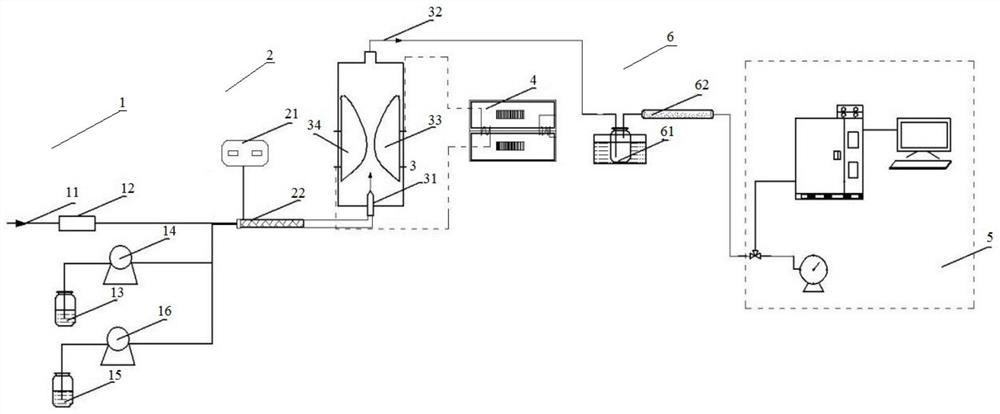

Hydrogen production device and hydrogen production method for reforming organic compounds through low-temperature plasmas

A technology of organic compounds, low temperature plasma, used in chemical instruments and methods, inorganic chemistry, hydrogen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

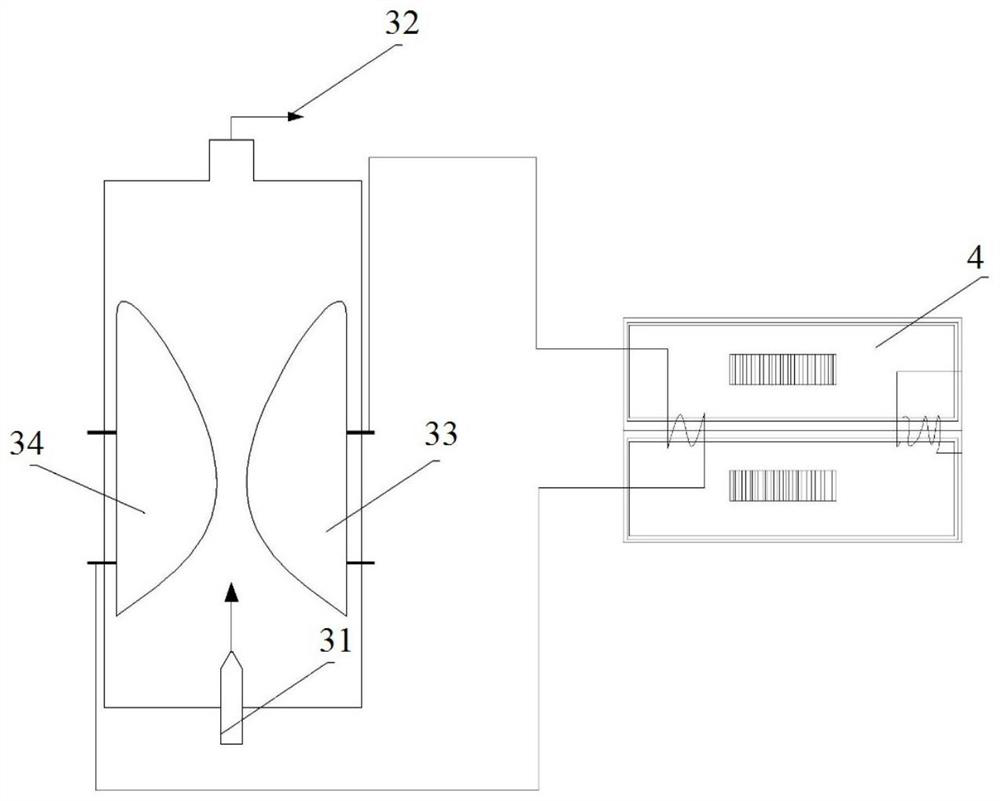

Method used

Image

Examples

Embodiment 1

[0074] Adopt the hydrogen production device of the low-temperature plasma reforming organic compound provided by the invention, the organic compound selects n-heptane (C 7 h 16 ). The main reaction formula of plasma reforming n-heptane to produce hydrogen can be described by formulas (1)-(4):

[0075] C 7 h 16 →CH 4 +2C 2 h 2 +C 2 h 4 +2H 2 (1)

[0076] o 2 +2CH 4 →2CO+4H 2 (2)

[0077] h 2 O+CH 4 →CO+3H 2 (3)

[0078] h 2 O+CO→CO 2 +H 2 (4)

[0079] In the above hydrogen production process, the carrier gas is air, and the flow rates of carrier gas, water and n-heptane are 15L / min, 18g / min, and 53g / min respectively; the output voltage of the high-voltage power supply is 800V, the output current is 0.5A, and the electrode distance is 6.5mm. The product mainly contains H 2 and CO 2 , hydrogen yield 98.9%.

Embodiment 2

[0081] The organic compound is n-octane (C 8 h 18 ), the main reaction formula of plasma reforming n-octane hydrogen production can be described by formula (5)-(7):

[0082] C 8 h 18 →2CH 4 +2C 2 h 2 +C 2 h 4 +H 2(5)

[0083] o 2 +CH 4 →CO 2 +2H 2 (6)

[0084] 2H 2 O+CH 4 →CO 2 +4H 2 (7)

[0085] In the above-mentioned hydrogen production process, the carrier gas is selected to contain 50 volume % O 2 Oxygen-enriched air is used as the carrier gas, and the flow rates of carrier gas, water and n-octane are 10L / min, 14g / min, and 58g / min respectively; the output voltage of the high-voltage power supply is 680V, the output current is 0.4A, and the electrode distance is 6mm. The product mainly contains H 2 and CO 2 , hydrogen yield 96.8%.

Embodiment 3

[0087] Organic compound selects toluene (C 7 h 8 ), the main reaction formula of plasma reforming toluene hydrogen production can be described by formula (8)-(11):

[0088] C 7 h 8 →CH 4 +iso-C 4 h 10 +H 2 +C (8)

[0089] o 2 +2C→2CO (9)

[0090] h 2 O+CH 4 →CO 2 +H 2 (10)

[0091] iso-C 4 h 10 +O 2 →CO 2 +H 2 (11)

[0092] In the above hydrogen production process, the carrier gas is air, and the flow rates of carrier gas, water and toluene are 18L / min, 27g / min, and 30g / min respectively; the output voltage of the high-voltage power supply is 710V, the output current is 0.42A, and the electrode distance is 6.5mm. The product mainly contains H 2 and CO 2 , 93.9% hydrogen yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com