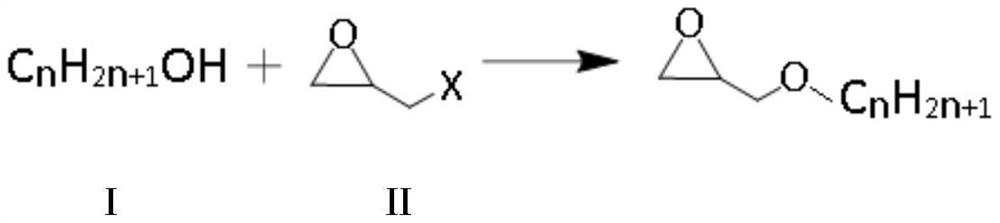

Preparation method of alkyl glycidyl ether

A technology of glycidyl ether and alkyl, which is applied in the field of preparation of alkyl glycidyl ether, can solve the problems of low yield and low purity, and achieve the effects of high yield, high product purity and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In order to make the continuous flow substitution reaction more efficient, in a preferred embodiment, the above-mentioned preparation method comprises the following steps: mixing the alkyl alcohol with the epihalohydrin to form the first raw material liquid; mixing the catalyst with the liquid caustic soda, forming a second raw material liquid; sending the first raw material liquid and the second raw material liquid into a microchannel reactor for continuous flow substitution reaction to obtain alkyl glycidyl ether. In this way, the reaction monomers are mixed in advance, the catalytic gas is mixed, and then passed into the microchannel reactor for reaction, which is conducive to the full contact of each reaction raw material, so as to minimize the reaction time and obtain higher yield.

[0036] In the actual operation process, the first raw material liquid and the second raw material liquid can be placed in two liquid storage units respectively, and then the two raw ma...

Embodiment 1

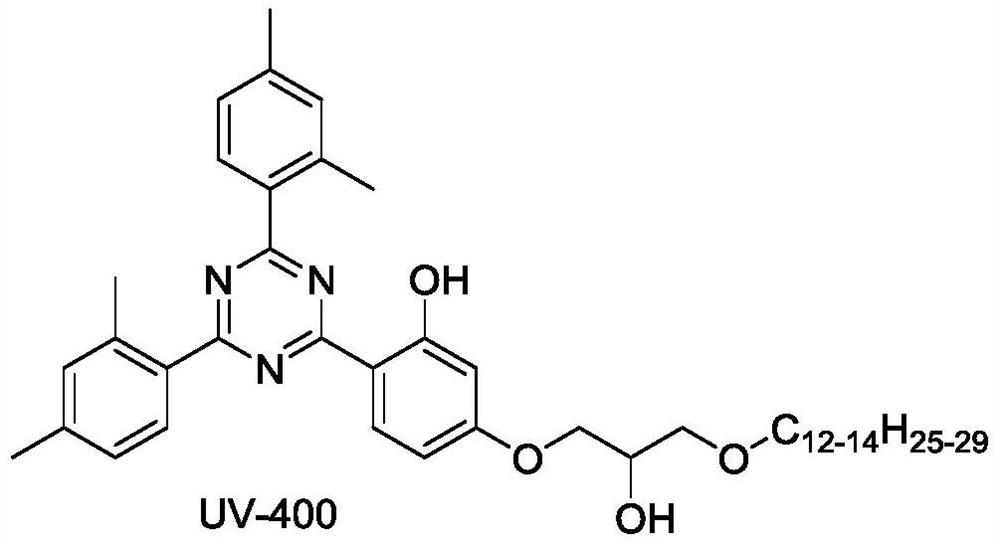

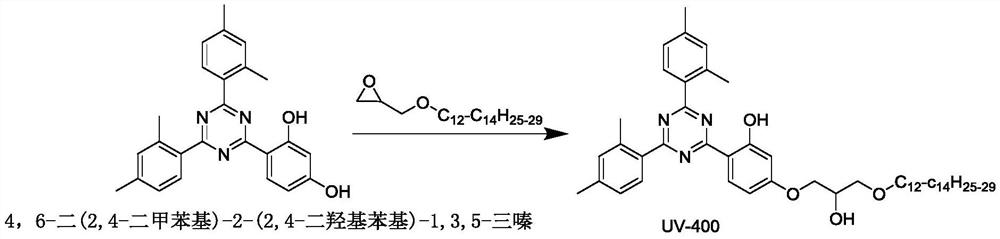

[0043] Prepared mixed long carbon chain alkyl glycidyl ether in this embodiment, concrete operation is as follows:

[0044] At room temperature (about 25°C), 196g (about 1.0mol) of C 12 -C 14 Add long-chain mixed alkyl alcohol (commercially available), 111g (1.2mol) epichlorohydrin into a single-necked flask, and magnetically stir until the materials are completely mixed to form the first raw material solution; 48g (1.2mol) NaOH, 300ml water and 11g (0.03mol) of ethyltriphenylphosphine bromide were added to a single-necked round-bottomed flask, stirred electromagnetically, until completely mixed to form a second raw material solution;

[0045] Turn on the heat exchange system of the microchannel reactor, set the temperature of the hot oil to 50°C, and start the two feeding pumps A and B after the outlet temperature of the hot oil in the microchannel reactor is 50±0.5°C, and the feeding pump A delivers the first Raw material liquid, feeding pump B transports the second raw ma...

Embodiment 2

[0049] The difference from Example 1 is:

[0050] Turn on the heat exchange system of the microchannel reactor, set the temperature of the hot oil at 60°C to the outlet temperature of the hot oil of the microchannel reactor at 60±0.5°C, and then start two feeding pumps A and B, and the feeding pump A delivers the first raw material Liquid, feeding pump B transports the second raw material liquid. Wherein, the feeding speed of the first raw material liquid and the second raw material liquid is both 20ml / min, the retention time of the material is 1.2min, continuous feeding and continuous discharging.

[0051] Use a 1000ml four-neck round bottom flask to receive the reaction solution, then let the reaction solution stand, separate the lower aqueous phase, add a small amount of water, wash once, carry out vacuum distillation on the organic phase, collect 180-190 ° C fractions (2-3mmHg), The product is a colorless, slightly viscous liquid with a yield of 83% and a gas chromatograp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com