A kind of gas hydrate promoter and preparation method thereof

A hydrate accelerator and accelerator technology, which are applied in the methods of chemically changing substances by atmospheric pressure, gas fuels, chemical instruments and methods, etc., can solve the problem of low gas content, slow formation rate, long induction time, etc. problems, to achieve the effects of improving economic efficiency, increasing gas storage, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

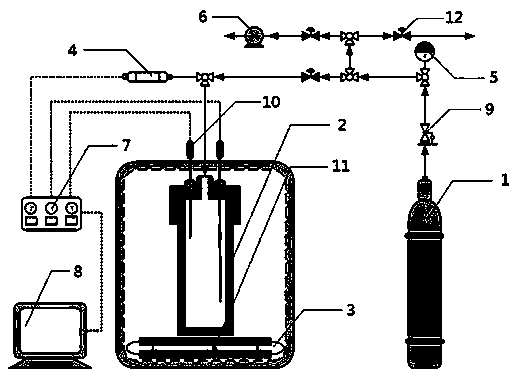

Method used

Image

Examples

Embodiment 1

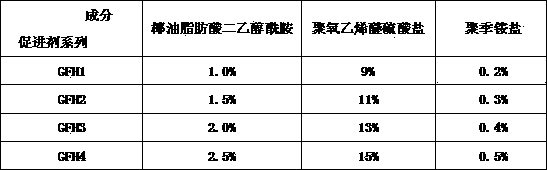

[0037] The selected composite accelerator consists of: coconut oil fatty acid diethanolamide with a mass percentage of 1-2.5%; polyoxyethylene ether sulfate with a mass percentage of 9-15%; and a mass percentage of 0.2- 0.5% polyquaternium. The experimental steps are the same as above. The equilibrium condition of hydrate formation is that the temperature is 1.9~5.5℃ and the pressure is 0.79~2.7Mpa.

[0038] Example 1:

[0039] The selected accelerator GFH1 is composed of the following components: 1% by mass of coconut oil fatty acid diethanolamide, 9% by mass of polyoxyethylene ether sulfate, 0.2% by mass of polyoxyethylene ether sulfate quaternary ammonium salt. Add deionized water and stir at 72°C for 120 min to prepare a hydrate accelerator. The experiment was done with methane gas at a temperature of 5.6°C, and the experimental procedure was the same as above. The experimental results are shown in Table 2.

[0040] Experiment number Mass concentration ...

Embodiment 2

[0042] The selected accelerator GFH4 is composed of the following components: coconut oil fatty acid diethanolamide with a mass percentage of 2.5%, polyoxyethylene ether sulfate with a mass percentage of 15%, polyoxyethylene ether sulfate with a mass percentage of 0.5%. quaternary ammonium salt. Add deionized water and stir at 83°C for 120 min to prepare a hydrate accelerator. Experiment with methane gas at a temperature of 5.7°C, and the experimental procedure is the same as above. The experimental results are shown in Table 3.

[0043] Experiment number Mass concentration (wt%) Induction time (min) Phase equilibrium pressure (MPa) 1 0.1 8.9 2.98 2 0.2 7.8 2.87 3 0.3 6.1 2.45 4 0.4 4.6 2.16 5 0.5 3.3 2.12 6 0.6 3.1 2.12

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com