Lithium carbonate terpolymer and preparation method thereof

A technology of lithium carbonate terpolymer and copolymer, applied in the field of lithium carbonate terpolymer and its preparation, lithium ion polymer and its preparation, can solve the problem of capacity deterioration, peeling of electrode adhesive layer, reduction of PVDF phase Capacitance and other problems to achieve the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] This embodiment provides a lithium carbonate terpolymer.

[0085] A kind of lithium carbonate terpolymer provided by the present embodiment is to comprise:

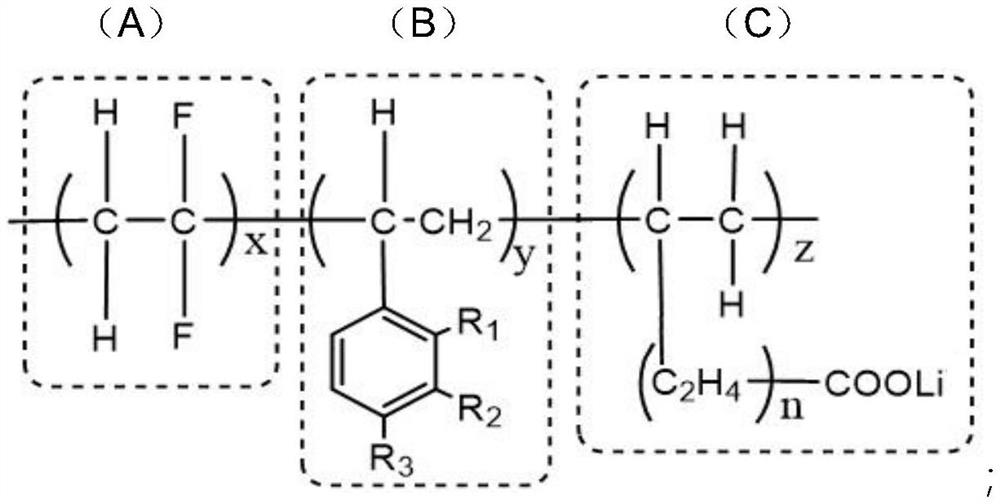

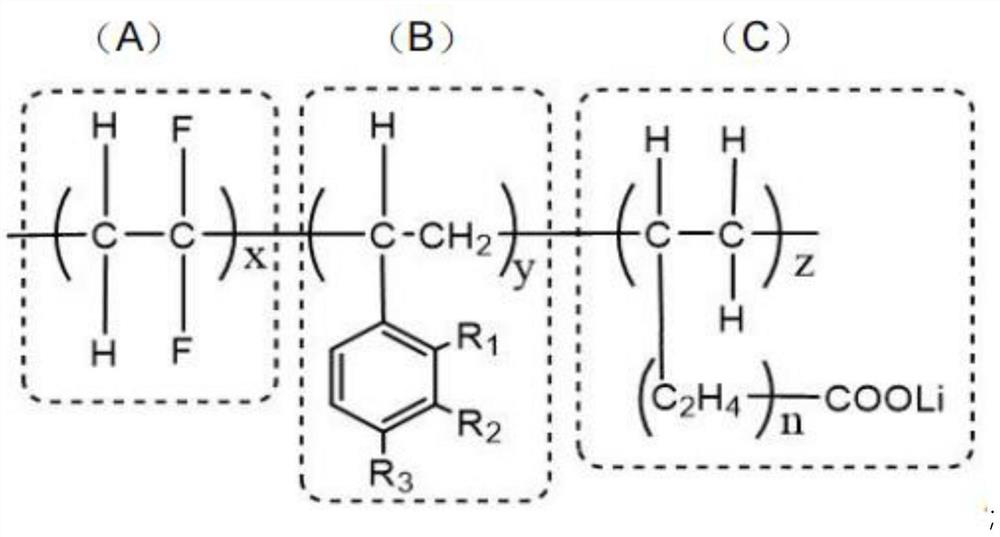

[0086] Polyvinylidene fluoride structural unit (A) composed of x mole parts of vinylidene fluoride monomer, vinylbenzyl structural unit (B) composed of y mole parts of vinylbenzyl monomer, and z mole parts of vinyl-alkyl carbonate A copolymer of vinyl-alkyl lithium carbonate structural units (C) composed of three compound structural units composed of lithium monomers; and

[0087] The copolymer has the following general structural formula:

[0088]

[0089] in:

[0090] In the vinylbenzyl monomer, it:

[0091] R 1 For -H, -Br, -Cl, -CF 3 , -CH 3 ;

[0092] R 2 For -H, -Br, -C=O, -CH 3 , -O-CH 3 ;

[0093] R 3 For -H, -Br, -CH 2 Br, -COOH, -Ph, -CH 3 , -O-CH 3 ;

[0094] In the vinyl-alkyl lithium carbonate monomer: n is an integer greater than or equal to 1; and

[0095] The respective molar fra...

Embodiment 2

[0112] This embodiment provides a preparation method of a lithium carbonate terpolymer.

[0113] A preparation method of a lithium carbonate terpolymer provided by the present embodiment comprises the following steps:

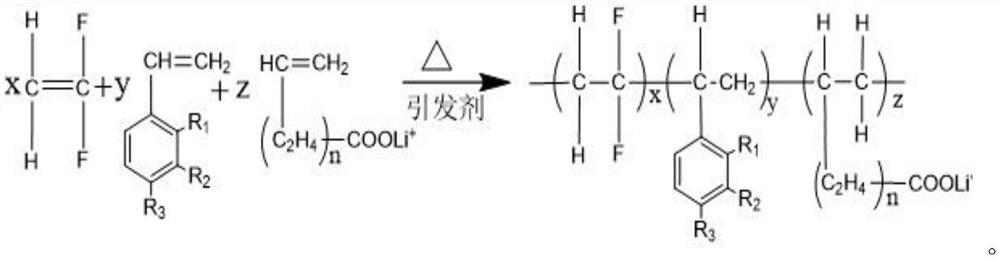

[0114] In the reaction device, vinylidene fluoride monomer, vinylbenzyl monomer and ethylene were added according to the respective mole fractions of polyvinylidene fluoride structural unit, vinylbenzyl structural unit and vinyl-alkyl lithium carbonate structural unit. The base-alkyl lithium carbonate monomer and the initiator are copolymerized by the polymerization reaction method to make the lithium carbonate terpolymer, and its reaction formula is:

[0115]

[0116] Further, in the above-mentioned preparation method:

[0117] The reaction device adopts a high pressure reactor;

[0118] In the step of adding vinylidene fluoride monomer, vinylbenzyl monomer, vinyl-alkyl lithium carbonate monomer and initiator respectively, it specifically includes:

[01...

example 1

[0147] In an autoclave with a tolerance of 10MPa, the structural formula of CH is added. 2 =CH-C 6 H 5 of vinylbenzyl monomers, and the structural formula CH 2 =CH-C 2 H 4 -COOLi + The vinyl-alkyl lithium carbonate monomer and benzoyl peroxide initiator are repeatedly evacuated to remove oxygen, and then, under a nitrogen atmosphere, the structural formula is CH 2 =CF 2 of vinylidene fluoride gas;

[0148] in:

[0149] by the structural formula CH 2 =CF 2 The polyvinylidene fluoride structural unit composed of the vinylidene fluoride gas, the structural formula is CH 2 =CH-C 6 H 5 The vinylbenzyl structural unit of the vinylbenzyl monomer, and the structural formula CH 2 =CH-C 2 H 4 -COOLi + The molar fraction ratio of the vinyl-alkyl lithium carbonate structural units constituted by the vinyl-alkyl lithium carbonate monomer is:

[0150] Vinylidene fluoride structural unit: vinylbenzyl structural unit: vinyl-alkyl lithium carbonate structural unit=0.55:0.30:0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com