Method and device for separating C9 aromatic hydrocarbon mixture

A technology of carbon-nine aromatics and mixtures, which is applied in the field of separation of polymethyl aromatics, can solve problems such as waste of resources, achieve comprehensive utilization, wide product application range, and increase added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

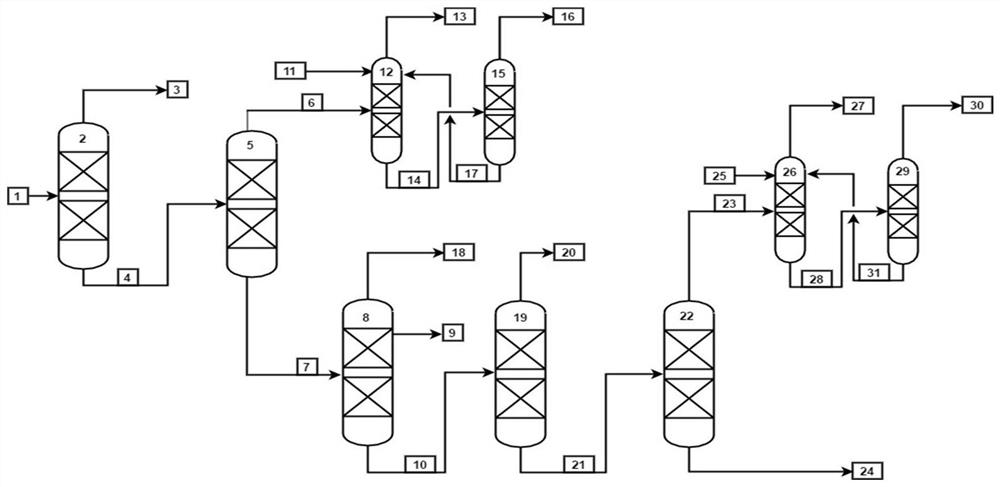

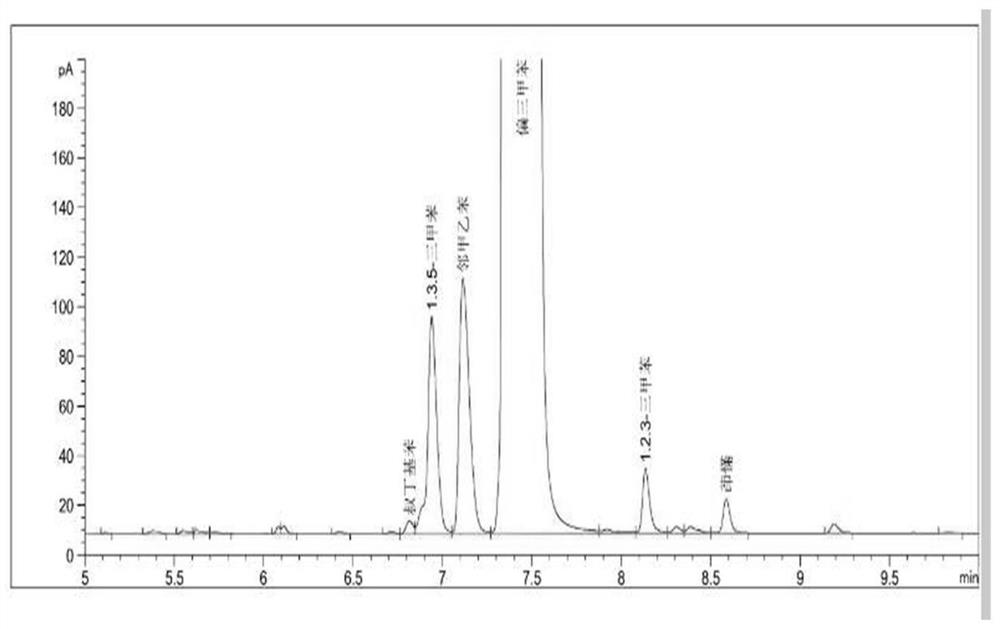

[0100] According to the following steps, in the refinery reforming carbon nine-heavy aromatics raw materials, we can separate unsytrimethylbenzene, mesitylene, trimethylbenzene and by-product o-methylethylbenzene:

[0101] (1) Send the reformed carbon nine-heavy aromatics raw material from the refinery into the first light removal tower 2 at a feed rate of 10t / h. The operating conditions of the first light removal tower 2 are kettle temperature 133°C, top temperature 100 ℃; top pressure 15KPa.A; reflux ratio 3.5; the amount of light components output by the light component transfer pump 3 is 1.65t / h, the amount sent by the first light removal tower kettle transfer pump 4 to the removal of mesitylene tower 5 is 8.35t / h;

[0102] (2) The operating conditions of the mesitylene removal tower 5 are: kettle temperature 138°C, top temperature 111°C; top pressure 7KPa.A; reflux ratio 4.5; enriched mesitylene component that is exported by the mesitylene delivery pump 6 The amount sent...

Embodiment 2

[0130] Compared with Example 1, the difference is that the mol ratio of trimethyl trimesate and n-octanol in the extraction solvent of step (4) is 3:1.

[0131] Three kinds of final products and one kind of by-product are detected to gained, and the result is:

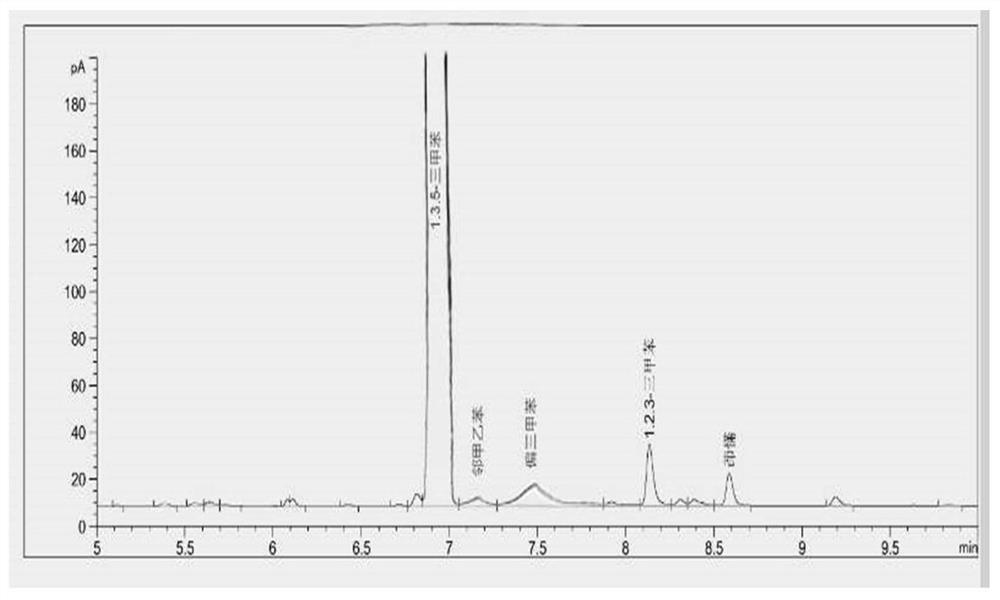

[0132] The purity of trimethylbenzene in the final product is 99.29% (wt);

[0133] The purity of mesitylene in the final product is 98.63% (wt);

[0134] The purity of trimethylbenzene in the final product is 99.10% (wt);

[0135] The purity of the by-product o-methylethylbenzene is 93.28% (wt).

[0136] Compared with Example 1, the mesitylene yield drops (relative to the content in the raw material) to 80.29%, a decline of 6.42%; the o-methylethylbenzene yield drops (relative to the content in the raw material) about 10%.

Embodiment 3

[0138] Compared with Example 1, the difference is that the mol ratio of trimethyl trimesate and n-octanol in the extraction solvent of step (4) is 5:1.

[0139] Three kinds of final products and one kind of by-product are detected to gained, and the result is:

[0140] The purity of trimethylbenzene in the final product is 99.25% (wt);

[0141] The purity of mesitylene in the final product is 98.68% (wt);

[0142] The purity of trimethylbenzene in the final product is 99.20% (wt);

[0143] The purity of the by-product o-methylethylbenzene is 95.61% (wt).

[0144] Compared with Example 1, the mesitylene yield rises (relative to the content in the raw material) to 86.92%, an increase of 0.21%; the o-methylethylbenzene yield rises (relative to the content in the raw material) by about 1%; but the energy of the whole device Consumption increased by about 6.5%, showing a relatively large negative correlation in the economy. And the purity of the mesitylene product drops below 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com