Core-shell composite nanomaterial with hollow silicon sphere as shell and nanometer metal oxide as core, and its preparation method and application

A composite nanomaterial and nanometal technology, which is applied in the field of new shell-core composite nanomaterials to achieve the effects of large potential, high catalytic activity and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

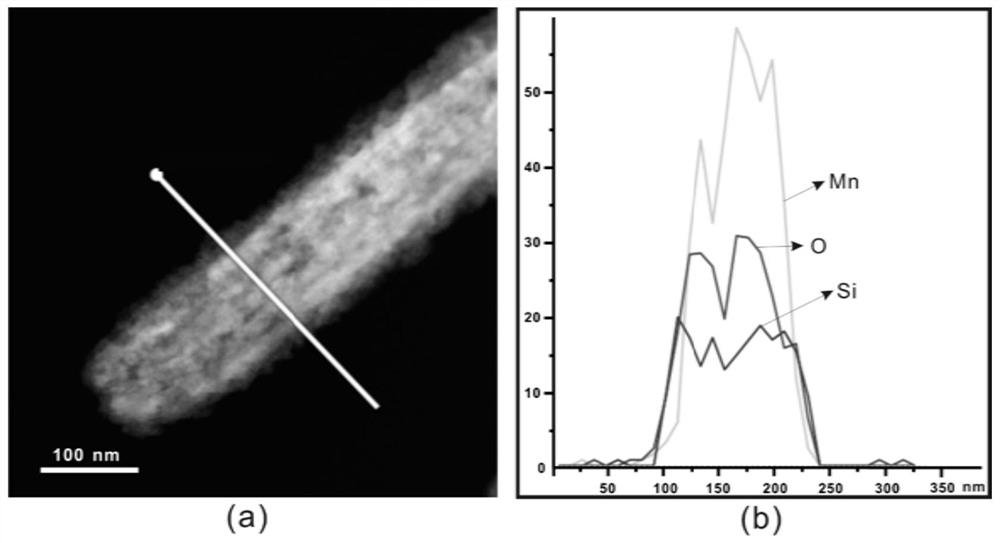

[0042] In step (1), at 20°C, 0.3g of oxide Mn 3 o 4 The nanorods were placed in a reaction vessel filled with 30mL of ethanol, and ultrasonicated for 10min until the oxide Mn 3 o 4 Disperse completely to obtain black emulsion A;

[0043] Step (2), at 20°C, dissolve 30wt% ammonia water in black emulsion A so that the concentration of ammonia water is 20mM, and sonicate for 10min to obtain black emulsion B;

[0044] Step (3), at 20°C, under stirring conditions, dissolve the tetraethyl orthosilicate solution in ethanol to form a transparent solution C;

[0045] Step (4), at 20°C, under stirring conditions, add the C solution dropwise to the B solution to form a suspension D, wherein the atomic ratio of the Si element to the Mn element in the suspension is 0.4:1 ;

[0046] Step (5), after stirring the above mixture D for 6 hours, centrifuge, wash with deionized water and absolute ethanol successively, after each washing 4 times, place the obtained product in an oven at 80°C f...

Embodiment 2

[0052] Change the concentration of ammonia water in step (2) in Example 1 to 100mM, and the others are the same as in Example 1, and finally prepare the dry hollow silicon sphere layer as the shell and the core-shell composite nanomaterial SiO with the rod-shaped oxide as the core. 2 @Mn 3 o 4 -0.4.

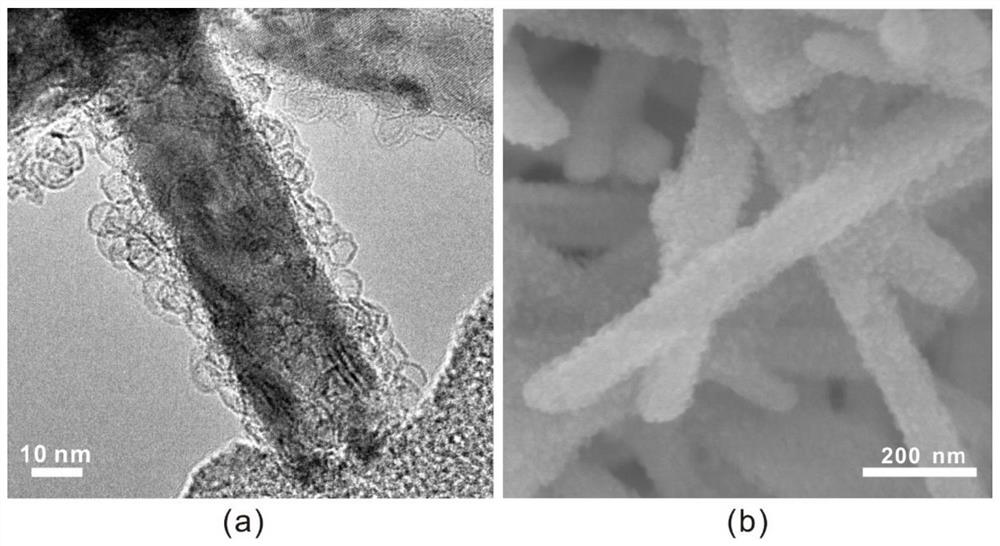

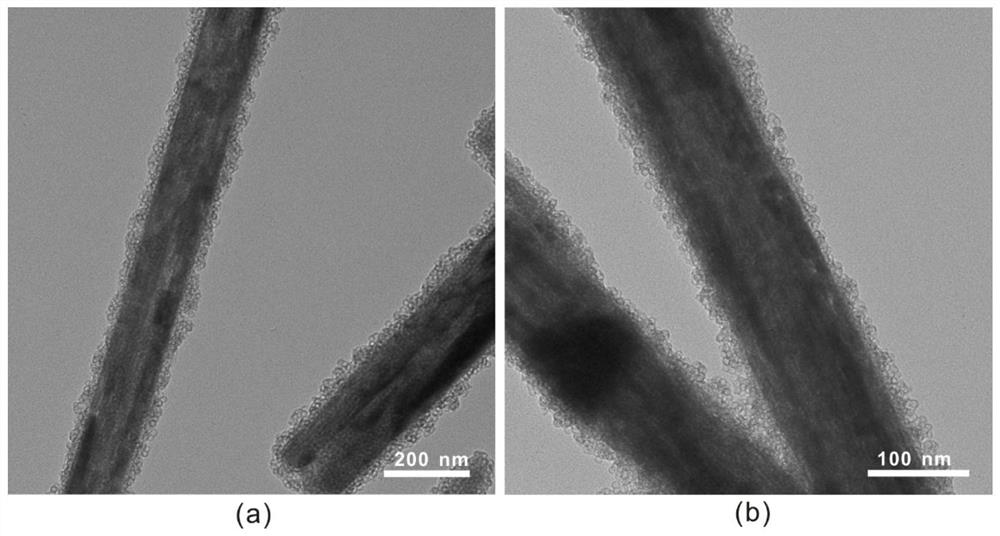

[0053] image 3 (a) is the prepared SiO of embodiment 2 2 @Mn 3 o 4 Common TEM image of -0.4 core-shell composite nanomaterials, showing SiO 2 @Mn 3 o 4 -0.4 The microstructure is a regular rod, and its internal Mn 3 o 4 The nanorod is the core, and the outer hollow silicon sphere layer is the shell.

Embodiment 3

[0055] Change tetraethylammonium hydroxide into tetrapropylammonium hydroxide in step (5) in Example 1, and others are the same as Example 1, and finally prepare the dry hollow silicon sphere layer as the shell and the rod-shaped oxide as the core. Core-shell composite nanomaterial SiO 2 @Mn 3 o 4 -0.4.

[0056] image 3 (b) is the prepared SiO of embodiment 3 2 @Mn 3 o 4 Common TEM image of -0.4 core-shell composite nanomaterials, showing SiO 2 @Mn 3 o 4 -0.4 The microstructure is a regular rod, and its internal Mn 3 o 4 The nanorod is the core, and the outer hollow silicon sphere layer is the shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com