Method for detecting mercury content in vinyl chloride monomer

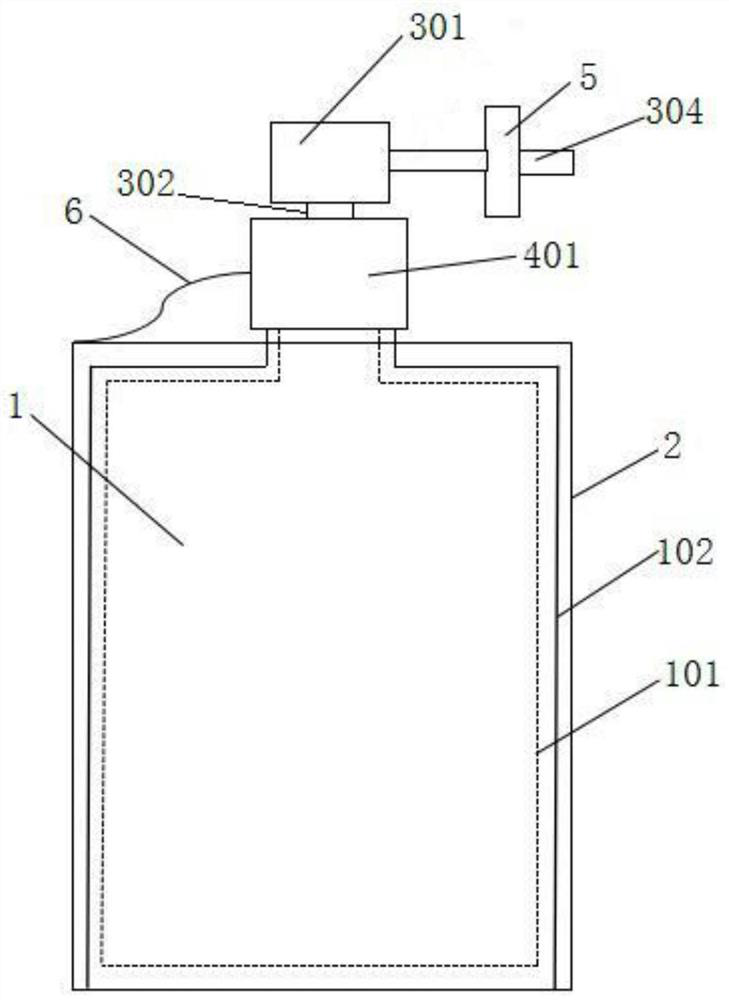

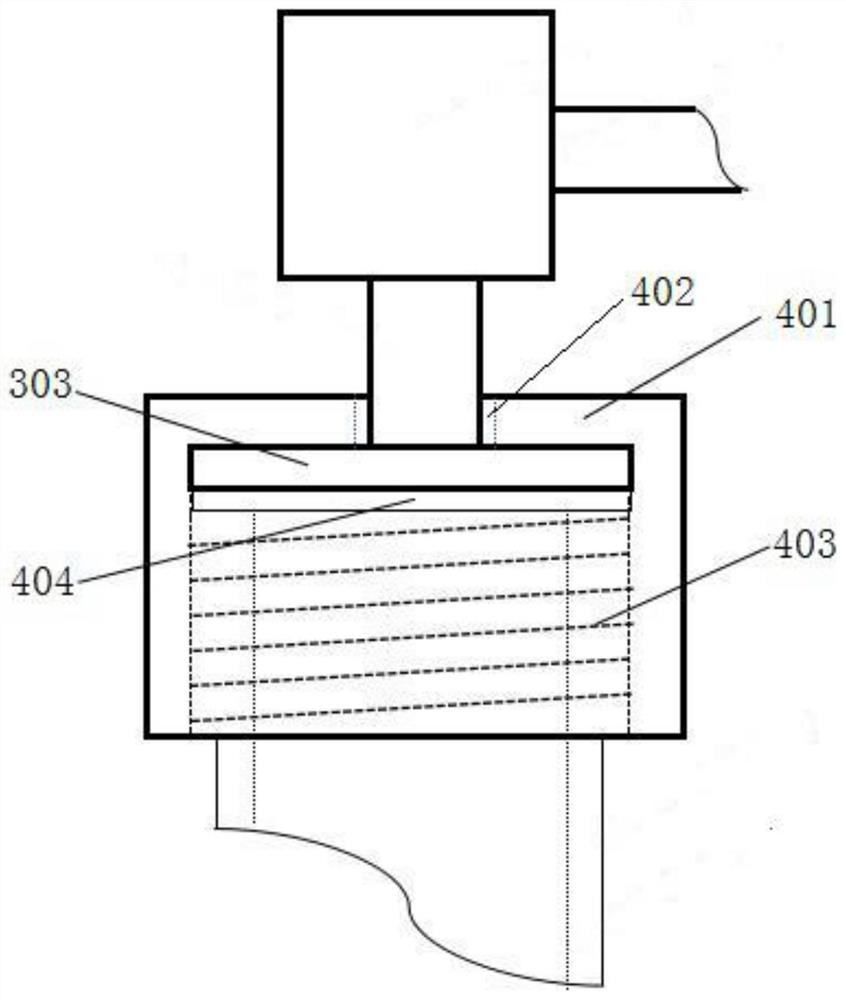

A technology of vinyl chloride monomer and content, which is applied in the direction of measuring device, test sample preparation, color/spectral characteristic measurement, etc. It can solve the problem of difficult to accurately measure the sampling amount of vinyl chloride monomer, difficult to observe the appearance of the sample, the sampling amount of the sample, Threatening the safety and health of personnel and other issues, to achieve the effect of preventing insufficient sampling volume, facilitating accuracy, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

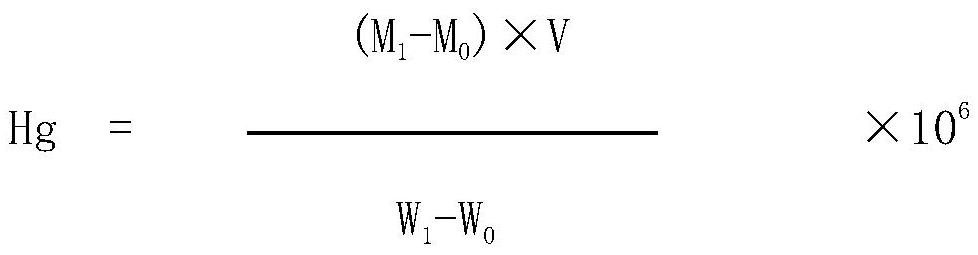

[0068] Utilize above-mentioned vinyl chloride monomer sampling device to detect the mercury content in the vinyl chloride monomer of acetylene method, specifically comprise the following steps:

[0069] S1. In the pressure-resistant thick-walled quartz glass sample bottle of the vinyl chloride monomer sampling device with a capacity of 600ml, put a cleaned magnetic stirrer and 50ml of oxidizing acidic mixed solution, and the oxidizing acidic In the mixed solution, the mass concentration of sodium chloride is 0.5%, the mass concentration of sulfuric acid is 5%, and the mass concentration of potassium dichromate is 0.05%. Tighten the bottle cap of the sample bottle, and weigh the total mass of the vinyl chloride monomer sampling device currently described as W 0 .

[0070] S2. Use the vinyl chloride monomer sampling device to collect about 350 ml of liquid vinyl chloride monomer samples. After sampling, close the sample valve and then disconnect the connection. Weigh the total ...

Embodiment 2

[0096] This embodiment is a control experiment of embodiment one. According to the same steps and detection conditions as in embodiment one, the A#, B#, C# vinyl chloride monomer samples of Yibin Haifeng Herui Co., Ltd. are repeatedly sampled and tested, which is consistent with the implementation Example 1 differs only in:

[0097] (1) In step S1, instead of adding an oxidizing acidic mixed solution, 50 ml of ultrapure water was added.

[0098] (2) The blank control group in step S4 is 100 ml of ultrapure water.

[0099] The detection result of this embodiment is compared with embodiment 1, and the results are shown in Table 3.

[0100] Table 3 embodiment one and embodiment two detection result contrast

[0101]

[0102] As can be seen from Table 3, for the detection of 3 batches of samples, the average value of the detection results of embodiment two is significantly less than the average value of the detection results of embodiment one, indicating that there may be mer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com