High-permeability emulsified asphalt permeable oil as well as preparation method and application thereof

A technology of emulsified asphalt and penetrating layer oil, which is applied to building components, building insulation materials, buildings, etc., to achieve the effects of prolonging the demulsification time, good film forming effect, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

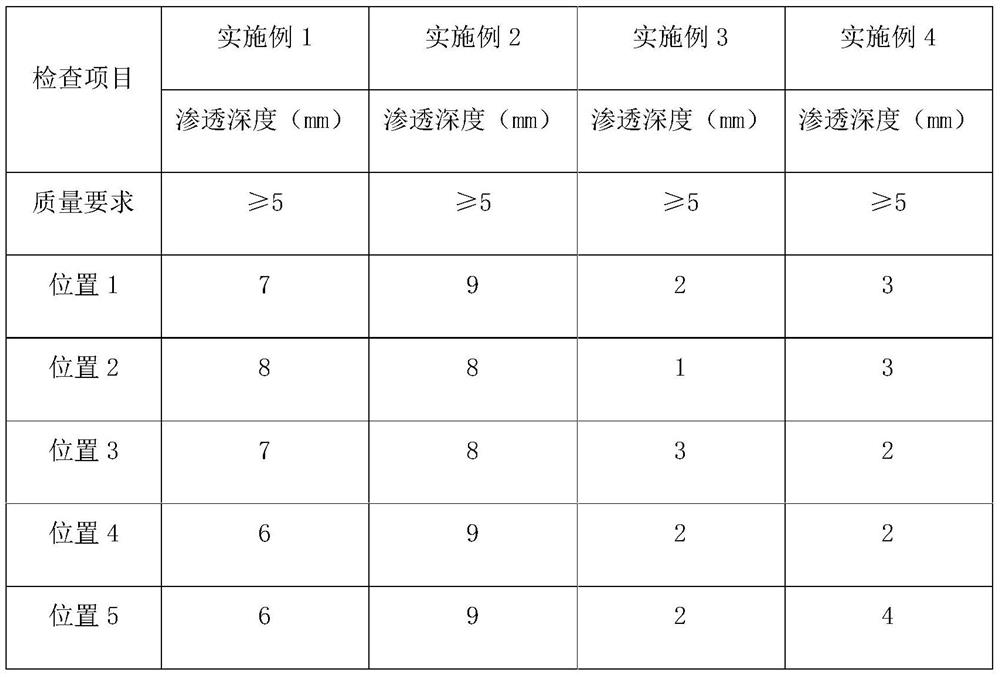

Examples

Embodiment 1

[0034] A high-permeability emulsified asphalt material, also known as high-permeability emulsified asphalt oil penetration, is made of the following raw materials in parts by weight: 45 parts of petroleum asphalt, 3 parts of emulsifier, 40 parts of water, 7 parts of kerosene, 3 parts of furfural oil, and 2 parts of additives share. Among them, the emulsifier is MQK-1M emulsifier, and the additive is CaCl 2 .

[0035] Its preparation method is as follows:

[0036] Step 1: Prepare various raw materials according to the above-mentioned high-permeability emulsified asphalt material ratio;

[0037]Step 2: Add the emulsifier to water at about 60°C, adjust the pH value to 3.0 with a pH regulator (35% HCl solution), and add additives to further dissolve the emulsifier. After fully dissolving, stir evenly, and then use hydrochloric acid again adjusting the pH value of the mixed liquid to 3.0 to prepare the mixture;

[0038] Step 3: After heating and melting 45 parts by weight of as...

Embodiment 2

[0045] A high-permeability emulsified asphalt material is composed of petroleum asphalt, emulsifier, water, permeable composite light components and additive raw materials. The percentage by weight of each raw material is: 42 parts of petroleum pitch, 2 parts of emulsifier, 40 parts of water, 10 parts of kerosene, 5 parts of furfural oil, and 1 part of additive. Among them, the emulsifier is MQK-1M emulsifier, and the additive is CaCl 2 .

[0046] The specific implementation process is basically the same as in Example 1, the difference is that in step 3, 42 parts by weight of asphalt is heated and melted to 140 ° C, mixed with 15 parts by weight of permeable composite light components; in step 4, it is 43 parts of aqueous solution and 57 parts by weight Part of the molten mixture was added to a colloid mill shearing machine for grinding for 3 minutes; the construction spraying temperature in step 6 was 90°C.

Embodiment 3

[0048] A high-permeability emulsified asphalt material is composed of petroleum asphalt, emulsifier, water, kerosene and additive raw materials. The percentage by weight of each raw material is: 40 parts of petroleum pitch, 1.8 parts of emulsifier, 47.9 parts of water, 10 parts of kerosene, and 0.3 part of additive. Among them, the emulsifier is a quaternary ammonium emulsifier, and the additive is CaCl 2 .

[0049] The specific implementation process is basically the same as that of Example 1, except that: in step 3, 40 parts by weight of asphalt is heated and melted to 140°C, and mixed with 10 parts by weight of permeable composite light components; in step 6, the construction spraying temperature is 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com