Heavy metal ion compound stabilizer and preparation method thereof

A technology for compounding stabilizers and heavy metal ions, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of not having broad-spectrum stabilizing effects of heavy metals, and achieves easy operation, simple preparation method, Environmental Risk Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation process of the adsorption leavening agent powder is as follows: sort the adsorption leavening agent to remove impurities, remove large particles with a diameter of more than 1cm, dry at 38-42°C with hot air until the moisture content is not greater than 10%, then break, pass 60-80 Mesh sieve to obtain adsorption leavening agent powder.

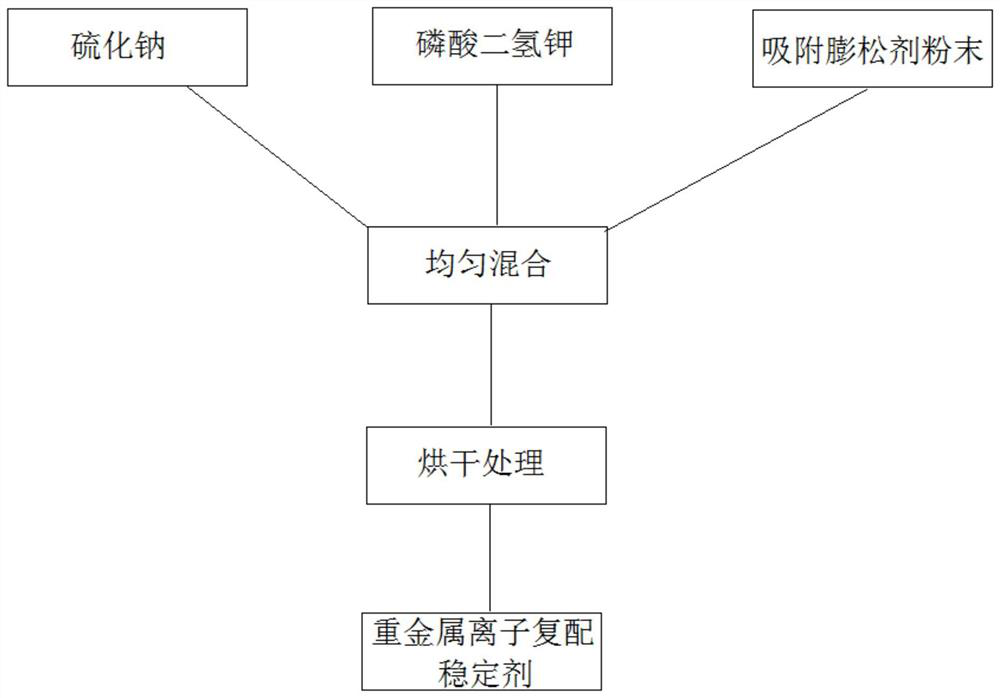

[0044] The specific preparation steps of a kind of heavy metal ion compound stabilizer of the present invention are as follows:

[0045] Step 1, take the amount of each component according to the proportion;

[0046] Step 2, sodium sulfide and potassium dihydrogen phosphate taken by weighing in step 1 are respectively configured into sodium sulfide saturated solution and potassium dihydrogen phosphate saturated solution;

[0047] Step 3, slowly mixing the saturated solution of sodium sulfide and the saturated solution of potassium dihydrogen phosphate under stirring conditions to obtain a mixed solution;

[0048] Step ...

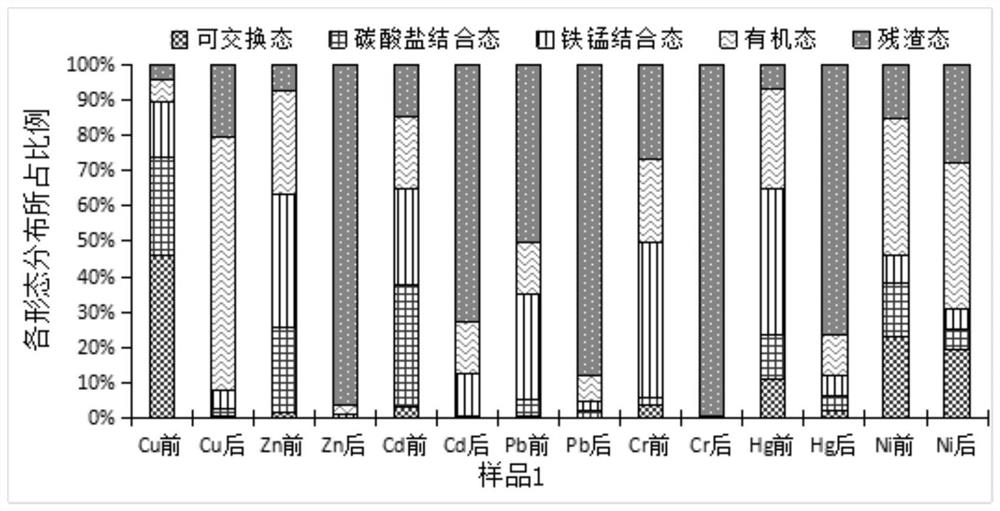

Embodiment 1

[0053] A heavy metal ion complex stabilizer is composed of the following components by mass percentage: 2.5% sodium sulfide, 1.0% potassium dihydrogen phosphate, 96.5% mushroom slag powder, and the sum of the above mass percentages is 100%.

[0054] Prepare above-mentioned heavy metal ion complex stabilizer, concrete preparation steps are as follows:

[0055] Step 1. Weigh 2.5% of sodium sulfide, 1.0% of potassium dihydrogen phosphate, and 96.5% of mushroom residue powder, and the sum of the above mass percentages is 100%.

[0056] Step 2, sodium sulfide and potassium dihydrogen phosphate taken by weighing in step 1 are respectively configured into sodium sulfide saturated solution and potassium dihydrogen phosphate saturated solution;

[0057] Step 3, slowly mixing the saturated solution of sodium sulfide and the saturated solution of potassium dihydrogen phosphate under stirring conditions to obtain a mixed solution;

[0058] Step 4. Slowly add the mixed solution to the mus...

Embodiment 2

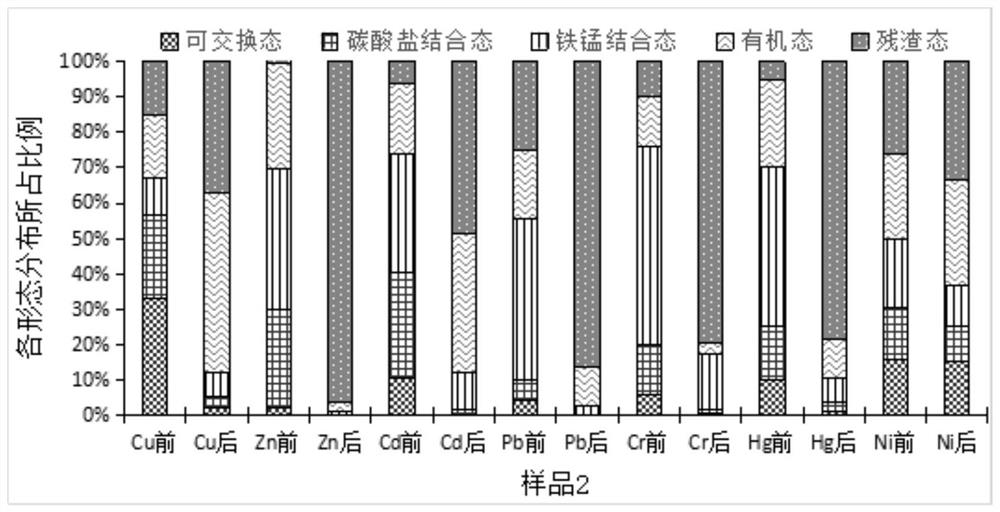

[0062] A heavy metal ion complex stabilizer is composed of the following components by mass percentage: 0.3% sodium sulfide, 2.3% potassium dihydrogen phosphate, 97.4% mushroom slag powder, and the sum of the above mass percentages is 100%.

[0063] Prepare above-mentioned heavy metal ion complex stabilizer, concrete preparation steps are as follows:

[0064] Step 1. Weigh 0.3% of sodium sulfide, 2.3% of potassium dihydrogen phosphate, and 97.4% of shiitake slag powder, and the sum of the above mass percentages is 100%.

[0065] Step 2, sodium sulfide and potassium dihydrogen phosphate taken by weighing in step 1 are respectively configured into sodium sulfide saturated solution and potassium dihydrogen phosphate saturated solution;

[0066] Step 3, slowly mixing the saturated solution of sodium sulfide and the saturated solution of potassium dihydrogen phosphate under stirring conditions to obtain a mixed solution;

[0067] Step 4. Slowly add the mixed solution to the mushro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com