Fixed bed coal gasification furnace, fixed bed coal gasification and coal gasification hydrogen production system and process method

A coal gasification, fixed bed technology, applied in the petroleum industry, manufacturing combustible gas, energy input, etc., to achieve the effect of expanding scale and production capacity, improving energy efficiency and thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

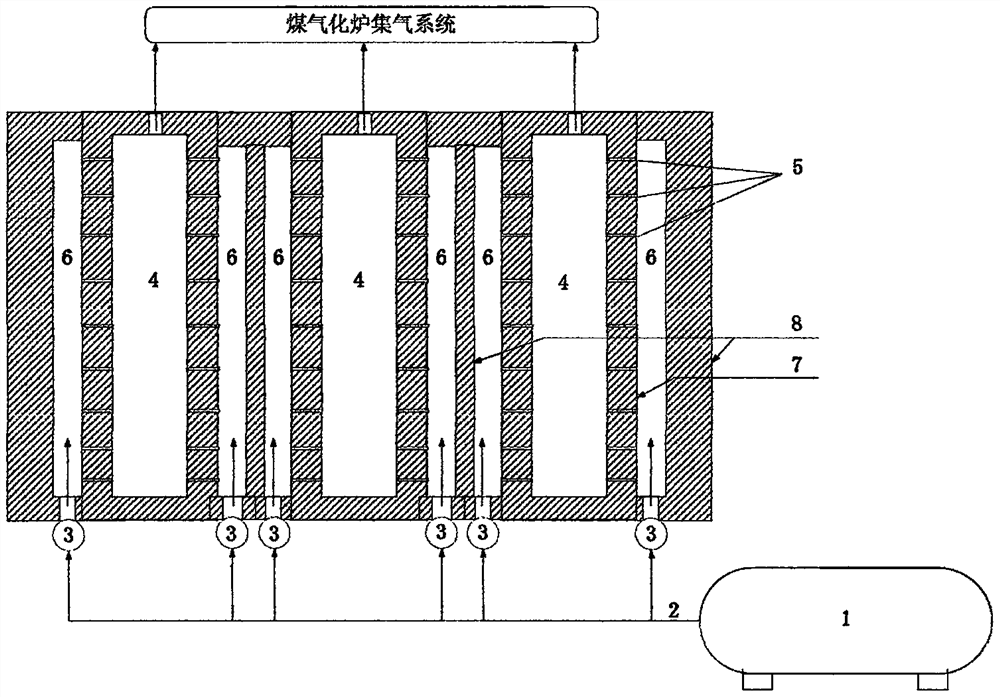

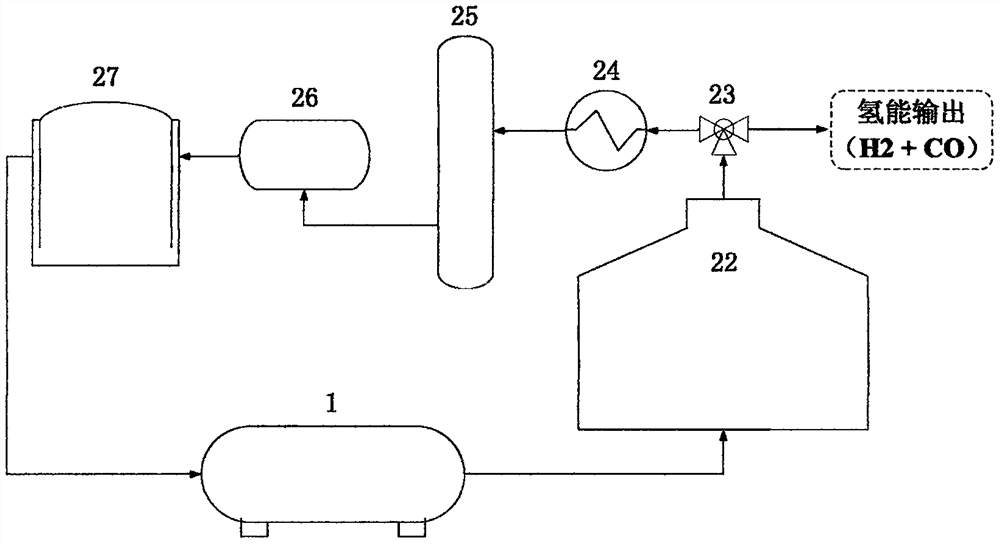

[0045] Implementation mode 1: new fixed bed coal gasification furnace, fixed bed coal gasification and coal gasification hydrogen production system

[0046] Fixed-bed coal gasifier of the present invention, its structure is as follows figure 1 as shown ( figure 1 The other units, structures, equipment, technology and processes of the coal gasifier not shown in the above can be the same as the new internal heating coal coking furnace or the modern traditional coal coking furnace, and are implemented by using the existing technology and will not be described in detail. ),include:

[0047] The furnace body is provided with several side-by-side coal gasification chambers (4), the coal gasification chambers (4) are used to fill the coal materials to be gasified, the coal gasification chambers (4) and the new internal heating coal coking Or the function and basic structure of the carbonization chamber of the modern coal coking furnace are the same, and are used for coal gasificati...

Embodiment approach 2

[0068] Implementation mode 2: Upgrading of the existing new internal heating coal coking furnace technology

[0069] For the new internal heating coal coking furnace system invented by patents [1] and [2], its implementation is mainly completed by adding mixed gas collection pipes and technical upgrading of the gas collection pipe network.

Embodiment approach 3

[0070] Implementation Mode 3: Upgrading of existing traditional coal coking furnace technology

[0071] For the existing traditional coal coking furnace, its implementation method includes referring to Embodiment 1, carrying out technical transformation on the existing coke oven body and carbonization chamber, and completing it by adding mixed gas collection pipes and technical upgrading and transformation of the gas collection pipe network .

[0072] The present invention has the following advantages: fixed bed coal gasifier and coal gasification and coal gasification hydrogen production equipment system

[0073] 1) Since the present invention adopts a fixed-bed coal gasifier with a similar structure and the same specifications as the existing traditional coal coke oven and its carbonization chamber, and uses high-temperature oxygen-deficient gas as the gasification agent, it realizes a clean, high-efficiency and low-cost large-scale coal gasifier. Large-scale to ultra-large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com