Novel method for preparing chirped optical fiber bragg grating by means of uniform grating mask plate

A Bragg grating and chirped fiber technology, applied in cladding fibers, optical waveguide light guides, light guides, etc., can solve the problems of fiber life and performance effects, fiber bending process affecting chirped modulation accuracy, etc., to save production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: A new method for preparing chirped fiber Bragg gratings by means of a uniform grating mask

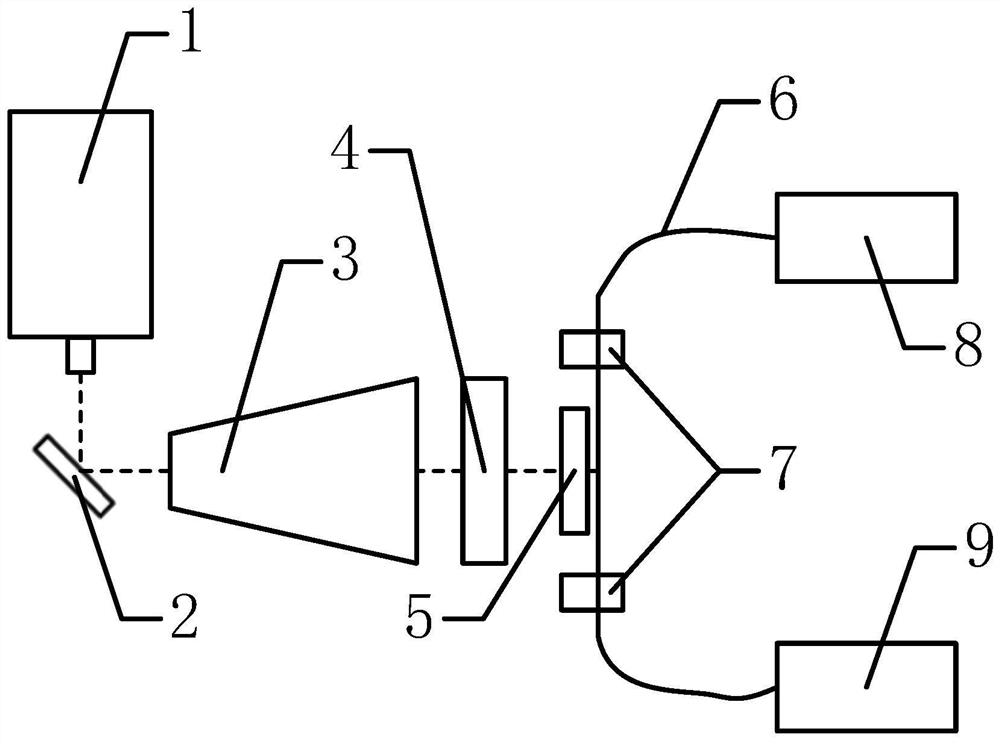

[0026] The CFBG writing system that the present invention uses is as figure 1 As shown, the preparation steps are as follows:

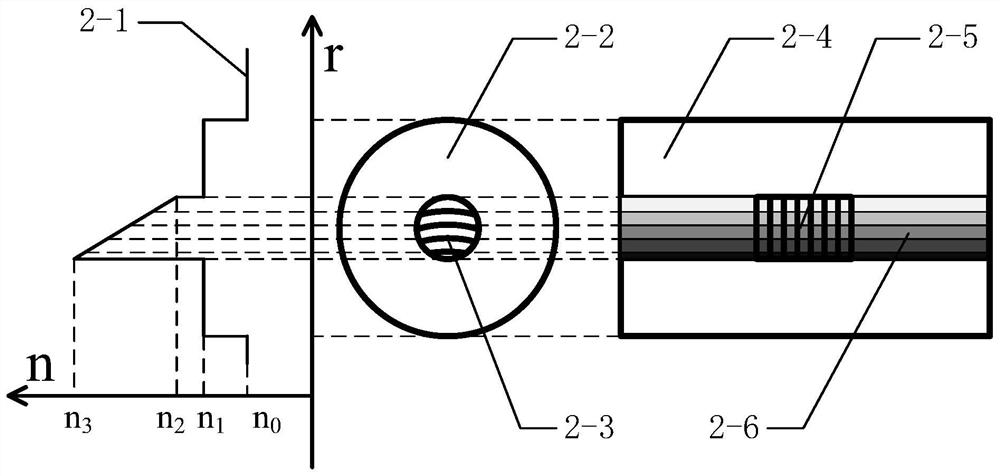

[0027] Step 1: Set the writing parameters of the excimer laser 1, and adjust the relative positions of the mirror part 2, the beam expander part 3 and the cylindrical lens part 4 in the writing system to collimate the ultraviolet laser beam so that it can be accurately focused on the surface to be written. The position of the core of the incoming optical fiber 6.

[0028] Step 2: According to design requirements, select a uniform grating mask with appropriate parameters, and place it on the mask holder to form the uniform grating mask part 5 .

[0029] Step 3: Take a single stress element optical fiber 6, peel off the coating layer from the section to be written into the CFBG, fix it on the optical fiber fixture after cleaning, the optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com