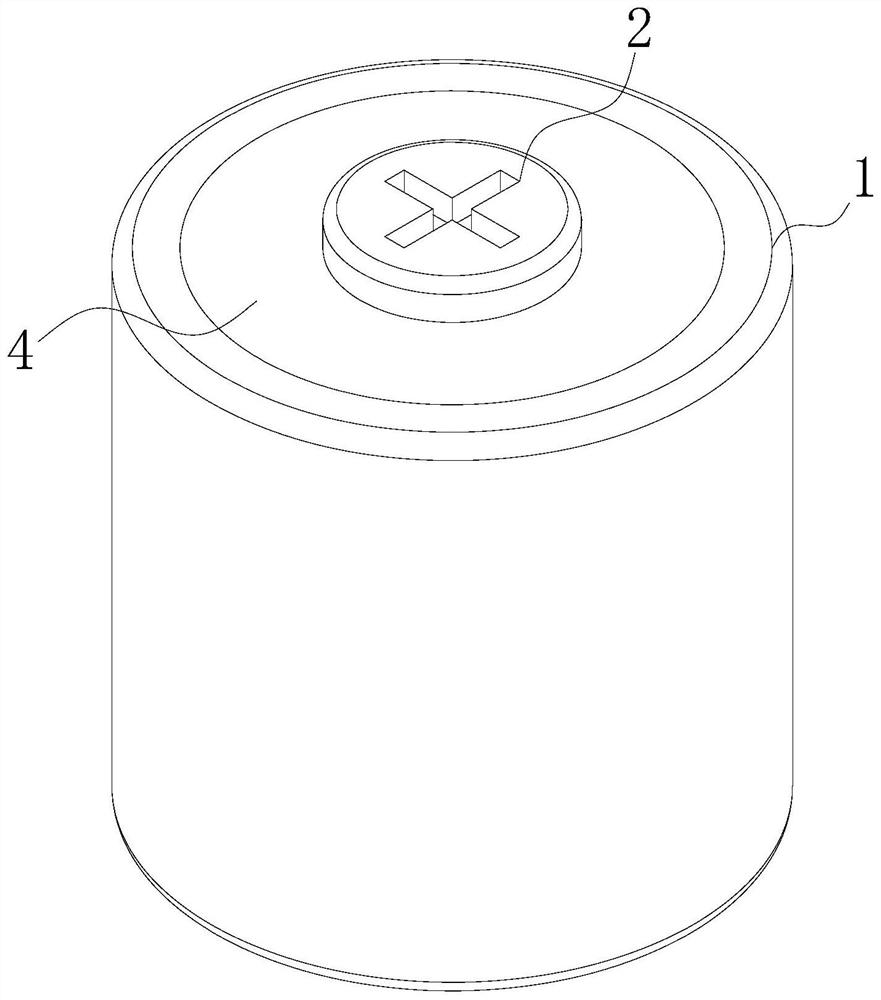

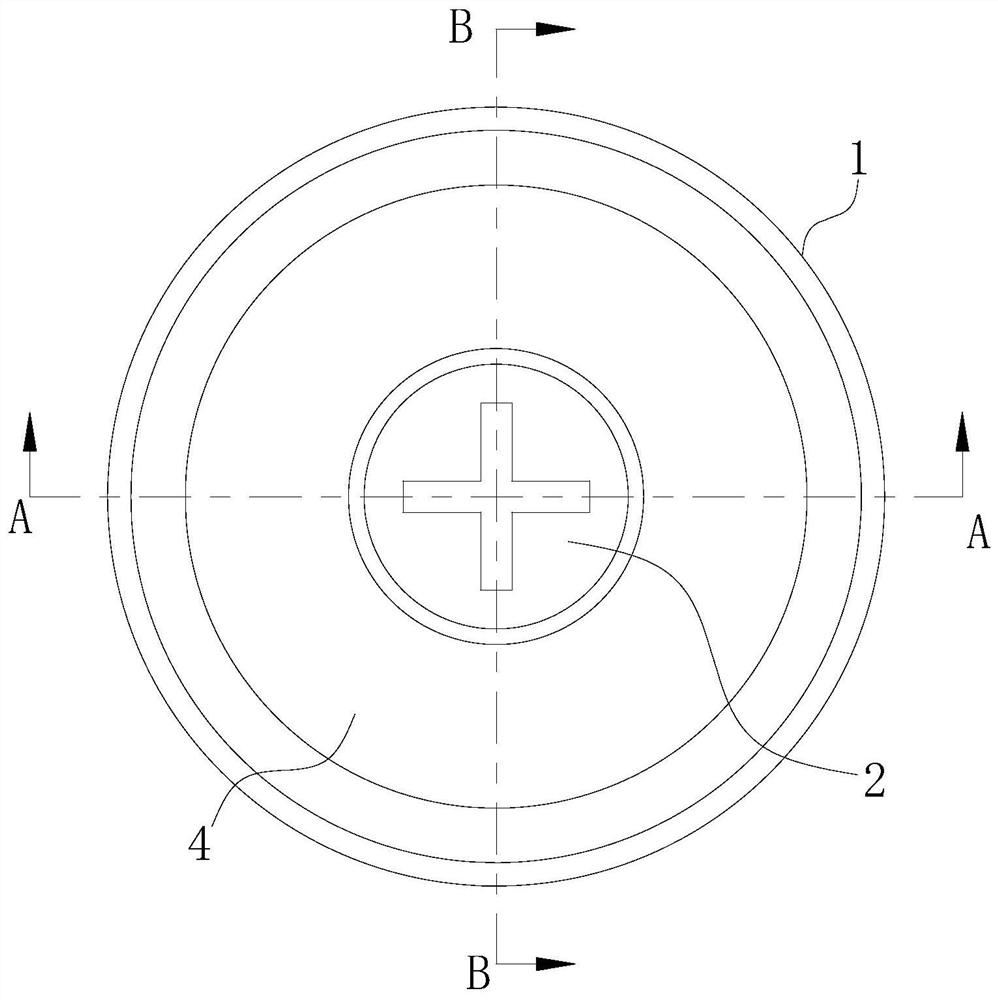

Magnesium alloy screw for ankle joint lower tibiofibular joint injury

A magnesium alloy and ankle joint technology, applied in the application field of magnesium alloy screws, can solve the problems of autologous bone absorption, mechanical defects, stress shielding, etc., and achieve the effects of avoiding shaking problems, improving fixation effect, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] As an embodiment of the present invention, the lower surface of the adjustment plate 7 is fixedly connected with a circle of uniformly arranged fixing columns 15, by opening corresponding fixing grooves near the bone injury site, and inserting the fixing columns 15 into the corresponding fixed The inside of the groove makes the universal screwer firmly fixed, and the fixed trauma surface of the bone is less;

[0038] When working, when the screwing column 2 is rotated, it can not only prevent the screwing column 2 from directly driving the rotation of the entire universal screwer, which will affect the normal screw 11 driving into the bone, but also because the universal screwer itself is compared with the screw 11 has a large volume, and when the universal screwer is fixed, the trauma to the bone is relatively large. By setting the fixed column 15, by fixing the fixed column 15 evenly arranged on the lower surface of the adjustment plate 7, and passing the fixed column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com