Modified attapulgite/sodium alginate/polyvinyl alcohol composite adsorbent as well as preparation method and application thereof

A technology for modifying attapulgite and sodium alginate, which is applied to chemical instruments and methods, and other chemical processes, and can solve the problems of low reuse rate and low adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

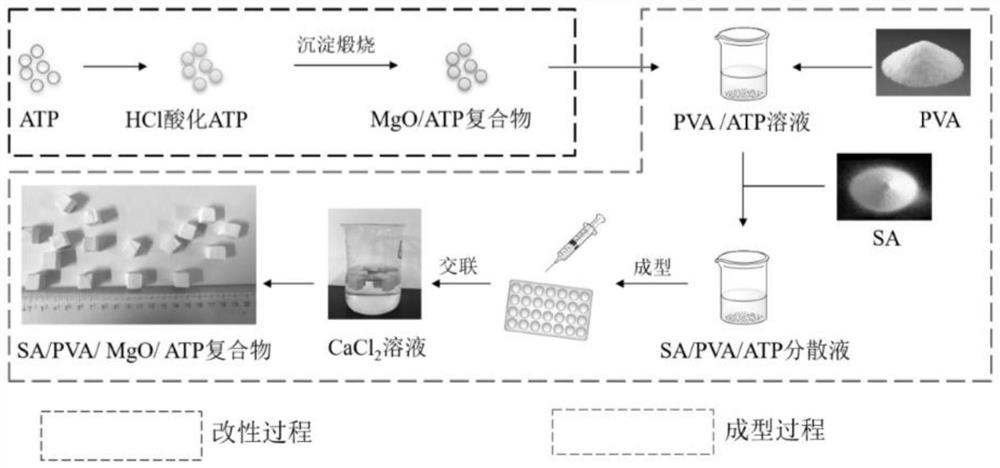

[0023] The invention provides a method for preparing a modified attapulgite / sodium alginate / polyvinyl alcohol composite adsorbent, comprising the following steps:

[0024] (1) attapulgite and hydrochloric acid solution are mixed to carry out acid modification, obtain acid-modified attapulgite;

[0025] (2) The acid-modified attapulgite obtained in the step (1) is mixed with water, magnesium sulfate solution and ammonia water successively, and a metathesis reaction is carried out to obtain a precursor; the precursor is calcined to obtain magnesium oxide / attapulgite composite materials;

[0026] (3) The magnesium oxide / attapulgite composite material obtained in the step (2) is mixed with water, polyvinyl alcohol and sodium alginate to obtain a mixed solution; the mixed solution is sequentially formed and solidified to obtain a modified attapulgite Soil / sodium alginate / polyvinyl alcohol composite adsorbent.

[0027] The invention mixes attapulgite with hydrochloric acid solutio...

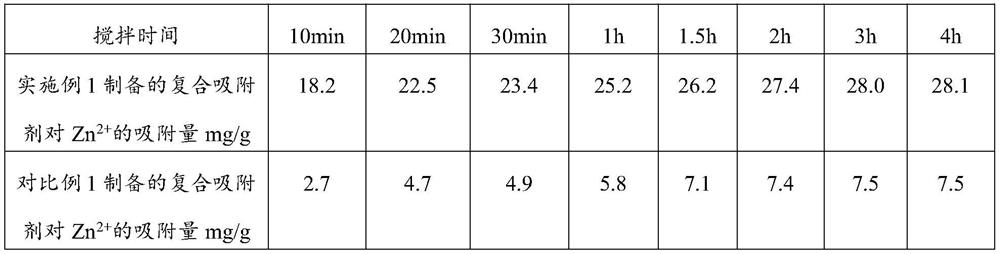

Embodiment 1

[0060] (1) Mix 5 g of ATP with a particle size of 150 μm and 75 mL of a hydrochloric acid solution with a concentration of 1 mol / L, place the resulting mixture in a shaker, shake at a speed of 180 rpm for 60 min, and then centrifuge at a speed of 4000 rpm for 20 min The precipitate obtained by centrifugation was washed three times with deionized water, and the washed precipitate was placed in an oven at 75° C. for 24 hours, and then the dried solid was passed through a 100-mesh sieve to obtain acid-modified ATP.

[0061] (2) the acid-modified ATP that 5g step (1) obtains and 200mL deionized water and 12mL concentration are that the magnesium sulfate solution that 100g / L obtains is placed in the shaker, shakes 15min under the speed of 150rpm, To form a suspension, add 10 mL of 28% ammonia water to the suspension, and shake at a rate of 180 rpm for 45 minutes; separate the solid product from the shaken product under centrifugation at 4000 rpm, and wash the solid product with deio...

Embodiment 2

[0064] (1) Mix 5 g of ATP with a particle size of 100 μm and 50 mL of hydrochloric acid solution with a concentration of 0.5 mol / L, place the resulting mixture in a shaker, shake at a speed of 150 rpm for 45 min, and then centrifuge at a speed of 4500 rpm 20 min; the precipitate obtained by centrifugation was washed 3 times with deionized water, and the washed precipitate was placed in an oven at 70°C for 24 hours, and then the dried solid was passed through a 100-mesh sieve to obtain acid-modified ATP.

[0065] (2) The mixed solution obtained by the acid-modified ATP obtained in 5g step (1) and 200mL deionized water and 10mL concentration is that the magnesium sulfate solution of 110g / L is placed in a shaker, and shaken at a speed of 150rpm for 20min, To form a suspension, add 12mL of 28% ammonia water to the suspension, shake at a rate of 150rpm for 30min; separate the solid product from the shaken product under centrifugation at 4500rpm, and wash the solid product fully with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com