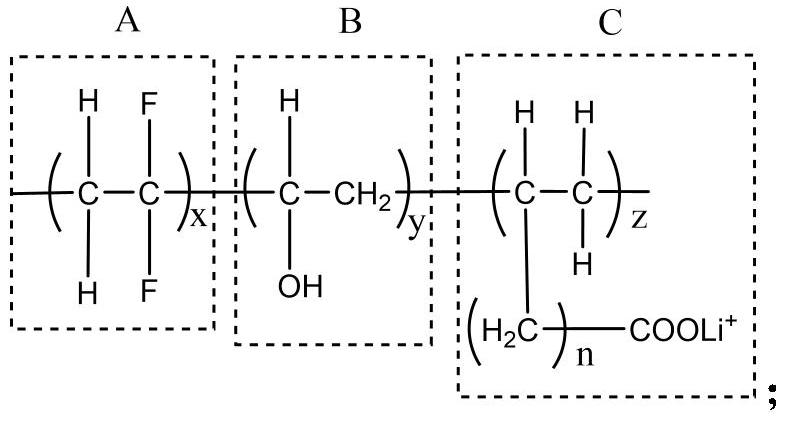

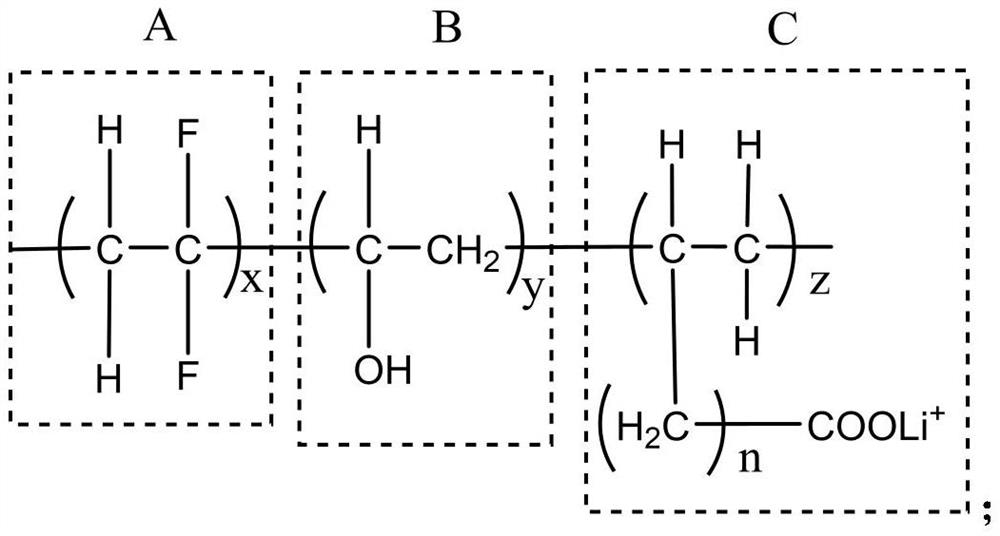

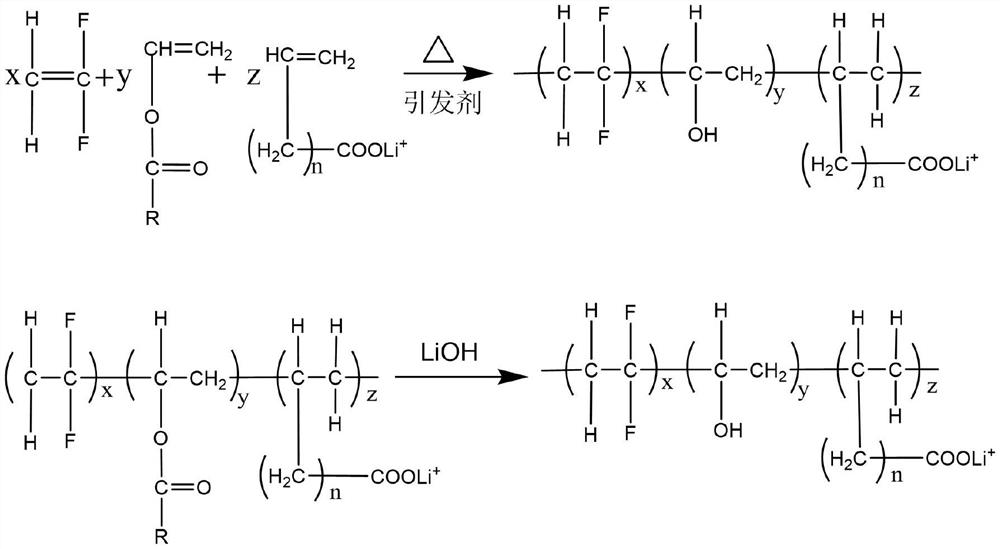

Vinylidene fluoride terpolymer and preparation method thereof

A vinylidene fluoride terpolymer, vinylidene fluoride technology, applied in electrical components, circuits, battery electrodes, etc., can solve the problems of low ion transmission efficiency, poor compatibility of blended PVDF, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of vinylidene fluoride terpolymer, the steps are as follows:

[0049] (1) Add vinyl acetate (vinyl ester monomer), vinyl lithium carbonate monomer CH 2 =CH-CH 2 -COOLi + and copolymerization initiator benzoyl peroxide and vacuumize and charge nitrogen;

[0050] (2) Under the protection of nitrogen, the vinylidene fluoride monomer CH 2 = CF 2 , keep the pressure at 1.5MPa, slowly raise the temperature to 100°C for 24 hours, and stir the reactants during the whole reaction process, wherein the molar ratio of vinyl lithium carbonate monomer, vinyl ester monomer and vinylidene fluoride monomer is 1:0.15 :0.20;

[0051] (3) be cooled to room temperature, open the high-pressure airtight reactor and emit unreacted gas to obtain the terpolymer emulsion;

[0052] (4) After the terpolymer emulsion is demulsified by the ethanol solution, it is washed several times to remove the emulsifier and unreacted monomers, dried and dissolved in the alcohol solutio...

Embodiment 2

[0054] A preparation method of vinylidene fluoride terpolymer, which is basically the same as Example 1, except that the vinyl ester monomer is vinyl benzoate, vinyl lithium carbonate monomer, vinyl ester monomer and vinylidene fluoride monomer The molar ratio of the body is 1:0.15:0.25.

Embodiment 3

[0056] A preparation method of vinylidene fluoride terpolymer, which is basically the same as Example 1, except that the molar ratio of vinyl lithium carbonate monomer, vinyl ester monomer and vinylidene fluoride monomer is 1:0.15:0.30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com