Hard alloy material producing and machining system

A cemented carbide and processing system technology, applied in solid separation, sieve, grid, etc., can solve the problem of untimely synchronous picking operation of large-volume alloy particles, influence of alloy particle forming quality and forming speed, and inconvenience for regular work structure. Cleaning and other problems to avoid function reduction, dismantling, cleaning and maintenance, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

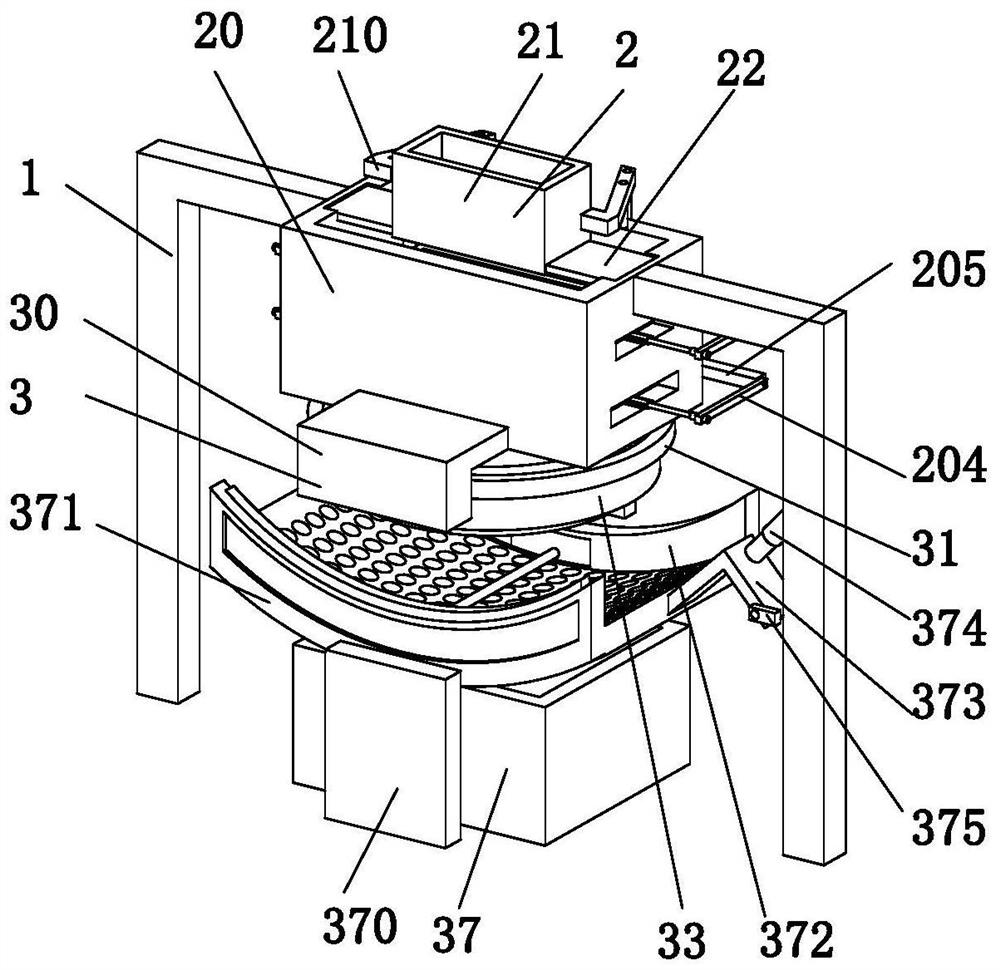

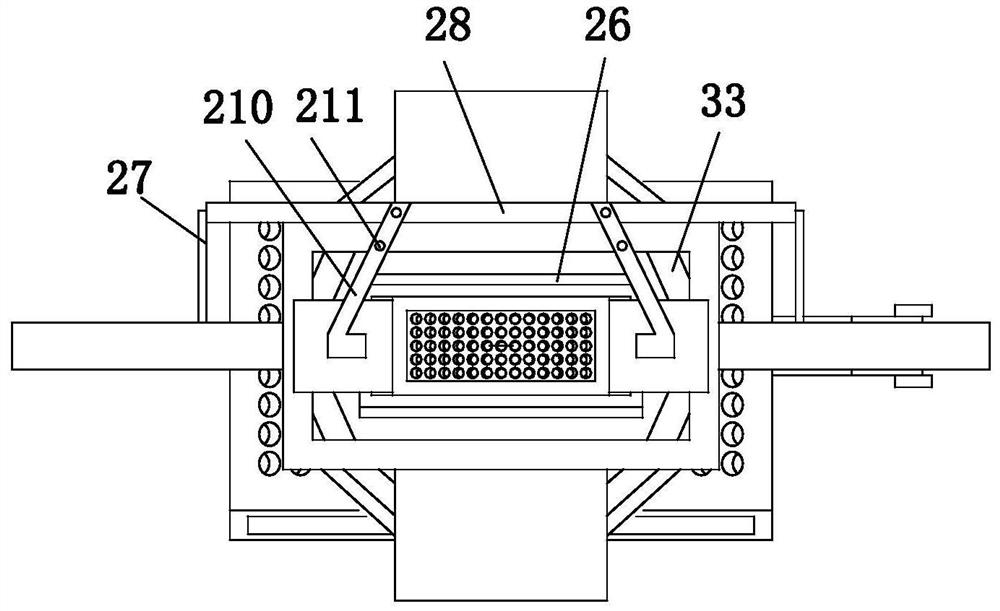

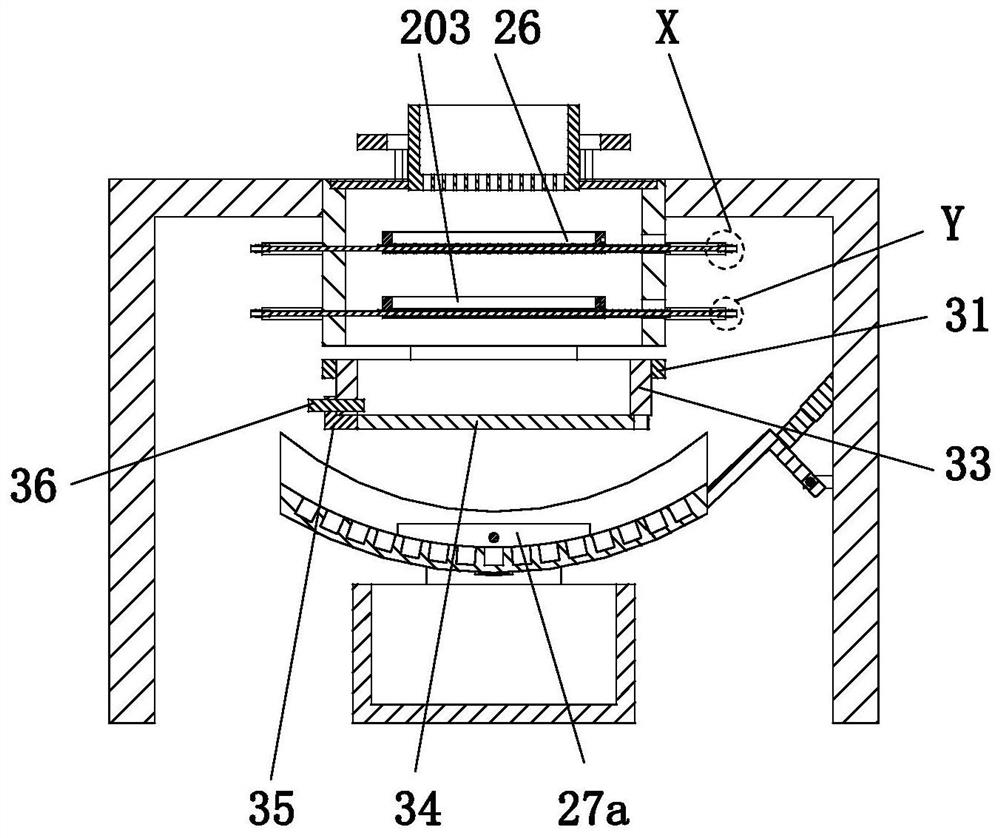

[0031] Such as Figure 1 to Figure 8 As shown, a cemented carbide material production and processing system includes a support 1, a mixing mechanism 2 and a granulation mechanism 3. The lower end of the support 1 is installed on the existing working ground, and the support 1 is arranged in a left-right symmetrical structure. A mixing mechanism 2 is installed between the upper ends of the brackets 1, and a granulation mechanism 3 is arranged at the lower end of the mixing mechanism 2.

[0032] The mixing mechanism 2 includes a return basket 20, a material storage box 21, a connecting plate 22, a connecting rod 23, a sleeve rod 24, a No. 1 electric slider 25, a forming plate 26, a connecting rod 27, a straight plate 28 and a No. 2 electric motor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com