Low-cost long-service-life fast-built hard rock pipe gallery tunnel

A long-life, low-cost technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as high cost of excavation, cost of transporting construction waste to pollute the environment, ground uplift or subsidence, etc., to improve safety and reliability , reduce the risk of communication interference, the effect of less hard rock cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

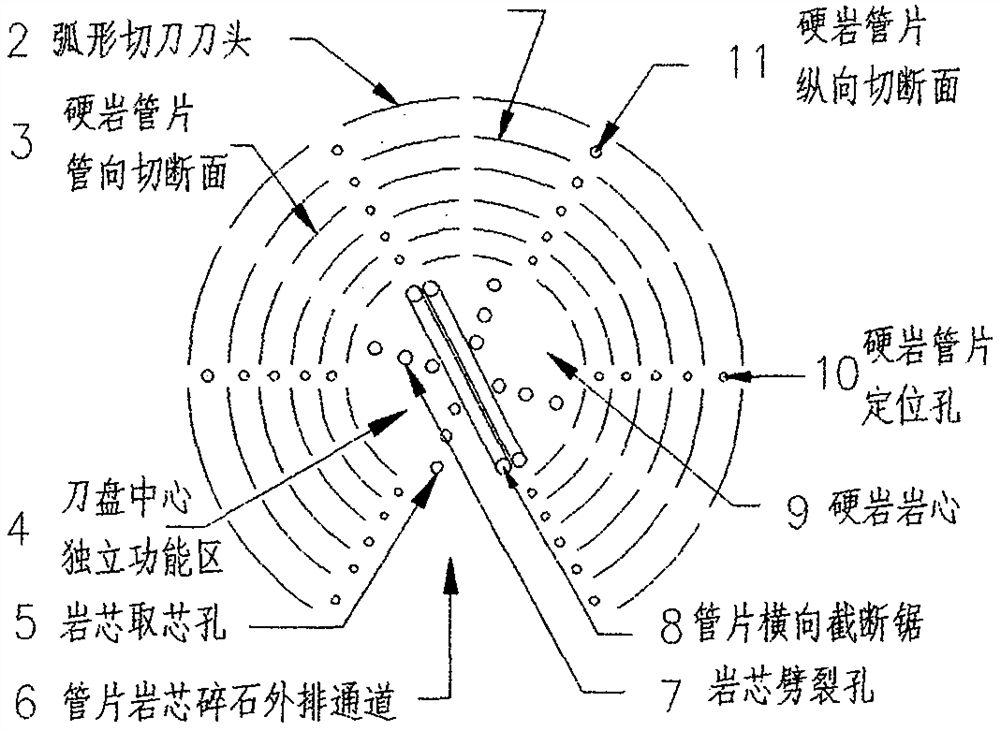

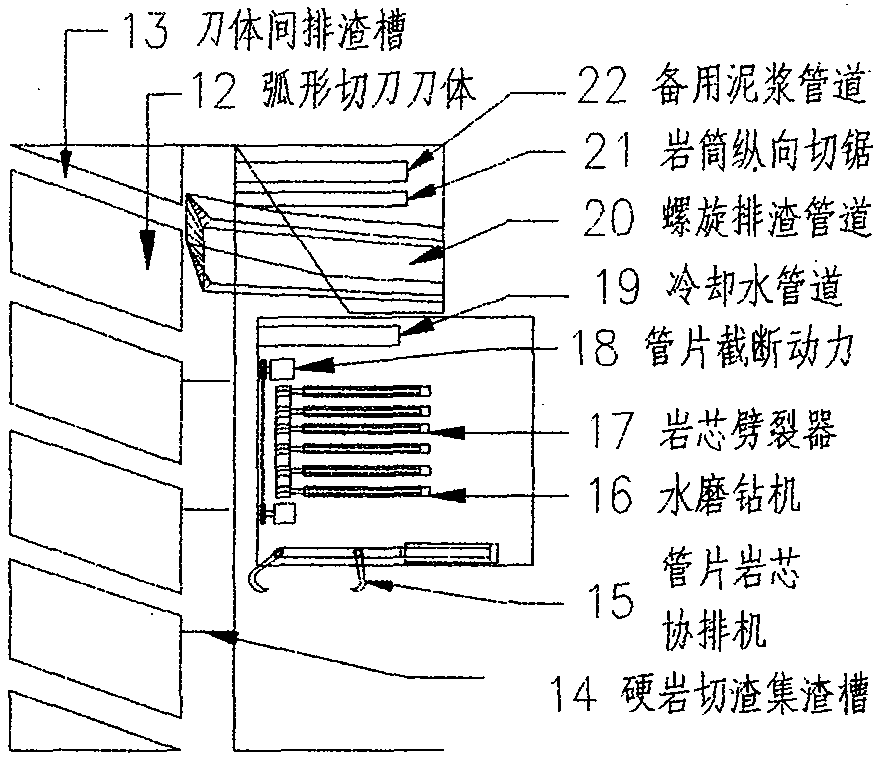

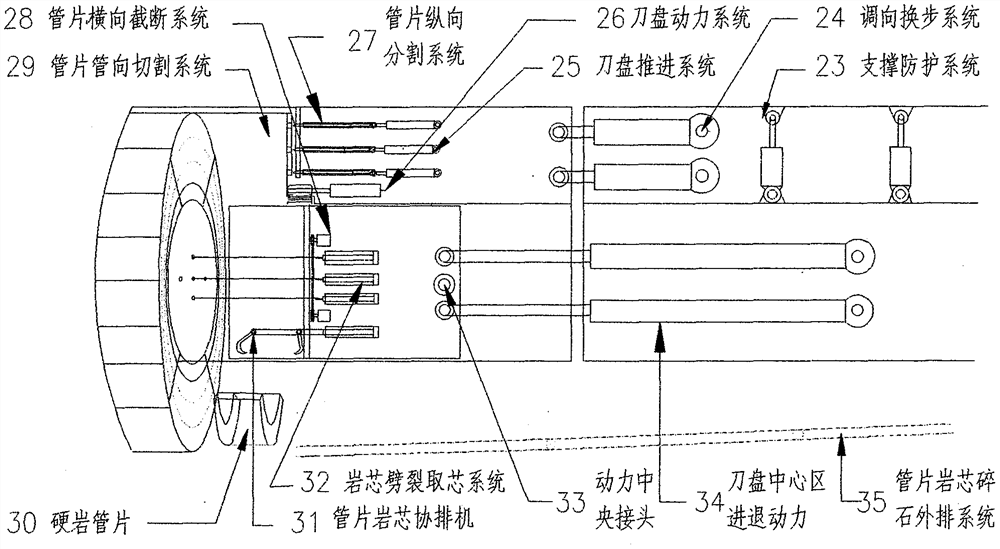

[0044] The specific embodiment is further described with reference to the accompanying drawings:

[0045] The invention provides a low-cost, long-life and rapid construction of a hard rock pipe gallery tunnel, which includes: 1 split hard rock excavation cutterhead, 2 arc cutters, 3 hard rock pipe-to-section sections, 4 cutterhead central functional areas, and 5 core rocks Coring hole, 6 tube piece rock core gravel channel, 7 core rock splitting hole, 8 tube piece transverse cutting saw, 9 hard rock core, 10 tube piece positioning hole, 11 hard rock longitudinal section, 12 arc cutter knife body, 13 slag discharge ditch between cutter bodies, 14 hard rock slag cutting and slag collection tank, 15 tube schist core discharge system, 16 water mill drilling rig, 17 core rock splitter, 18 segment cutting power, 19 cooling water pipeline, 20 rows Slag system, 21 longitudinal sawing of rock tube, 22 mud pipeline, 23 support and protection system, 24 direction adjustment and step chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com