High-entropy alloy component and manufacturing method thereof

A technology of high-entropy alloy and production method, applied in the field of high-entropy alloy, can solve the problems of segregation, inability to solve the composition of high-entropy alloy, etc., and achieve the effects of small grain size, avoiding component segregation, and high tissue density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The manufacturing method of the high-entropy alloy member provided in this embodiment is specifically as follows:

[0065] The first step is to provide LM-X150A equipment from Tianjin Raiming Laser Technology Co., Ltd., vacuumize, fill with argon, and preheat the substrate to 80°C.

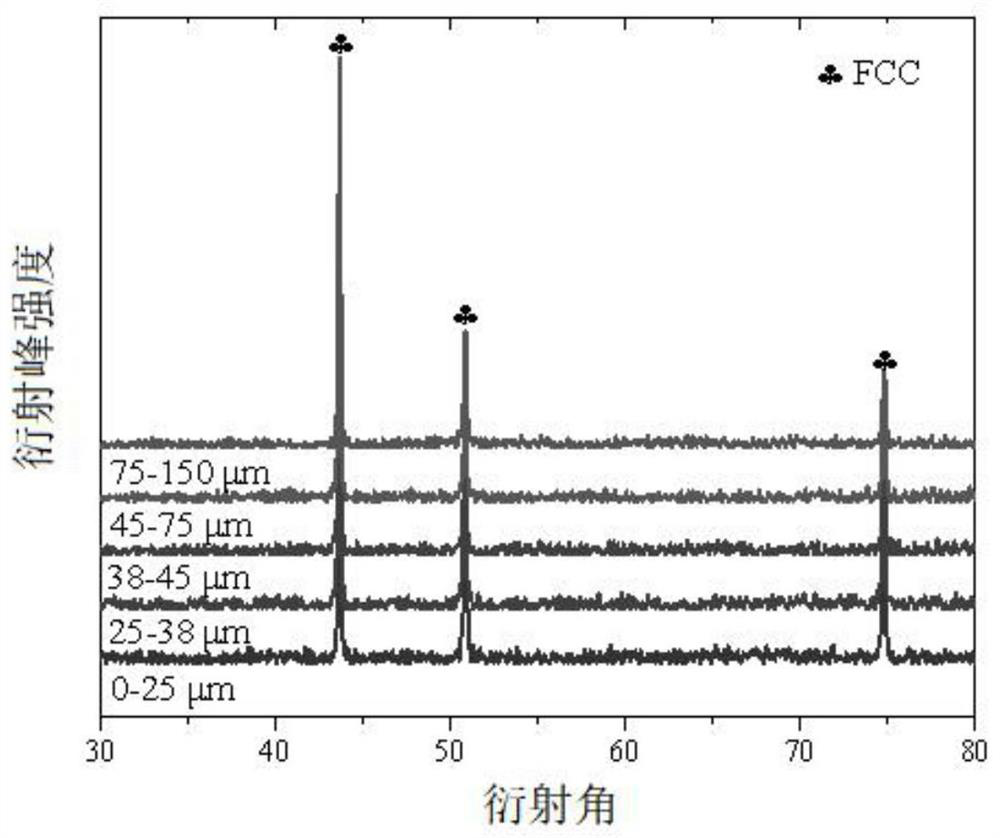

[0066] In the second step, the metal powder is mixed with a planetary ball mill and dried in a vacuum drying oven. The metal powder includes Al, Co, Cr, Fe, and Ni in an atomic ratio of 0.3:1:1:1:1. The particle size of the metal powder is 25 μm to 38 μm.

[0067] The rotational speed of the planetary ball mill is 100r / min, and the time for the planetary ball mill to mix metal powder is 1h. The temperature of the drying treatment is 60° C., and the time of the drying treatment is 4 hours.

[0068] In the third step, the metal powder is loaded into the powder bin of the LM-X150A equipment, and the metal powder is laid on the substrate.

[0069] In the fourth step, the laser is used to se...

Embodiment 2

[0074] The manufacturing method of the high-entropy alloy member provided in this embodiment is specifically as follows:

[0075] The first step is to provide LM-X150A equipment from Tianjin Raiming Laser Technology Co., Ltd., vacuumize, fill with argon, and preheat the substrate to 200°C.

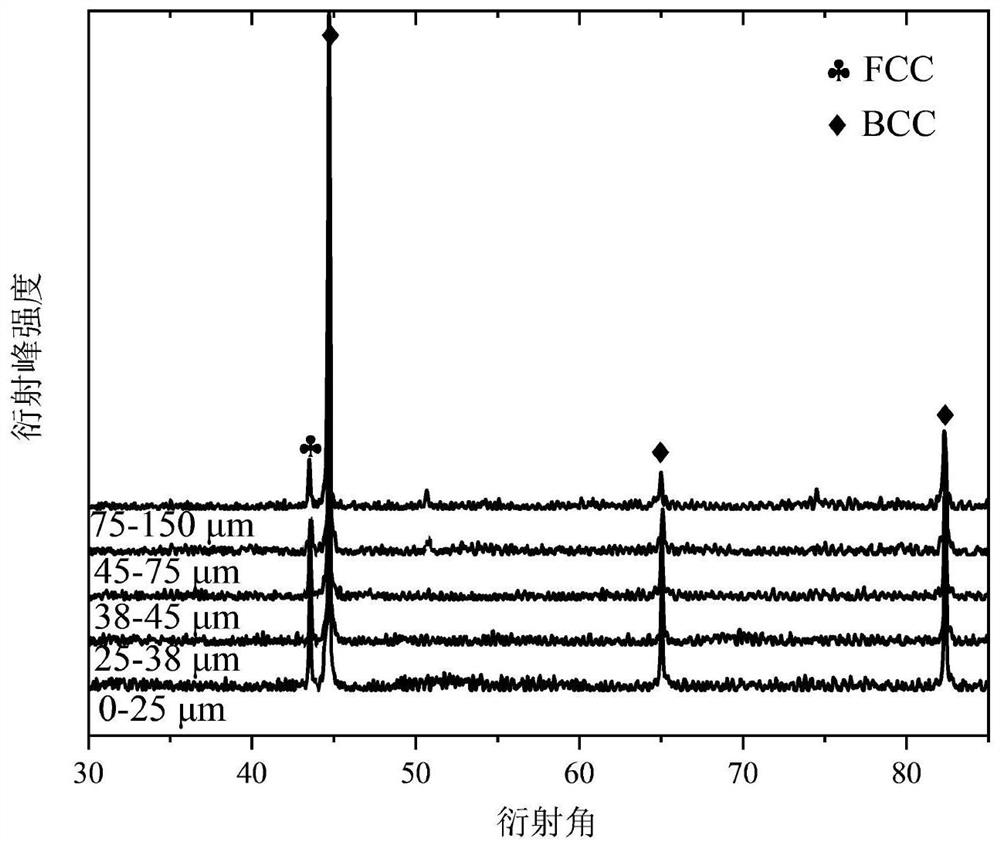

[0076] In the second step, the metal powder is mixed with a planetary ball mill and dried in a vacuum drying oven. The metal powder includes Al, Co, Cr, Fe, and Ni in an atomic ratio of 1.2:1:1:1:1. The particle size of the metal powder is 75 μm to 100 μm.

[0077] The rotational speed of the planetary ball mill is 400r / min, and the time for the planetary ball mill to mix metal powder is 3h. The temperature of the drying treatment is 80° C., and the time of the drying treatment is 8 hours.

[0078] In the third step, the metal powder is loaded into the powder bin of the LM-X150A equipment, and the metal powder is laid on the substrate.

[0079] In the fourth step, the laser is used to ...

Embodiment 3

[0083] The manufacturing method of the high-entropy alloy member provided in this embodiment is specifically as follows:

[0084] The first step is to provide LM-X150A equipment from Tianjin Raiming Laser Technology Co., Ltd., vacuumize, fill with argon, and preheat the substrate to 140°C.

[0085] In the second step, the metal powder is mixed with a planetary ball mill and dried in a vacuum drying oven. The metal powder includes Al, Co, Cr, Fe, and Ni in an atomic ratio of 0.6:1:1:1:1. The particle size of the metal powder is 45 μm to 75 μm.

[0086] The rotational speed of the planetary ball mill is 300r / min, and the time for the planetary ball mill to mix metal powder is 2h. The temperature of the drying treatment is 70° C., and the time of the drying treatment is 5 hours.

[0087] In the third step, the metal powder is loaded into the powder bin of the LM-X150A equipment, and the metal powder is laid on the substrate.

[0088] In the fourth step, the laser is used to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com