Equipment for preparing dry ice by utilizing cement kiln flue gas

A cement kiln and flue gas technology, applied in the cement field, can solve the problems of high transportation cost, high dry ice cost, small transportation radius, etc., and achieve the effects of improving economic benefits, high product value, and increasing processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

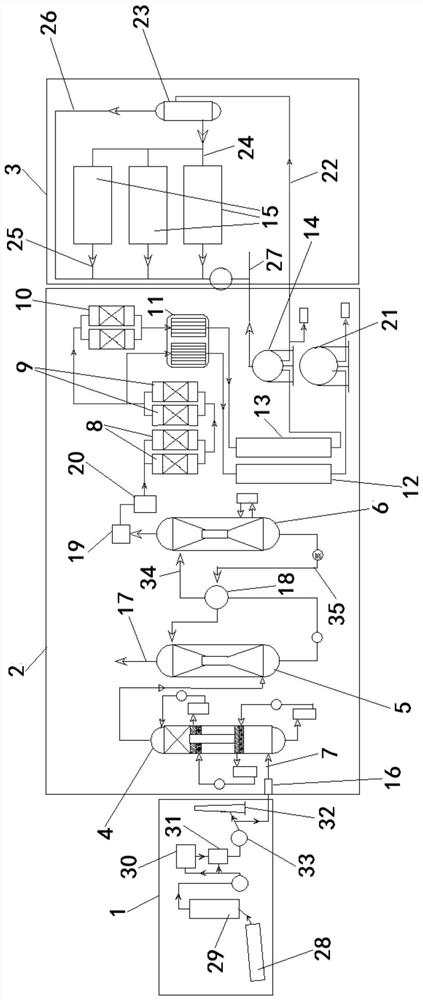

[0020] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

[0021] as attached figure 1 As shown, the present invention is a device for preparing dry ice from cement kiln flue gas, including a cement kiln system 1, a cement kiln flue gas carbon dioxide capture system 2, and a dry ice preparation system 3. The cement kiln flue gas carbon dioxide capture system 2 is A decarbonization water washing tower 4, an absorption tower 5, and an analysis tower 6 are set, the decarbonization water washing tower 4 is connected with the flue gas supply pipeline 7 of the cement kiln system 1, the decarbonization water washing tower 4 is connected with the absorption tower 5 at the same time, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap