Elastic annular electrode for reducing grounding resistance and manufacturing method thereof

A ring-shaped electrode and grounding resistance technology, applied in the field of geophysical exploration, can solve the problems of large impact on the surrounding environment, cumbersome construction, and difficulty in meeting the needs of actual construction, and achieve the effect of increasing the contact area and reducing the grounding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

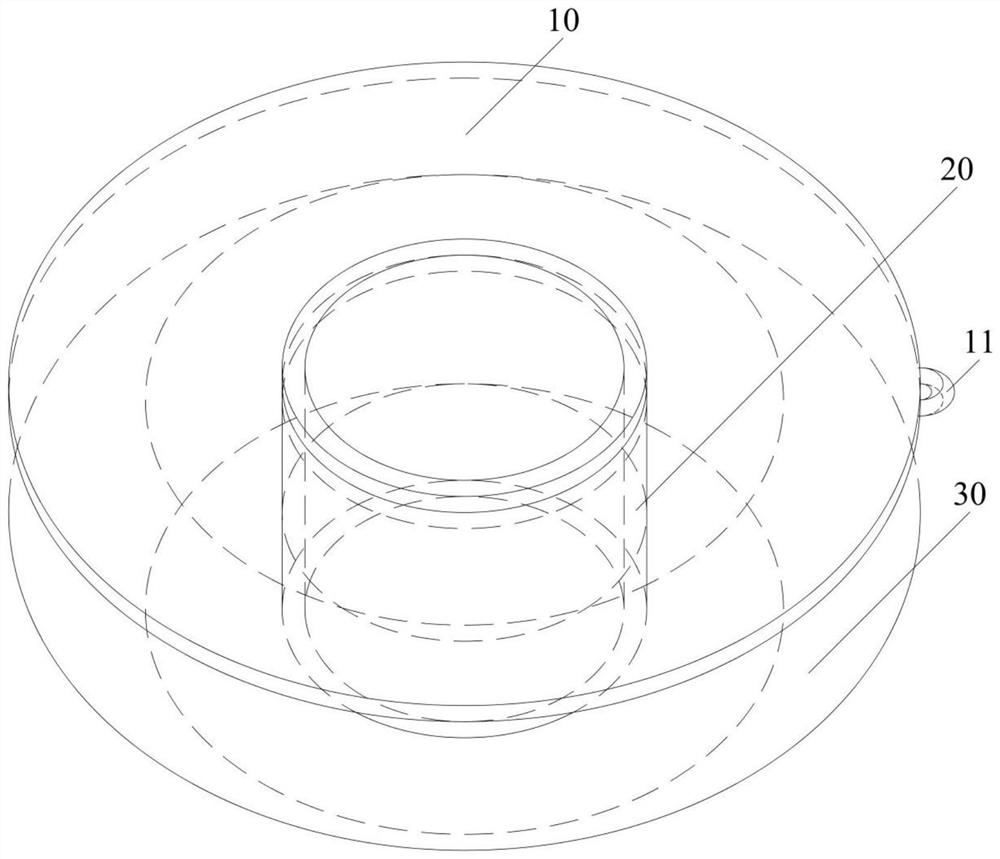

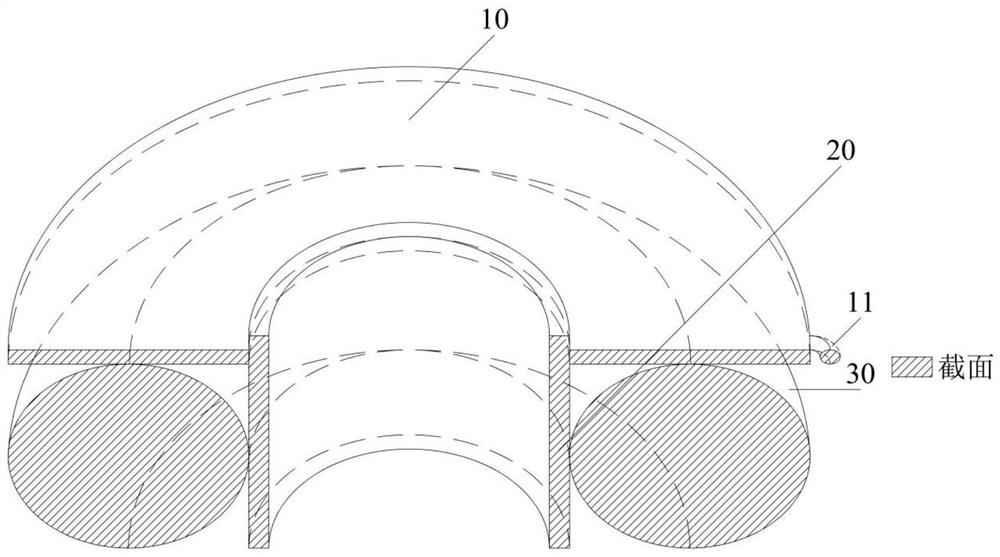

[0042] Embodiment 1 provides a kind of elastic ring electrode, such as Figure 1-5 shown, including: metal bracket and elastic ring conductor;

[0043] The metal bracket is composed of an upper annular part 10 and a lower hollow cylindrical part 20, and the upper part of the lower hollow cylindrical body 20 is connected to the inner ring of the upper annular part 10;

[0044] The elastic ring conductor includes an elastic liner 30 and a metal mesh conductor 40 coated on the surface of the elastic liner;

[0045] The elastic liner 30 is in the shape of a torus and is composed of an outer skin and fillers. In order to facilitate shaping and increase the contact area between the electrode mesh conductor and the ground surface, the outer skin is made of latex or rubber-like elastic material, and the filling The material is oily soil (plasticine), preferably, the making material of the liner is synthetic rubber.

[0046] The diameter and inner diameter of the elastic liner 30 aft...

Embodiment 2

[0069] Embodiment 2 provides a method for manufacturing the elastic ring electrode of Embodiment 1, comprising:

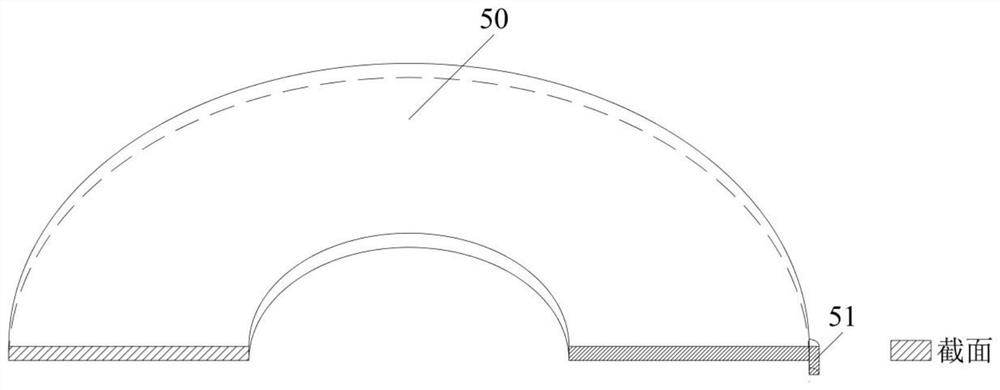

[0070] Step S1, using a lathe to process a 5mm thick copper plate into a first ring plate and a second ring plate, the first ring plate is used as the upper ring portion 10, and the second ring plate is used as the counterweight plate 50 ;

[0071] Step S2, using a lathe to process a 5mm thick copper plate into a hollow cylinder 20 as the lower hollow cylinder part;

[0072] Step S3, welding the inner wall of the upper annular part 10 to a designated position below the top of the outer wall of the lower hollow cylindrical part 20; the designated position is 5 mm to 10 mm from the top of the lower hollow cylindrical part 20.

[0073] Step S4, using about 210000mm 3 The oily soil is made into an oily soil cylinder with a diameter of 60mm and a length of 450mm. Cut the rubber film into a rectangle of 400mm*900mm, and then cover it outside the oily soil cylinder to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com