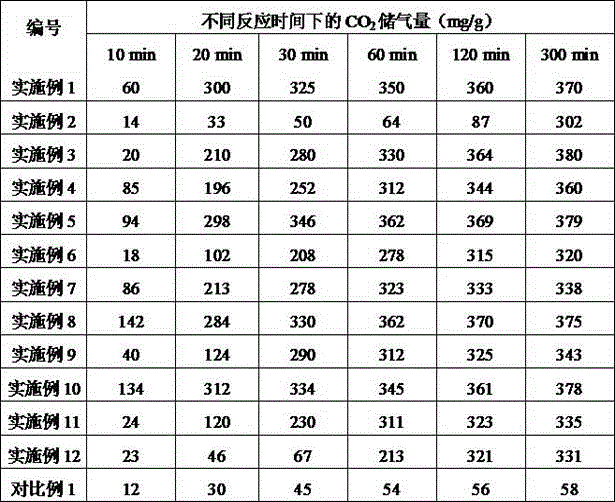

Application of amino acid as hydrate accelerant and application of amino acid as hydrate accelerant in capturing and sealing of carbon dioxide

InactiveCN105944508AReduce dosageNo pollution in the processDispersed particle separationHigh pressureAqueous solution

The invention discloses application of amino acid as a hydrate accelerant and application of amino acid as the hydrate accelerant in capturing and sealing of carbon dioxide. The application of amino acid as the hydrate accelerant is particularly application of amino acid as a CO2 hydrate accelerant. The application of amino acid as the hydrate accelerant in the capturing and the sealing of carbon dioxide comprises the following steps: (1) uniformly mixing 100 parts by weight of water and 0.01-3 parts by weight of amino acid, so as to obtain an amino acid water solution; (2) injecting the amino acid water solution into a high-pressure reaction kettle; (3) introducing high-pressure CO2 gas into the high-pressure reaction kettle to react, so as to obtain solid CO2 hydrate with high air storage density, thereby realizing the efficient capturing and sealing of carbon dioxide. By utilizing amino acid as the CO2 hydrate accelerant, the application meets the scientific concept of ''environmental friendliness'' and economic and efficient, the hydration induction time can be greatly shortened, and the gas capturing capacity can be increased.

Owner:SOUTH CHINA UNIV OF TECH

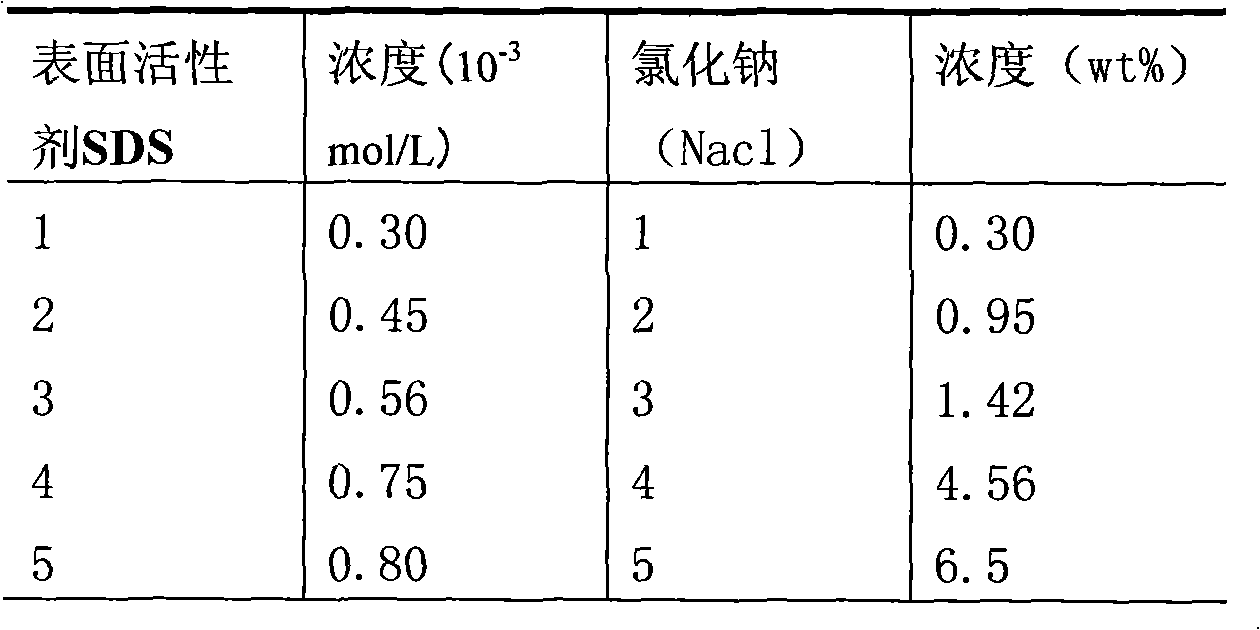

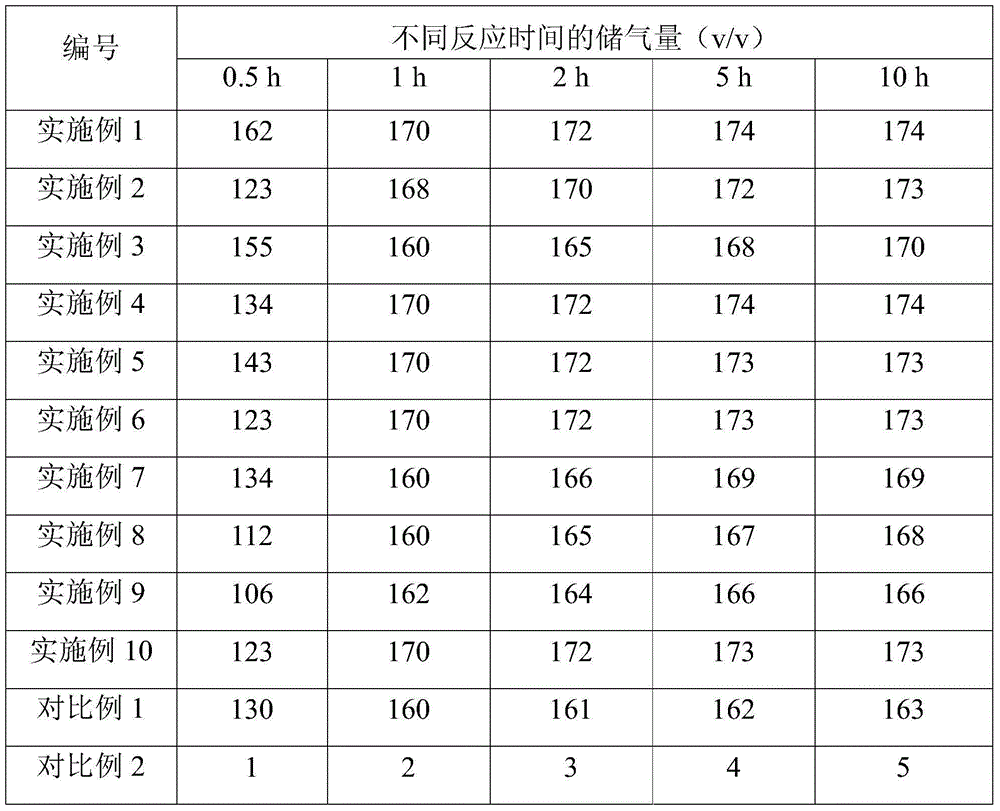

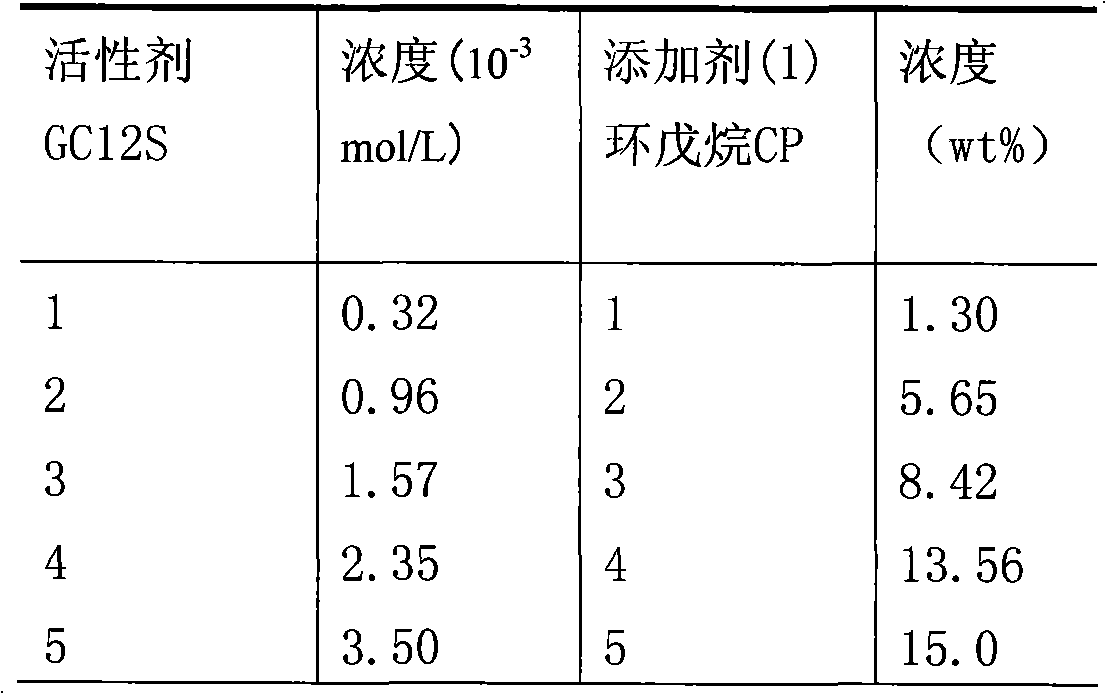

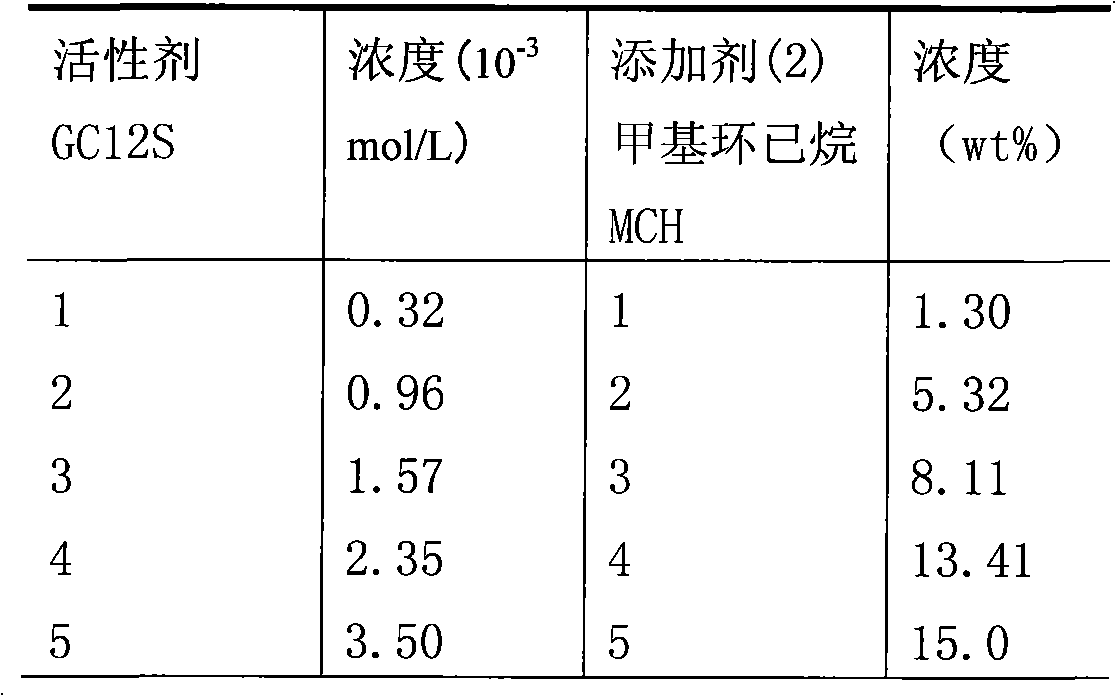

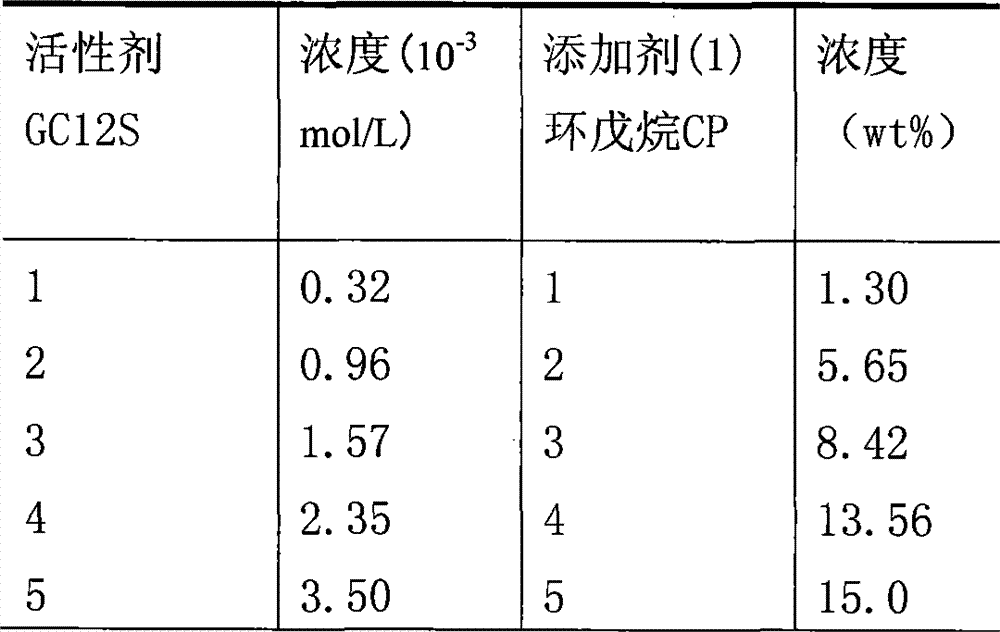

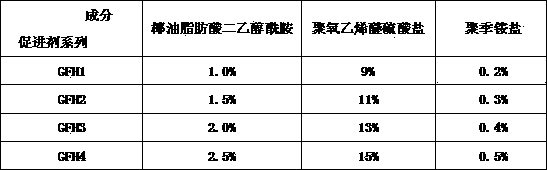

Method for preparing composite hydrate accelerant

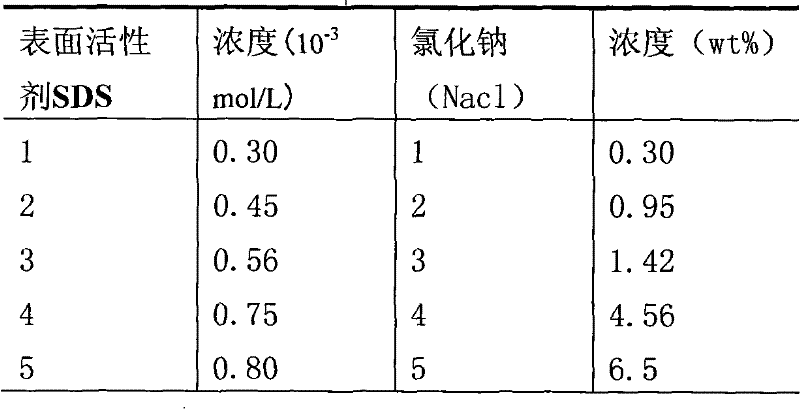

The invention relates to a method for preparing a composite hydrate accelerant. The composite accelerant is characterized by being prepared by mixing cyclopentane or methyl cyclohexane serving as a kinetic accelerant and 2-butyl octyl sodium sulfate serving as a surfactant, wherein the percentage by mass of the cyclopentane or methyl cyclohexane in a solvent is 1.3 to 15.0, and the concentration of the surfactant 2-butyl octyl sodium sulfate in the solvent is 0.32*10<-3> to 9.5*10<-3> mol / L; and 0.02 to 0.78 mass percent of sodium chloride is added into the mixture. In the method, a high-pressure gas cylinder is taken as a gas source, a pressure is properly adjusted through a pressure adjustment valve, consumed gas is metered by a mass flow meter, a temperature and the pressure in a reactor are monitored by pressure and temperature transducers, and the temperature of liquid in a water tank is controlled by means of a thermostatic water bath, so that the temperature in the reactor is adjusted; and data is acquired by a data acquisition system and a computer, and the forming condition of a hydrate in the reactor is monitored by a photoelectric lens. The method for preparing the composite hydrate accelerant not only can reduce the forming condition of the hydrate, but also can shorten the formation time of the hydrate and improve the gas storage capacity of the hydrate.

Owner:溧阳常大技术转移中心有限公司

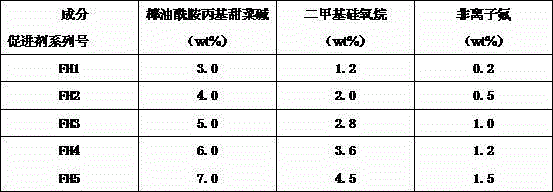

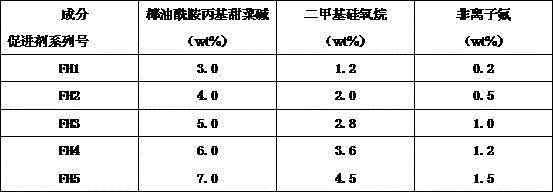

Hydrate promoter and preparation method thereof

ActiveCN104857891ALower spawn conditionsReduce build timeOther chemical processesTransportation and packagingOLEAMIDOPROPYL BETAINEBetaine

The invention belongs to the technical field of production promotion and utilization of gas hydrates, and particularly relates to a hydrate promoter and a preparation method thereof. The hydrate promoter is prepared by mixing cocamidopropyl betaine, dimethyl siloxane and a nonionic fluorinated surfactant which are used as additives with deionized water at the temperature ranging from 65 DEG C to 85 DEG C for 30-40 min; the solvent comprises, in percentage by mass, 3-7% of the cocamidopropyl betaine, 1.2-4.5% of the dimethyl siloxane, 0.2-1.5% of the nonionic fluorinated surfactant and the balance of the deionized water. The hydrate promoter can be widely applied to fields of gas hydrate storage and transportation technologies, gas hydrate separation technologies, sea water desalination and the like; the hydrate promoter is low in cost and low in consumption, hydrate generation conditions are reduced, time is shortened, the gas storage capacity is improved, and the economic benefit of hydrate production is effectively increased.

Owner:邳州市博睿投资管理有限公司

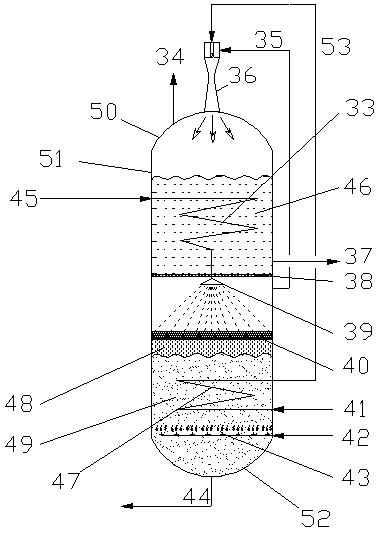

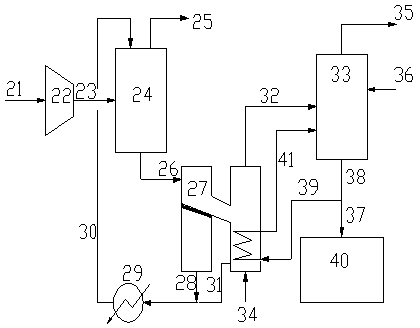

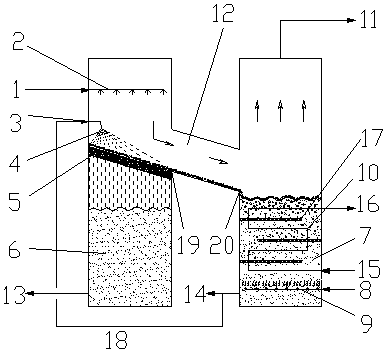

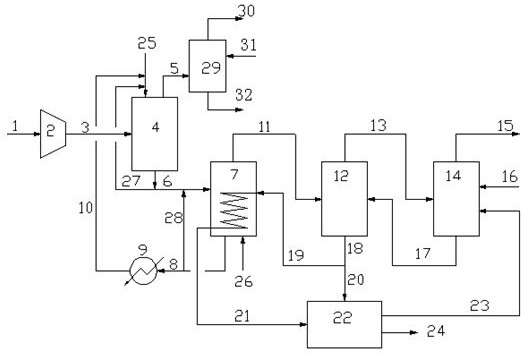

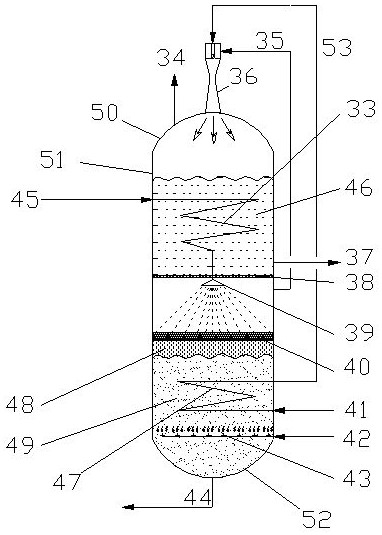

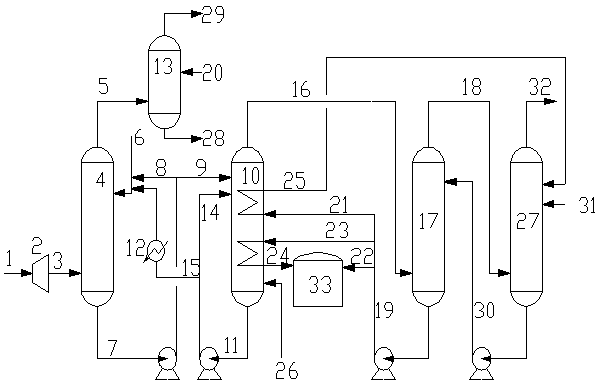

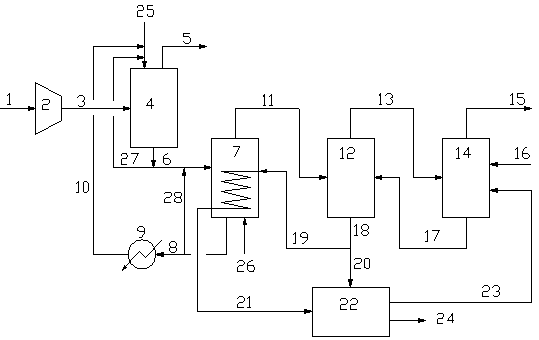

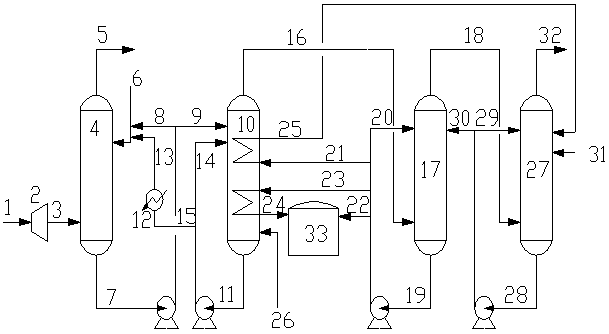

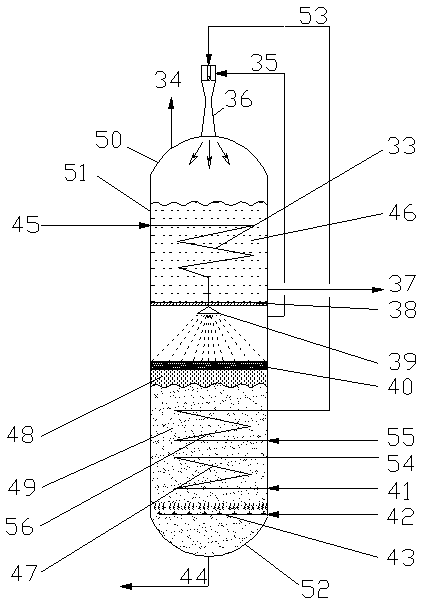

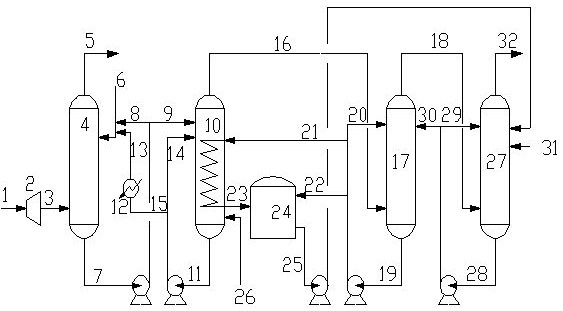

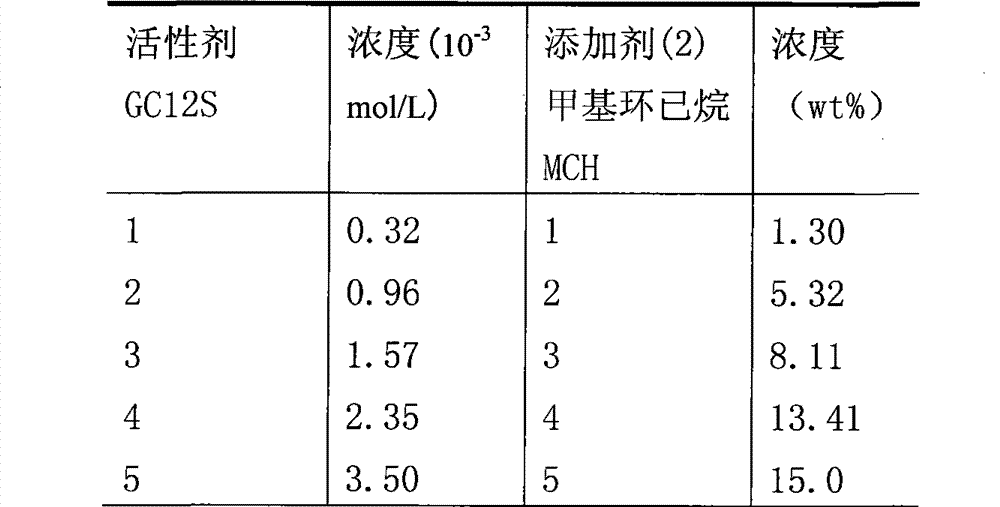

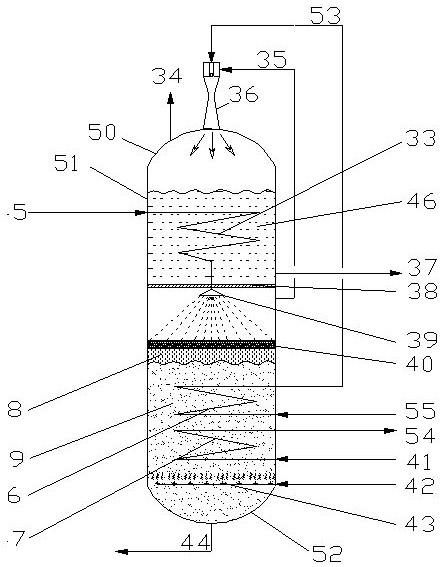

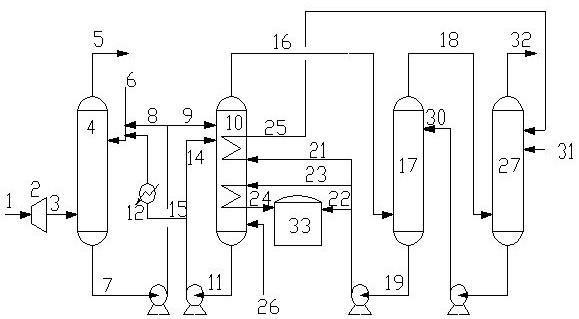

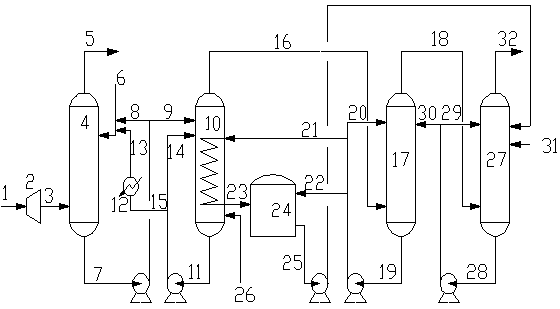

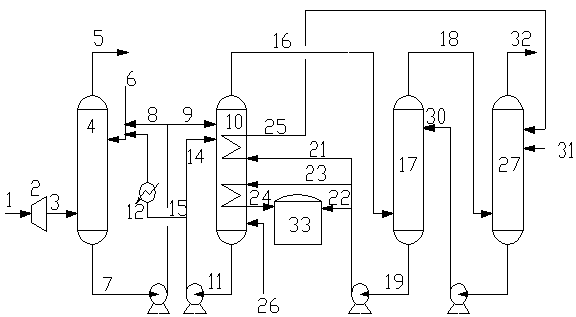

Treating method and device for carbon dioxide and hydrogen sulfide containing gas

ActiveCN108722148AReasonable useReduce energy consumptionGas treatmentDispersed particle separationProduct gasChemical products

The invention discloses a treating method and device for carbon dioxide and hydrogen sulfide containing gas. The device comprises a hydration reactor, a hydrate decomposing device, an exhaust gas treating device, a first-stage absorbing reactor, a second-stage absorbing reactor and a product tank. The invention further provides a method for treating the carbon dioxide and hydrogen sulfide containing gas through the abovementioned device. With the adoption of the device and the method, NaHS products meeting national quality standard can be produced while acidic gas standardized discharging is realized; the environment treatment and the production process of chemical products are integrated. Compared with the prior art, the method has the advantages that the carbon dioxide and hydrogen sulfide containing gas can be economically and efficiently pretreated; the energy in the technical process can be reasonably utilized, so that the energy consumption is extremely decreased; the whole treatment process is environmentally friendly, reliable, and free of three wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

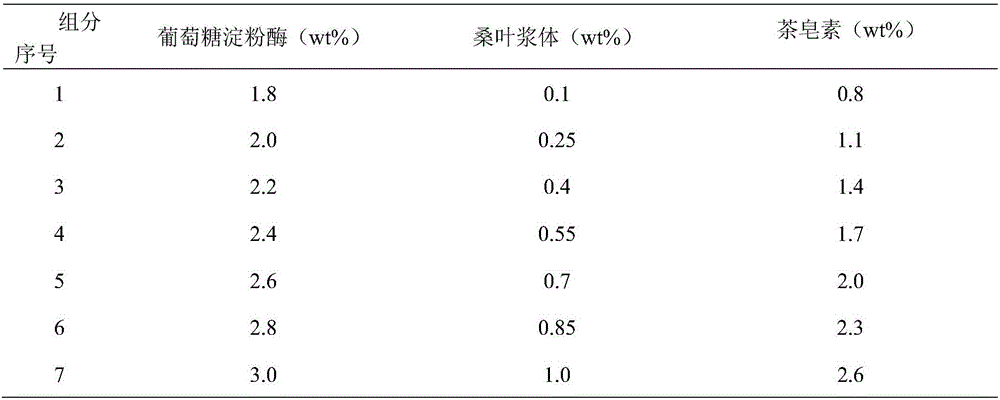

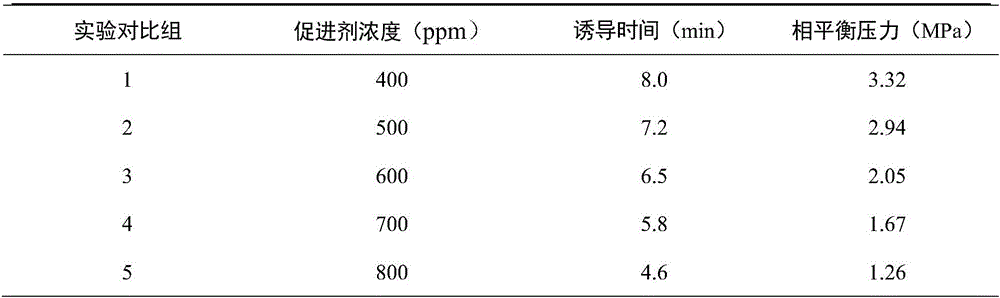

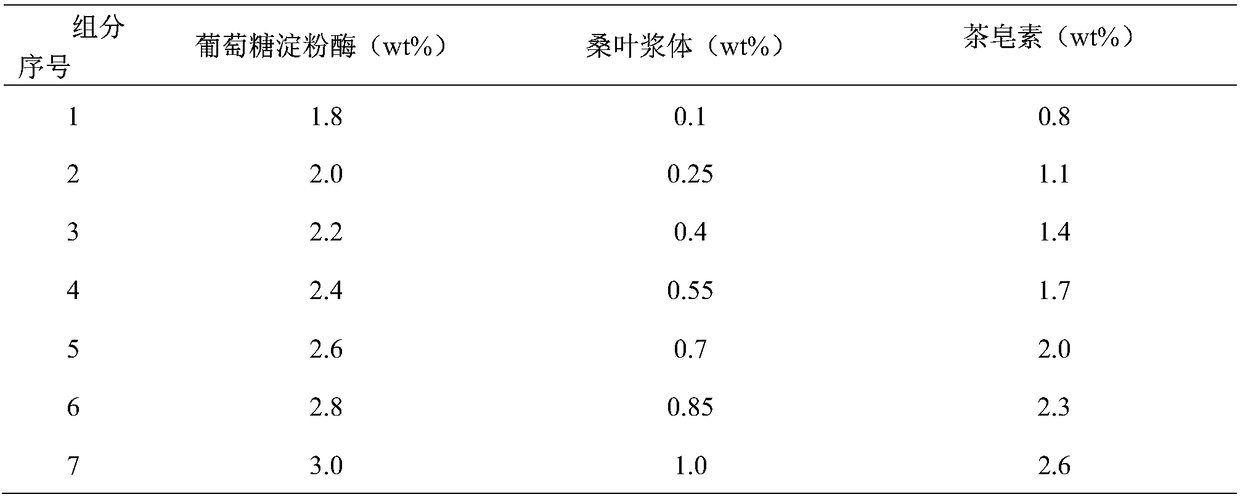

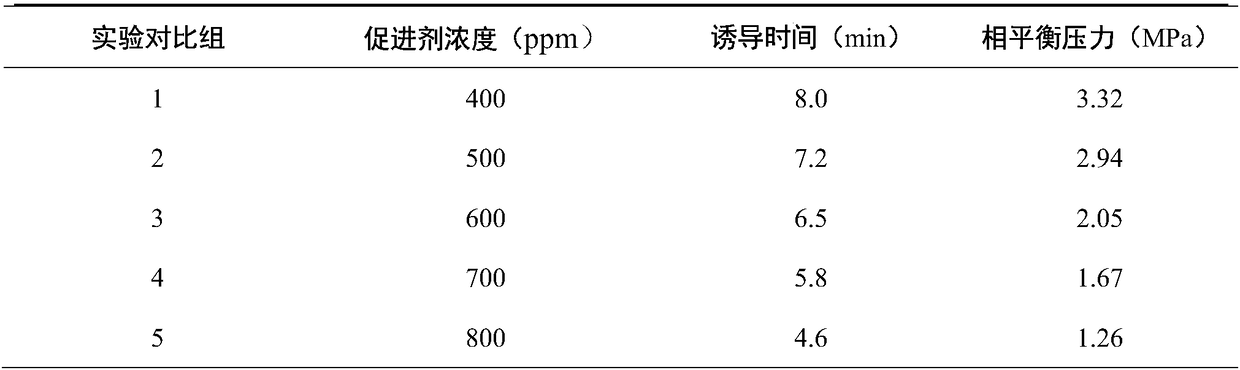

Gas hydrate accelerant and preparation method thereof

ActiveCN106543959AImprove economyNon-toxicOther chemical processesGaseous fuelsDistilled waterProduct gas

The invention relates to the technical field of natural gas hydrate production and utilization, in particular to a high-efficiency accelerant capable of strengthening natural gas hydrate formation and a preparation method thereof. The method includes: selecting dried mulberry leaves, performing grinding and sieving to obtain powder with a particle size of less than 0.3mm; mixing the mulberry leaf powder with distilled water according to a weight ratio of 1:15, conducting heating to 70DEG C, then performing stirring at a rotation speed of 800rpm for 10min to obtain a mulberry leaf slurry; weighing glucamylase, tea saponin, the mulberry leaf slurry and deionized water, conducting calculation by mass percentage content to prepare a mixed water solution with 1.8-3% of glucamylase, 0.8-2.6% of tea saponin and 0.1-1% of the mulberry leaf slurry; and heating the prepared mixed water solution to 40DEG C-50DEG C, and performing stirring in a stirring kettle for 60min so as to obtain the hydrate accelerant.

Owner:创科云涂节能新材料科技(苏州)有限公司

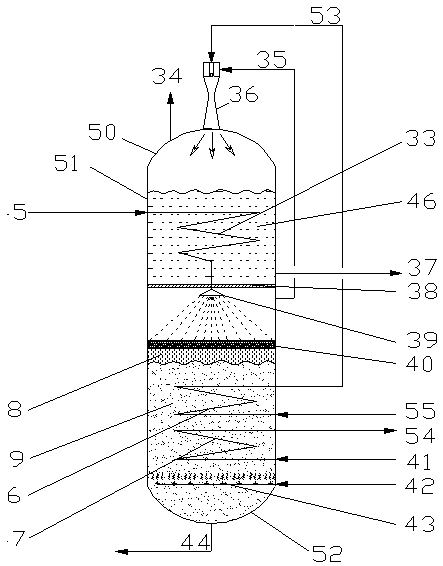

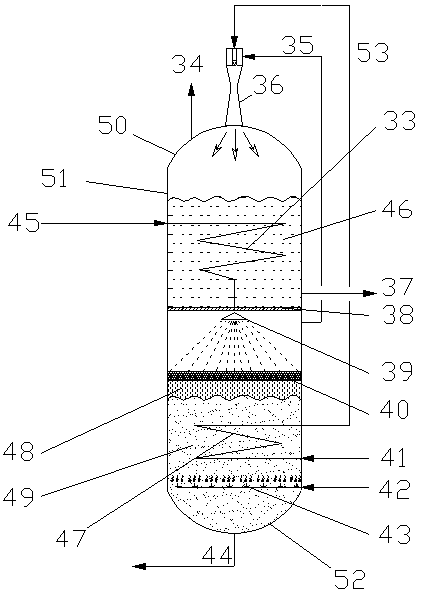

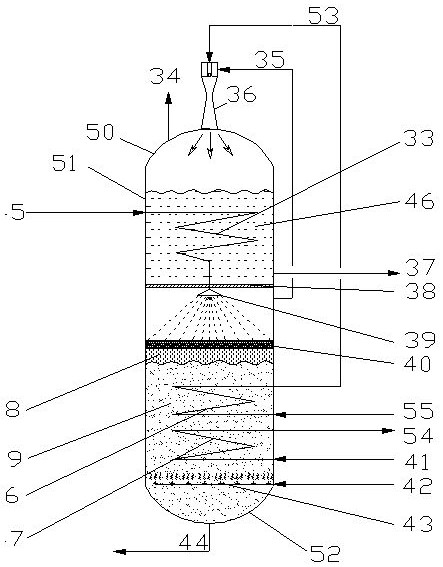

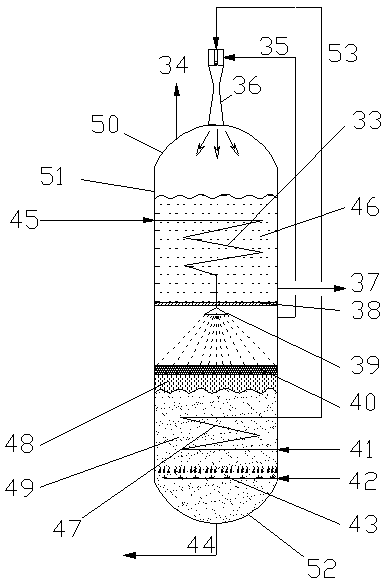

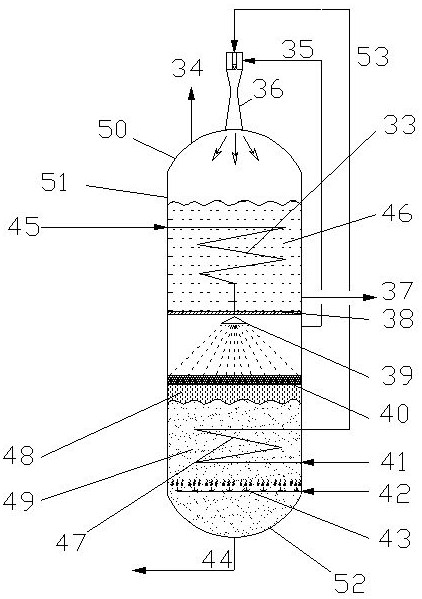

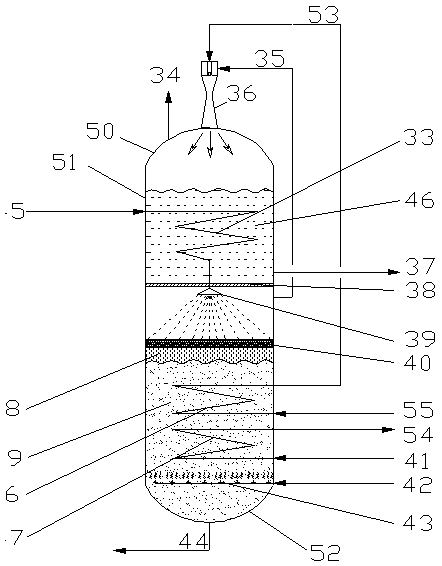

Process and device for separating acid gas by using hydration method

ActiveCN109420417AImprove liquidityTake advantage ofDispersed particle separationAlkali metal sulfides/polysulfidesWorking fluidGas phase

The invention discloses a process and a device for separating acid gases by using a hydration method. The device comprises a hydration reactor, a hydrate decomposer, an absorption reactor and a product tank; an acid gas feeding pipeline is connected with the gas-phase inlet of the hydration reactor, the liquid phase outlet of the hydration reactor is connected with the hydrate slurry inlet of thehydrate decomposer, and the cold-clear liquid outlet and the regenerated hydrate working fluid outlet of the hydrate decomposer are connected with the liquid-phase inlet of the hydrate reactor after passing through a cooler; the gas-phase outlet of the hydrate decomposer is connected with the gas-phase inlet of the absorption reactor, the gas phase outlet of the absorption reactor is connected with a purification gas outlet pipeline, and the liquid phase inlet of the absorption reactor is connected with an alkali liquor inlet pipeline. According to the invention, the energy in the whole process is fully utilized, heat absorption of hydrate decomposition and heat release of alkali method absorption are reasonably matched, and the energy consumption is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for treating gas containing carbon dioxide and hydrogen sulfide

ActiveCN108722148BGreat operating flexibilityMild operating conditionsGas treatmentDispersed particle separationHydration reactionChemical products

The invention discloses a treatment method and device for gas containing carbon dioxide and hydrogen sulfide. The device includes a hydration reactor, a hydrate decomposer, a gas exhaust processor, a primary absorption reactor, a secondary absorption reactor and a product tank . Also provided is a method for treating gas containing carbon dioxide and hydrogen sulfide by using the above device. It can produce NaHS products that meet the national quality standards while achieving acid gas discharge standards, and organically combine environmental governance with the production process of chemical products into an integrated process. Compared with the prior art, the method of the present invention can economically and efficiently pretreat the gas containing carbon dioxide and hydrogen sulfide, rationally utilize the energy in the process, and greatly reduce energy consumption; the whole process is environmentally friendly, reliable, No "three wastes" are generated.

Owner:CHINA PETROLEUM & CHEM CORP +1

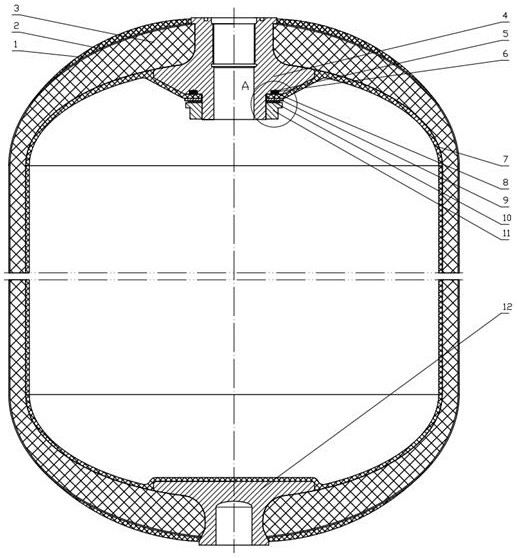

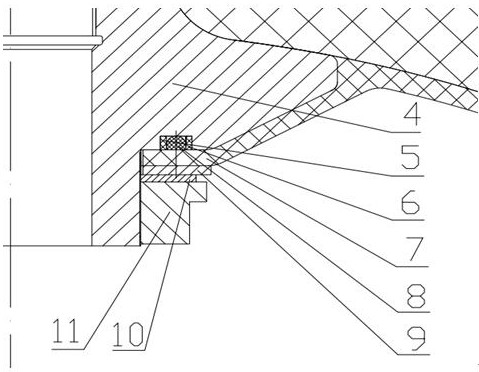

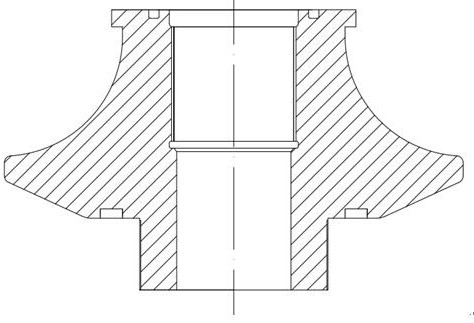

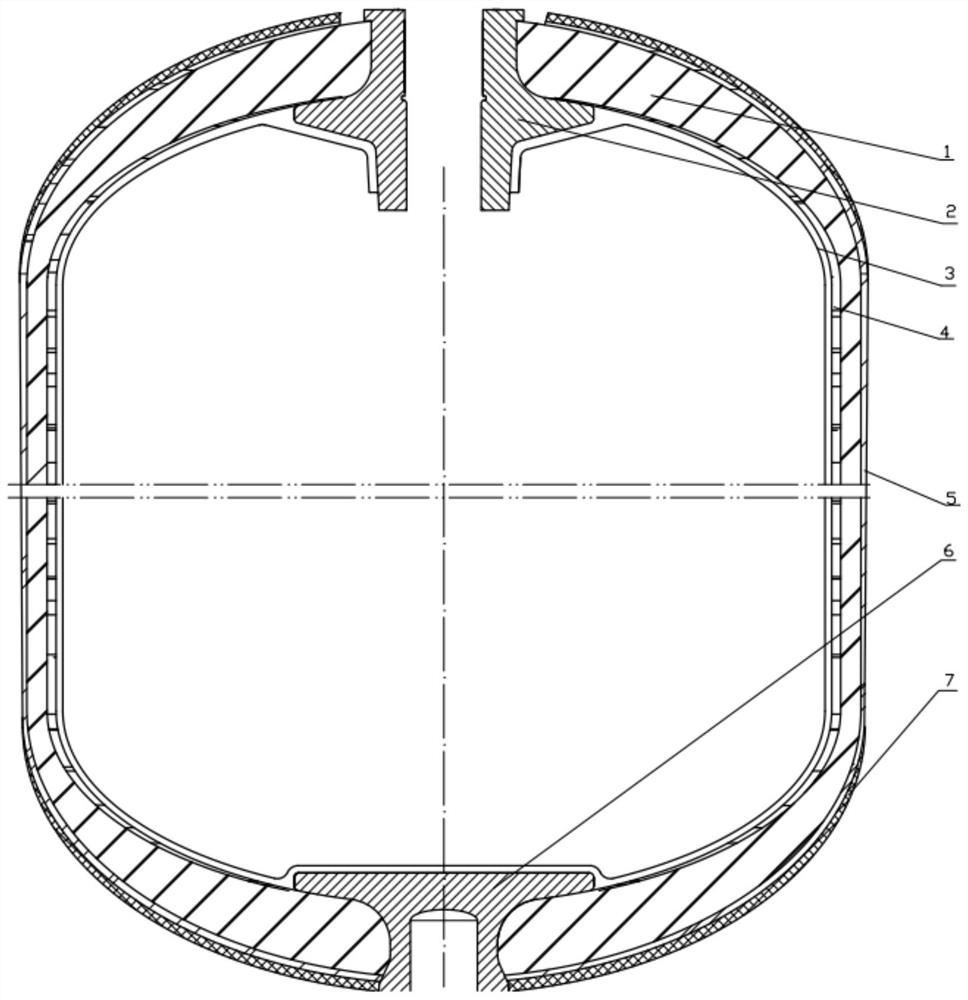

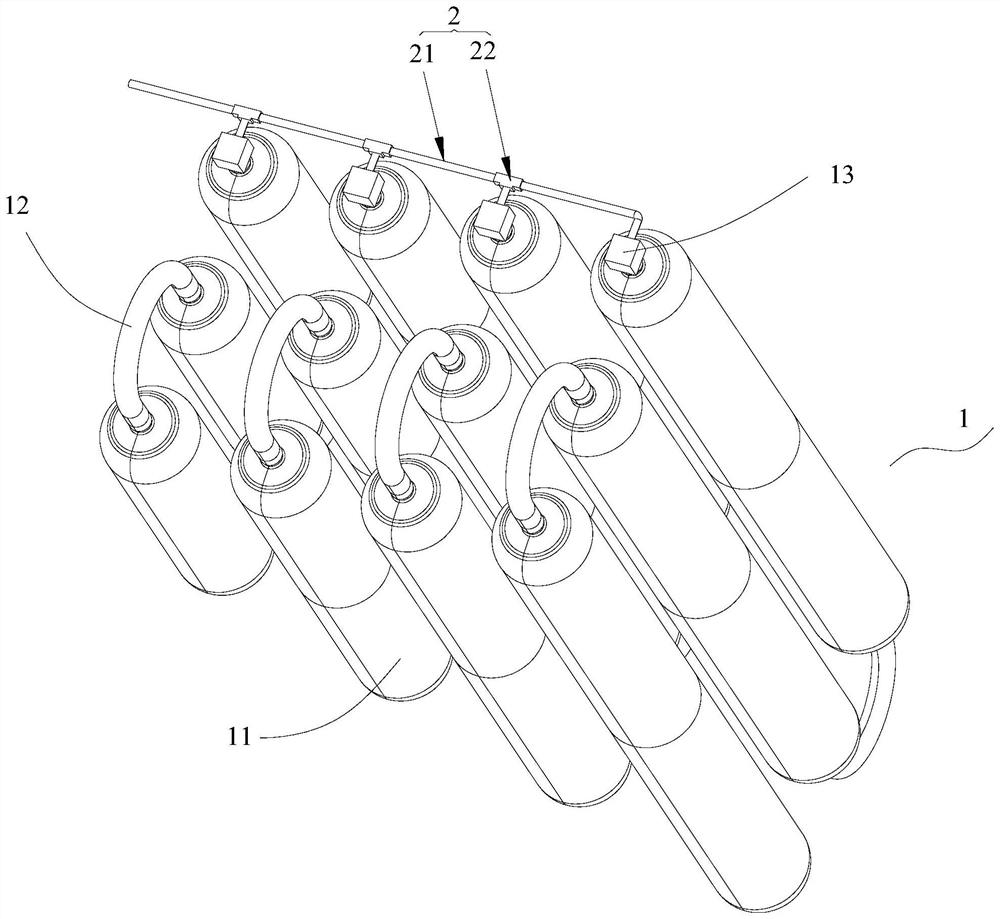

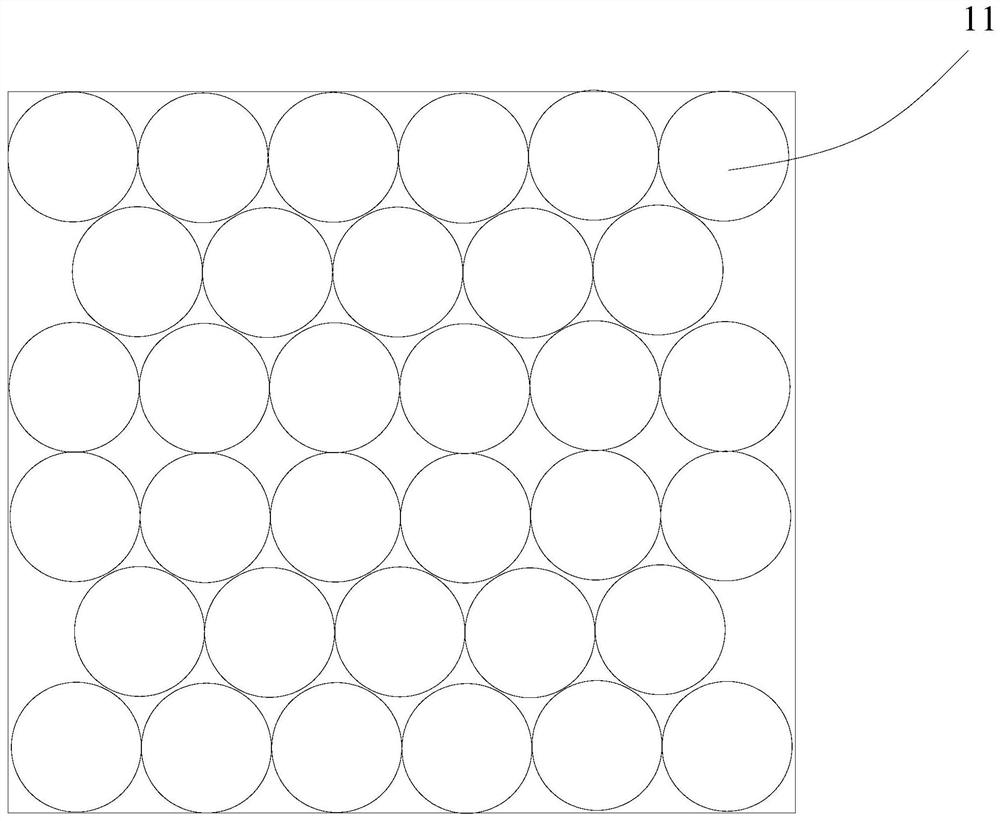

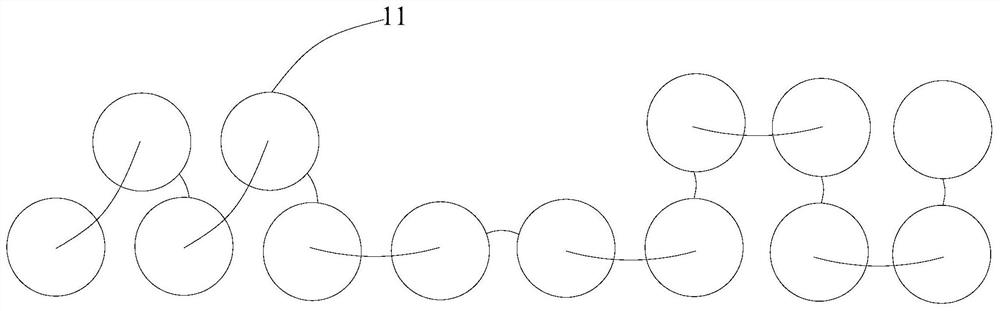

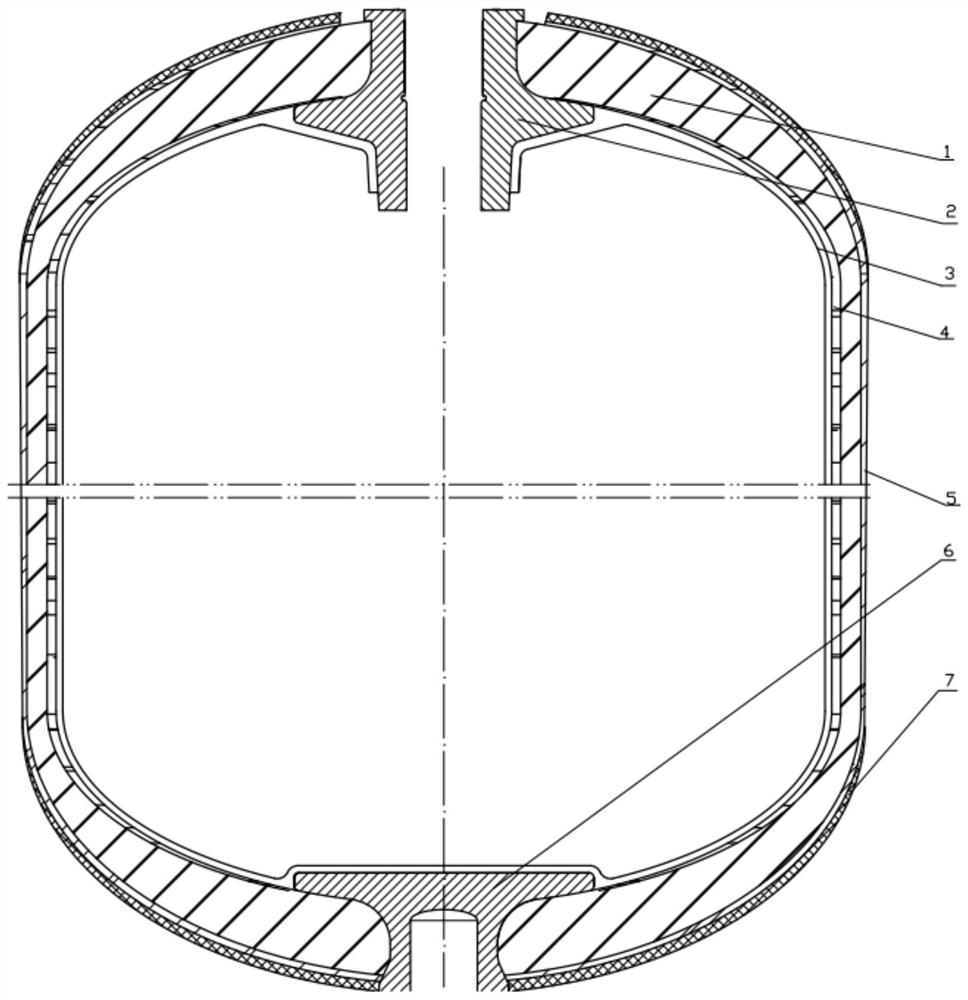

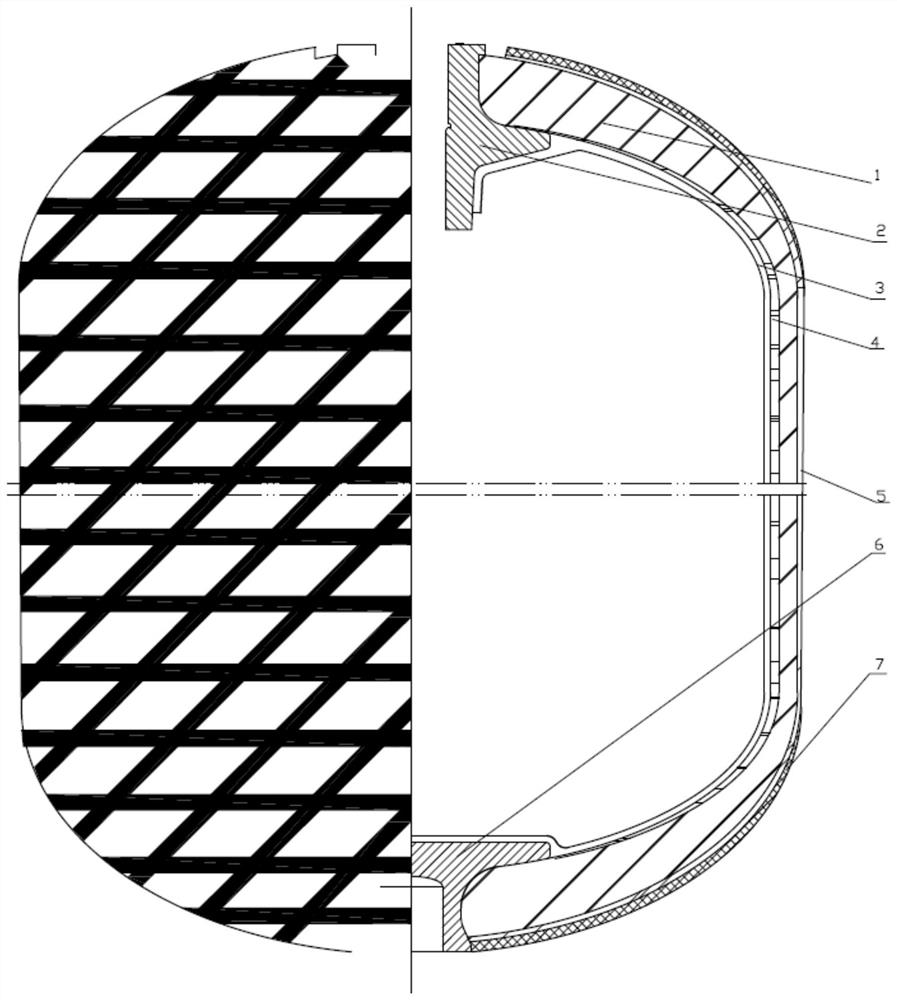

Plastic lining fiber reinforced composite material high-pressure hydrogen storage cylinder

PendingCN112228764ALight in massIncrease gas storage densityVessel mounting detailsVessel manufacturingAdhesive cementFiber-reinforced composite

The invention discloses a plastic lining fiber reinforced composite material high-pressure hydrogen storage cylinder comprising a plastic lining, a metal gas cylinder opening end and a metal gas cylinder tail end. The opening end of the plastic lining wrapped with a prestress fiber reinforced layer is bonded to the lower end face of the metal gas cylinder opening end through an adhesive, the lowerend of the plastic lining is attached to the metal gas cylinder tail end, and the fiber reinforced layer at the upper end of the gas cylinder is attached to the axial upper end face of the metal gascylinder opening end. The fiber reinforced layer at the lower end of the gas cylinder is attached to the axial lower end face of the metal gas cylinder tail end, a glass fiber protective layer is wound on the outer side of the fiber reinforced layer, and gas cylinder end socket anti-collision layers are arranged on the outer sides of end sockets at the two ends. An O-shaped ring and an anti-loosening gasket are arranged between the opening end of the plastic lining and the axial lower end face of the metal gas cylinder opening end and are pressed by a nut and a spring gasket. Triple sealing ofO-shaped ring sealing, gluing sealing and plastic lining self-tightening sealing is adopted, the higher the pressure in the gas cylinder is, the tighter the pressure between the plastic lining and the metal gas cylinder opening end is, and gas leakage is more difficult.

Owner:ZHEJIANG UNIV

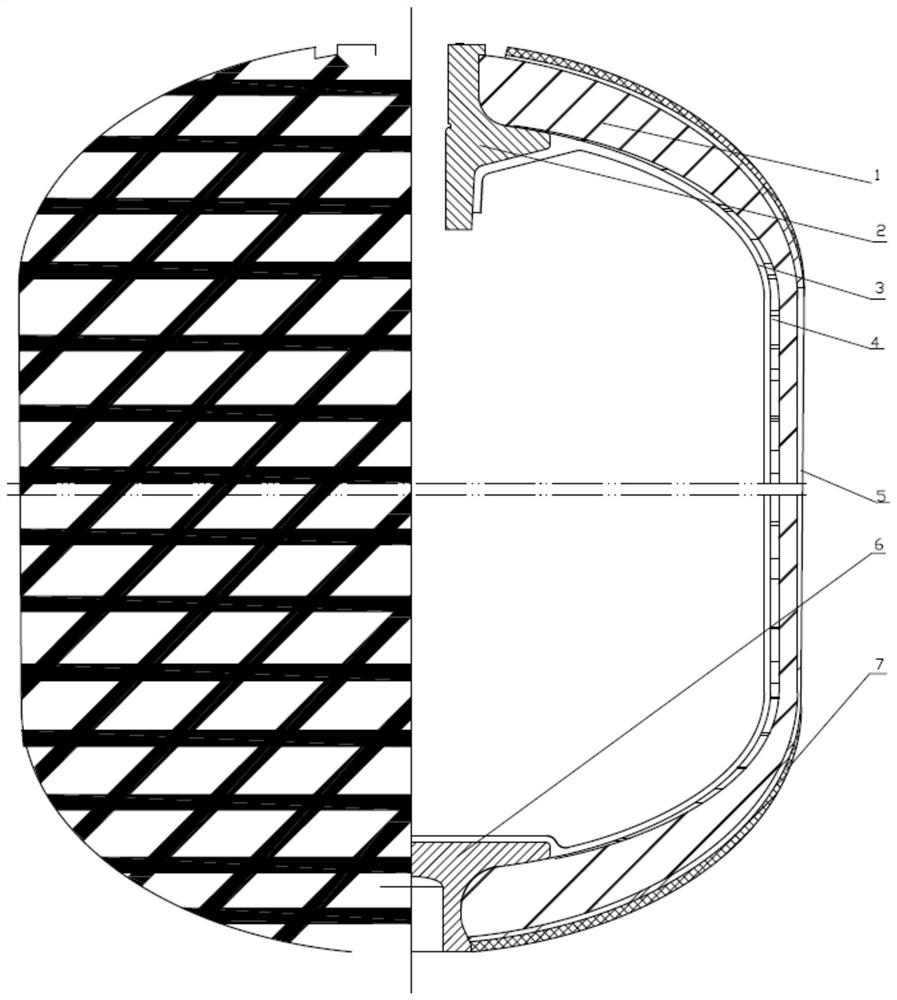

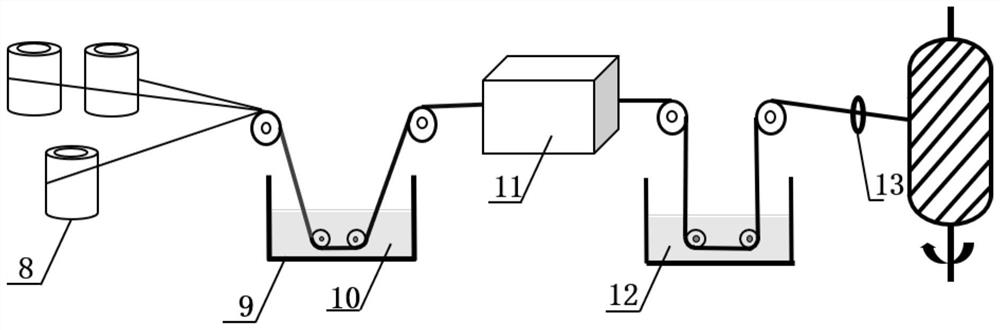

Non-Newtonian fluid impregnated grid enhanced hydrogen storage pressure vessel structure and process

ActiveCN112344200AImprove impact resistanceImprove structural stabilityVessel mounting detailsVessel manufacturingGas cylinderResin matrix

The invention discloses a non-Newtonian fluid impregnated grid enhanced hydrogen storage pressure vessel structure and process. The pressure vessel structure comprises a fiber reinforced resin matrixcomposite material, a grid structure reinforcing layer, a fiber protective layer and anti-collision materials arranged at end sockets at the two ends which are sequentially arranged on the outer sidesurfaces of a gas cylinder lining, an open end and a tail end of a metal gas cylinder outwards in a prestress winding mode, wherein the whole gas cylinder container structure is reinforced through thegrid structure reinforcing layer, fibers used for forming the grid structure reinforcing layer are impregnated with non-Newtonian fluid, gum dipping winding forming is carried out after drying treatment, soft grid structure molds at a cylinder body and two ends of the end sockets are molded and manufactured by utilizing a casting molding method, then adhering the soft grid structure molds to theouter surface of a gas cylinder wound with a fiber reinforced resin matrix composite material in a common adhering manner, and then molding a grid structure reinforcing layer. The prepared hydrogen storage pressure vessel has the characteristics of high rigidity, impact resistance, light weight and low cost.

Owner:ZHEJIANG UNIV

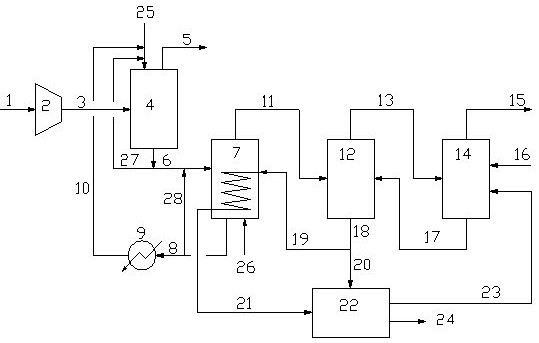

Combined treatment process and system for acid gas

ActiveCN108722135AGreat operating flexibilityMild operating conditionsGas treatmentDispersed particle separationProduct gasChemical products

The invention discloses a combined treatment process and a system for acid gas. According to the combined treatment process and the system, NaHS products meeting national quality standards can be produced while up-to-standard discharge of the acid gas is realized; environmental improvement is organically combined with the production process of a chemical product. Compared with the prior art, the process and the system disclosed by the invention have the advantages that the acid gases containing CO2 and hydrogen sulfide can be economically and efficiently pretreated, energy in the technologicalprocess is reasonably utilized and energy consumption is greatly reduced; the whole treatment process is environmentally friendly and reliable and no three wastes are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing gas hydrate accelerant

The invention provides a method for preparing gas hydrate accelerant, which takes a high pressure gas cylinder as gas source; the high pressure gas cylinder is regulated to have proper pressure by a pressure regulating valve, and the consumed natural gas is calculated by a mass flowmeter; the temperature and the pressure in a reactor are monitored by a pressure and temperature transmitter; thermostatic waterbath is used for controlling the temperature of the liquid in a trough, thus regulating the temperature in the reactor; a data acquisition system and a computer are used for collecting data, and an opto-electrical lens is used for monitoring the forming situation of hydrate in the reactor. The composite accelerant is low in cost and little in dosage, ensures the generating condition ofthe hydrate to be reduced, the time to be shortened and the gas storage quantity to be increased, and effectively improves the economic benefit of the production of the hydrate.

Owner:溧阳常大技术转移中心有限公司

Treatment method and device for acid gas

ActiveCN108722149AReasonable useReduce energy consumptionDispersed particle separationSulfur compoundsChemistryPre treatment

The invention discloses a treatment method and a device for acid gas. The device comprises a hydration reactor, a hydrate neutralizing device, a first-stage absorption reactor, a second-stage absorption reactor and a product tank. The invention also provides a method for treating the acid gas by adopting the device. According to the treatment method and the device, NaHS products meeting national quality standards can be produced while up-to-standard discharge of the acid gas is realized; environmental improvement is organically combined with the production process of a chemical product. Compared with the prior art, the method disclosed by the invention has the advantages that the acid gases containing CO2 and hydrogen sulfide can be economically and efficiently pretreated, energy in the technological process is reasonably utilized and energy consumption is greatly reduced; the whole treatment process is environmentally friendly and reliable and no three wastes are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Power module, carrier and safety management method of power module

PendingCN113757551ALower requirementImprove space utilizationVessel mounting detailsVessel geometry/arrangement/sizeFiberMechanical engineering

The invention relates to the technical field of gas storage containers, and provides a power module, a carrier and a safety management method of the power module. The power module comprises at least one gas storage cylinder group. Each gas storage cylinder group comprises gas storage cylinders and a connecting assembly, wherein the gas storage cylinder group is provided with at least two gas storage cylinders. The gas storage cylindersin each gas storage cylinder group communicate with one another through the connecting assemblies, and the gas storage cylinder groups and / or the gas storage cylinders are arranged and combined according to a preset mode. The carrier comprises a carrier body and the power module. Compared with the prior art, the power module and the carrier with the power module have the advantages that by reducing the diameter of each single gas storage cylinder element and matching the configuration mode of the space in a passenger car, the requirement of the gas storage cylinders for the structural design of a car body is greatly reduced, and the space utilization rate is increased; and the design and forming process difficulty of a fiber laying layer can be reduced, the use amount of the carbon fibers can be reduced to a certain extent, and the gas storage density of the gas storage cylinders is reduced.

Owner:SHENZHEN XIWAN TECH CO LTD

Treating technology and system for hydrogen sulfide and dioxide carbon containing acidic gas

ActiveCN108722138ACost-effective pretreatmentReasonable useDispersed particle separationEnvironmental resistanceChemical products

The invention discloses a treating technology and system for hydrogen sulfide and dioxide carbon containing acidic gas. With the adoption of the technology and the system, NaHS products meeting national quality standard can be produced while acidic gas standardized discharging is realized; the environment treatment and the production process of chemical products are integrated. Compared with the prior art, the CO2 gas and hydrogen sulfide containing acidic gas can be economically and efficiently pretreated; the energy in the technical process can be reasonably utilized, so that the energy consumption is extremely decreased; the whole treatment process is environmentally friendly, reliable, and free of three wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrate promoter and preparation method thereof

ActiveCN104857891BLower spawn conditionsReduce build timeOther chemical processesTransportation and packagingWater desalinationSeparation technology

The invention belongs to the technical field of gas hydrate production promotion and utilization, and in particular relates to a hydrate accelerator and a preparation method thereof. said Hydration Promoter, It is prepared by stirring cocamidopropyl betaine, dimethylsiloxane, non-ionic fluorosurfactant and deionized water at 65~85℃ for 30~40 minutes; among them, cocamidopropyl The mass percentage of betaine in the solvent is 3-7%; the mass percentage of dimethylsiloxane in the solvent is 1.2-4.5%; the mass percentage of non-ionic fluorosurfactant in the solvent is 0.2- 1.5%, and the rest is deionized water. The hydrate accelerator of the present invention can be widely used in the fields of gas hydrate storage and transportation technology, gas hydrate separation technology, and seawater desalination; and the cost is low, the dosage is small, the conditions for hydrate formation are reduced, the time is shortened, and the gas storage capacity is reduced. The increase effectively improves the economic benefits of hydrate production.

Owner:邳州市博睿投资管理有限公司

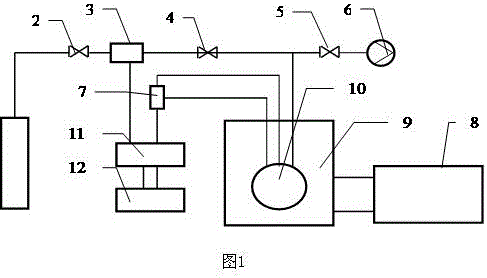

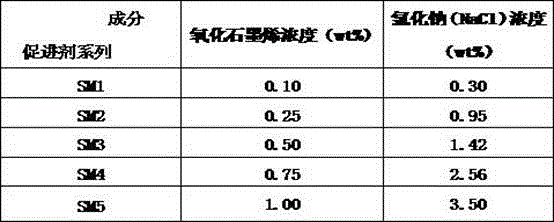

Graphene oxide gas hydrate accelerator and preparation method thereof

ActiveCN104888673BReduce build timeIncrease gas storage densityPressurized chemical processGaseous fuelsDistilled waterEconomic benefits

Owner:泉州职业技术大学

A method and device for treating acid gas

ActiveCN108722139BGreat operating flexibilityMild operating conditionsGas treatmentDispersed particle separationChemical productsProcess engineering

The invention provides a method and device for treating acid gas. The device can produce NaHS products meeting national quality standards while realizing up-to-standard discharge of the acid gas, andorganically integrates environmental governance and the production process of chemical products into an integrated process. Compared with the prior art, the method has the advantages that the acid containing CO2 gas and hydrogen sulfide gas can be economically and efficiently pretreated, energy during a technical process is reasonably utilized, energy consumption is greatly reduced, and the wholetreatment process is environmentally friendly, reliable, and free from production of three wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrate Accelerator and Its Application in Preparation of High Gas Storage Density Gas Hydrate

ActiveCN104974713BNon-toxicNo pollution in the processOther chemical processesGaseous fuelsVolumetric Mass DensityHigh pressure

The invention belongs to the technical field of energy materials, and discloses a hydrate accelerator and its application in the preparation of gas hydrate with high gas storage density. The accelerator includes amino acid and water; it is formed by uniformly mixing 100 parts by mass of water and 0.05-5 parts by mass of amino acid. Said application is specifically mixing 100 parts by mass of water and 0.05 to 5 parts by mass of amino acid to obtain an aqueous accelerator solution; placing the aqueous accelerator solution in a high-pressure reactor, feeding high-pressure gas at a low temperature, and reacting for a period of time , to obtain solid gas hydrates with high gas storage density. The accelerator of the present invention is green and environmentally friendly; it can shorten the hydration induction time, increase the gas storage capacity, and increase the gas storage density; at the same time, the accelerator of the present invention is cheap, small in dosage, wide in source, recyclable and reusable, and has no effect on temperature and pressure conditions. There is no special requirement; the method for preparing the gas hydrate with high gas storage density is fast, efficient, simple and easy to realize.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing composite hydrate accelerant

Owner:溧阳常大技术转移中心有限公司

A kind of acid gas combined treatment process and system

ActiveCN108722135BGreat operating flexibilityMild operating conditionsGas treatmentDispersed particle separationEngineeringChemical products

The invention discloses a combined treatment process and a system for acid gas. According to the combined treatment process and the system, NaHS products meeting national quality standards can be produced while up-to-standard discharge of the acid gas is realized; environmental improvement is organically combined with the production process of a chemical product. Compared with the prior art, the process and the system disclosed by the invention have the advantages that the acid gases containing CO2 and hydrogen sulfide can be economically and efficiently pretreated, energy in the technologicalprocess is reasonably utilized and energy consumption is greatly reduced; the whole treatment process is environmentally friendly and reliable and no three wastes are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of gas hydrate promoter and preparation method thereof

ActiveCN106543959BImprove economyNon-toxicOther chemical processesGaseous fuelsDistilled waterProduct gas

Owner:创科云涂节能新材料科技(苏州)有限公司

Structure and process of grid-reinforced hydrogen storage pressure vessel impregnated with non-Newtonian fluid

ActiveCN112344200BImprove impact resistanceImprove structural stabilityVessel mounting detailsVessel manufacturingGas cylinderResin matrix

The invention discloses a non-Newtonian fluid impregnated grid reinforced hydrogen storage pressure vessel structure and technology. It includes fiber-reinforced resin-based composite materials that are prestressed and wound on the inner liner of the gas cylinder, the open end of the metal gas cylinder and the outer surface of the tail end, the reinforcement layer of the grid structure, the fiber protection layer and the anti-corrosion protection at the two ends of the head. The entire structure of the gas cylinder container is reinforced with a grid structure reinforcement layer, and the fibers used in the formation of the grid structure reinforcement layer are impregnated with non-Newtonian fluid, dried and then impregnated and wound; firstly, the casting method is used The soft grid structure molds for the cylinder body and the two ends of the head are molded separately, and then bonded to the outer surface of the gas cylinder after winding the fiber reinforced resin-based composite material by joint bonding, and then the grid structure reinforcement layer is formed. The hydrogen storage pressure vessel prepared by the invention has the characteristics of high rigidity, impact resistance, light weight and low cost.

Owner:ZHEJIANG UNIV

Traditional Chinese herbal medicine composition, and preparation method and application thereof

ActiveCN110448997AReduce formation induction timeIncrease the rate of formationDispersed particle separationAir quality improvementFormation rateCarbon dioxide

The invention belongs to the technical field of carbon capturing and seal storage, and specifically relates to a traditional Chinese herbal medicine composition, and a preparation method and an application thereof. According to the invention, the traditional Chinese herbal medicine composition is prepared by selecting traditional Chinese herbal medicines namely Radix Wikstroemiae Indicae, Radix Ilicis Asprellae, Rhizoma Dioscoreae Tokoro, Radix Rhodomyrti, Radix Helicteris, common cnidium fruit, fig and Abrus cantoniensis Hance as raw materials. The traditional Chinese herbal medicine composition provided by the invention can promote rapid generation of carbon dioxide hydrate, solves the problems of slow formation rate, insufficient gas storage amount, long induction time and the like in the use process of a hydrate technology, realizes capturing and seal storage of carbon dioxide by utilizing the hydrate technology at the same time, reduces the content of the carbon dioxide in atmosphere, thereby controlling the trend of global warming.

Owner:SOUTH CHINA UNIV OF TECH

A kind of gas hydrate promoter and preparation method thereof

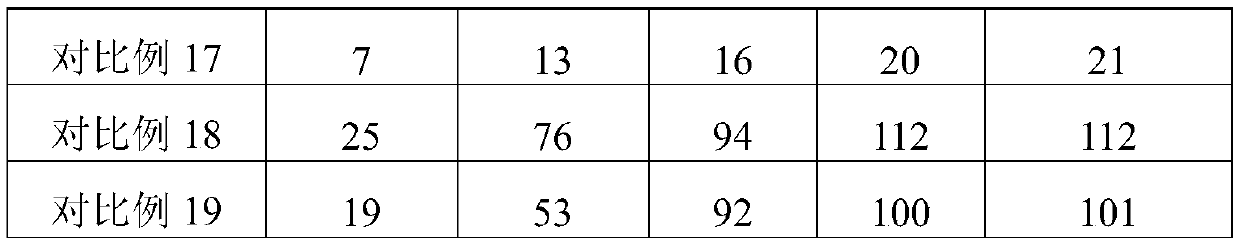

ActiveCN104667844BLower spawn conditionsReduce build timePressurized chemical processGaseous fuelsEngineeringDioxyethylene Ether

The invention belongs to the technical field of gas hydrate production and utilization, and in particular relates to a gas hydrate accelerator and a preparation method thereof. The gas hydrate accelerator is made by mixing coconut oil fatty acid diethanolamide, polyoxyethylene ether sulfate, and polyquaternium salt as additives with deionized water at 72-83°C for 120 minutes; the coconut oil fatty acid Diethanolamide accounts for 1-2.5% by mass of the solvent; polyoxyethylene ether sulfate accounts for 9-16% by mass of the solvent; polyquaternium salt accounts for 0.2-0.5% by mass of the solvent %, and the rest is deionized water. The gas hydrate promoter of the invention has the advantages of good hydrate formation promoting effect, wide application, low cost and good economic benefits.

Owner:江苏溢坤医疗科技有限公司

An acid gas treatment process and system

ActiveCN108722140BGreat operating flexibilityMild operating conditionsDispersed particle separationChemical productsProcess engineering

The invention discloses an acid gas treatment process and system, which can produce NaHS products meeting the national quality standards while realizing acid gas discharge up to the standard, and organically combine environmental treatment and chemical product production processes into an integrated process. Compared with the prior art, the process and system of the present invention can cost-effectively treat CO-containing 2 The acid gas of gas and hydrogen sulfide gas is pretreated, and the energy in the process is rationally utilized, which greatly reduces energy consumption; the entire treatment process is environmentally friendly, reliable, and produces no "three wastes".

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for treating acid gas

ActiveCN108722139AGreat operating flexibilityMild operating conditionsGas treatmentDispersed particle separationEnvironmental resistanceProduct gas

The invention provides a method and device for treating acid gas. The device can produce NaHS products meeting national quality standards while realizing up-to-standard discharge of the acid gas, andorganically integrates environmental governance and the production process of chemical products into an integrated process. Compared with the prior art, the method has the advantages that the acid containing CO2 gas and hydrogen sulfide gas can be economically and efficiently pretreated, energy during a technical process is reasonably utilized, energy consumption is greatly reduced, and the wholetreatment process is environmentally friendly, reliable, and free from production of three wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method and device for treating acid gas

ActiveCN108722149BGreat operating flexibilityMild operating conditionsSulfur compoundsDispersed particle separationHydration reactionProcess engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment process and system for acid gas

ActiveCN108722140AReasonable useReduce energy consumptionDispersed particle separationChemical productsProduct gas

The invention discloses a treatment process and a system for acid gas. According to the treatment process and the system, NaHS products meeting national quality standards can be produced while up-to-standard discharge of the acid gas is realized; environmental improvement is organically combined with the production process of a chemical product. Compared with the prior art, the process and the system disclosed by the invention have the advantages that the acid gases containing CO2 and hydrogen sulfide can be economically and efficiently pretreated, energy in the technological process is reasonably utilized and energy consumption is greatly reduced; the whole treatment process is environmentally friendly and reliable and no three wastes are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com