Process and device for separating acid gas by using hydration method

A sour gas and hydration technology, applied in separation methods, dispersed particle separation, sulfur compounds, etc., can solve the problems of increased energy consumption, complex production equipment, poor fluidity of hydrates, etc., to ensure that the equipment and treatment process are environmentally friendly and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

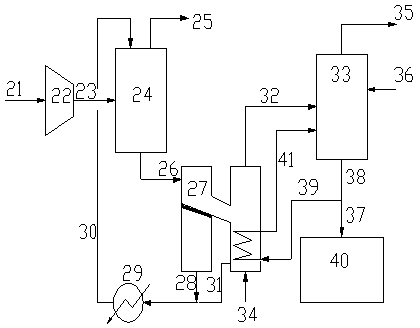

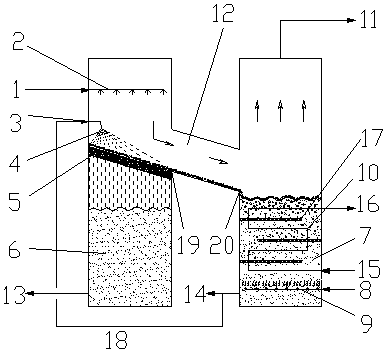

[0074] Acid gas volume Q=400Nm in a refinery 3 / h, pressure 0.7Mpa, where H 2 S volume fraction is 84%, CO 2 The volume fraction is 16%, and the remainder is hydrocarbons and other substances. use figure 1 The shown processing method and device process acid gas. Among them, the hydrate decomposer adopts figure 2 The structure of the resolver.

[0075] The operating conditions and treatment effects during the treatment process are as follows: the acid gas 21 is pressurized by the compressor 22 to 1.2Mpa and then introduced into the hydration reactor 24, where it reacts with the hydrate working fluid in the hydration reactor 24. The reaction conditions are: pressure 1.2 Mpa, temperature 5°C, hydrate working fluid consists of water, SDS accounting for 0.03% of the mass fraction of the aqueous solution, polyethylene glycol accounting for 10% of the aqueous solution, diesel oil with a volume ratio of 1 / 4 to water, and a molar ratio of water to water of 0.8% Span (sorbitan f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com