A method for efficiently producing benzaldehyde by catalyzing benzyl alcohol with air in an alkali-free aqueous phase system at room temperature as an oxidant

An oxidant, benzyl alcohol technology, applied in catalyst activation/preparation, heterogeneous catalyst chemical elements, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as low selectivity, achieve simple reaction process, The effect of efficient conversion and high application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

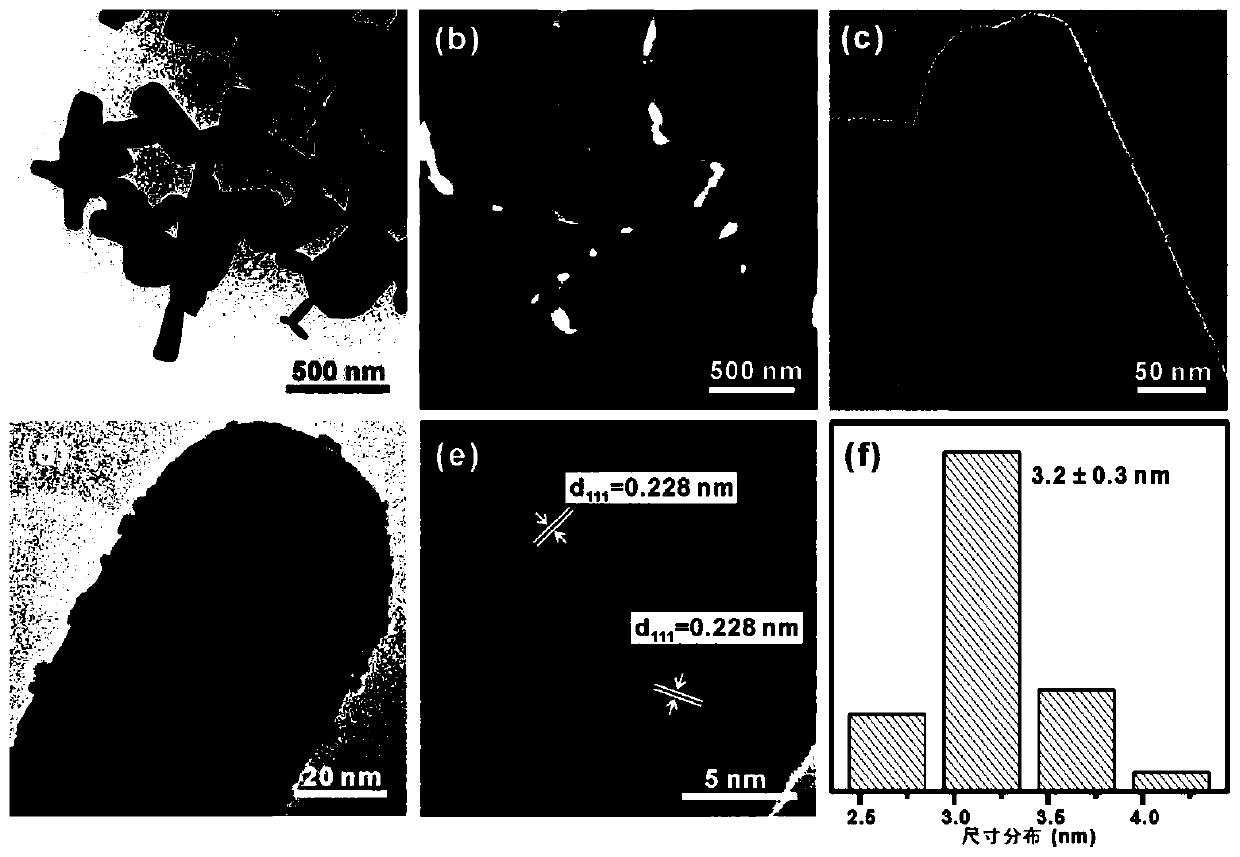

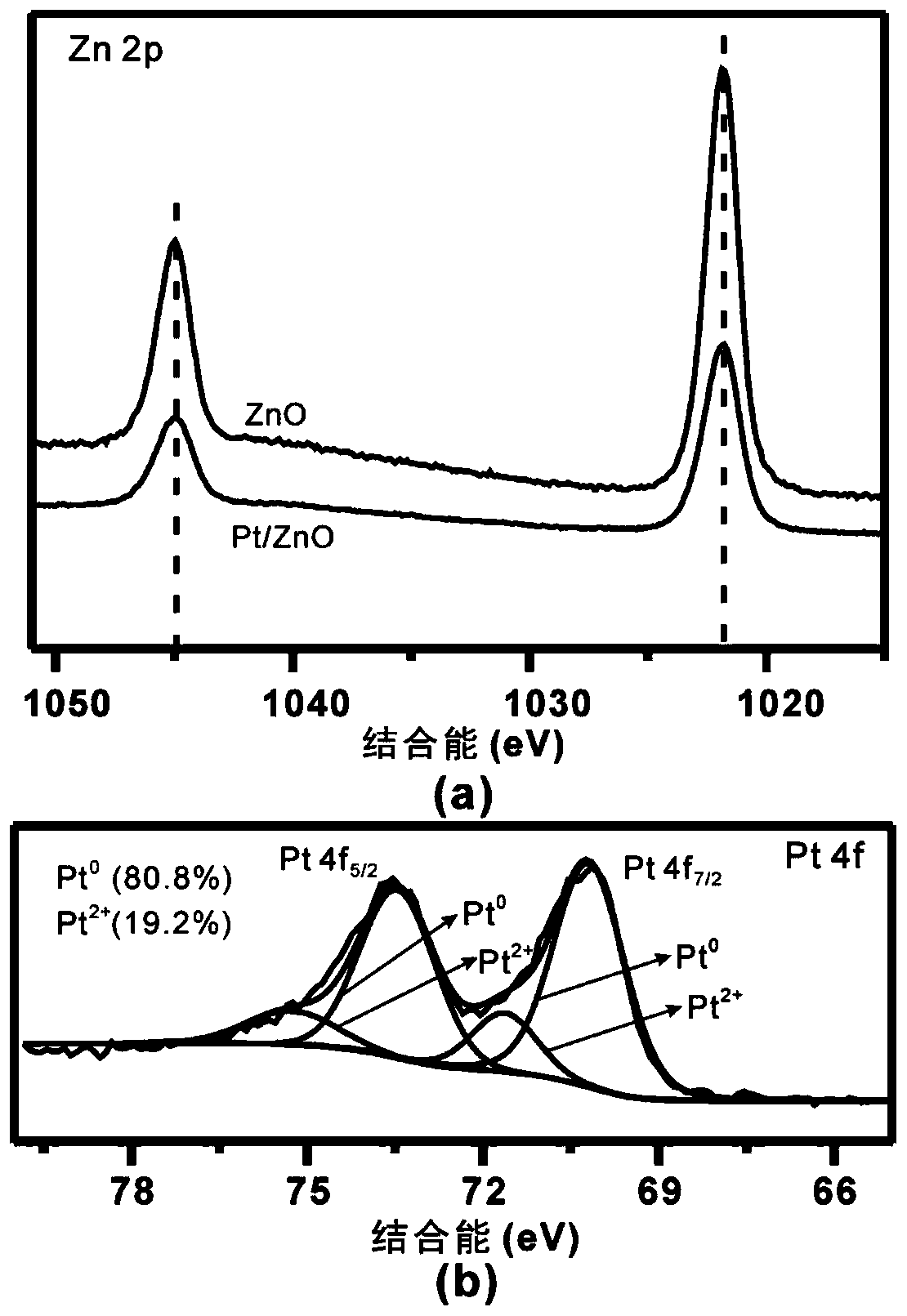

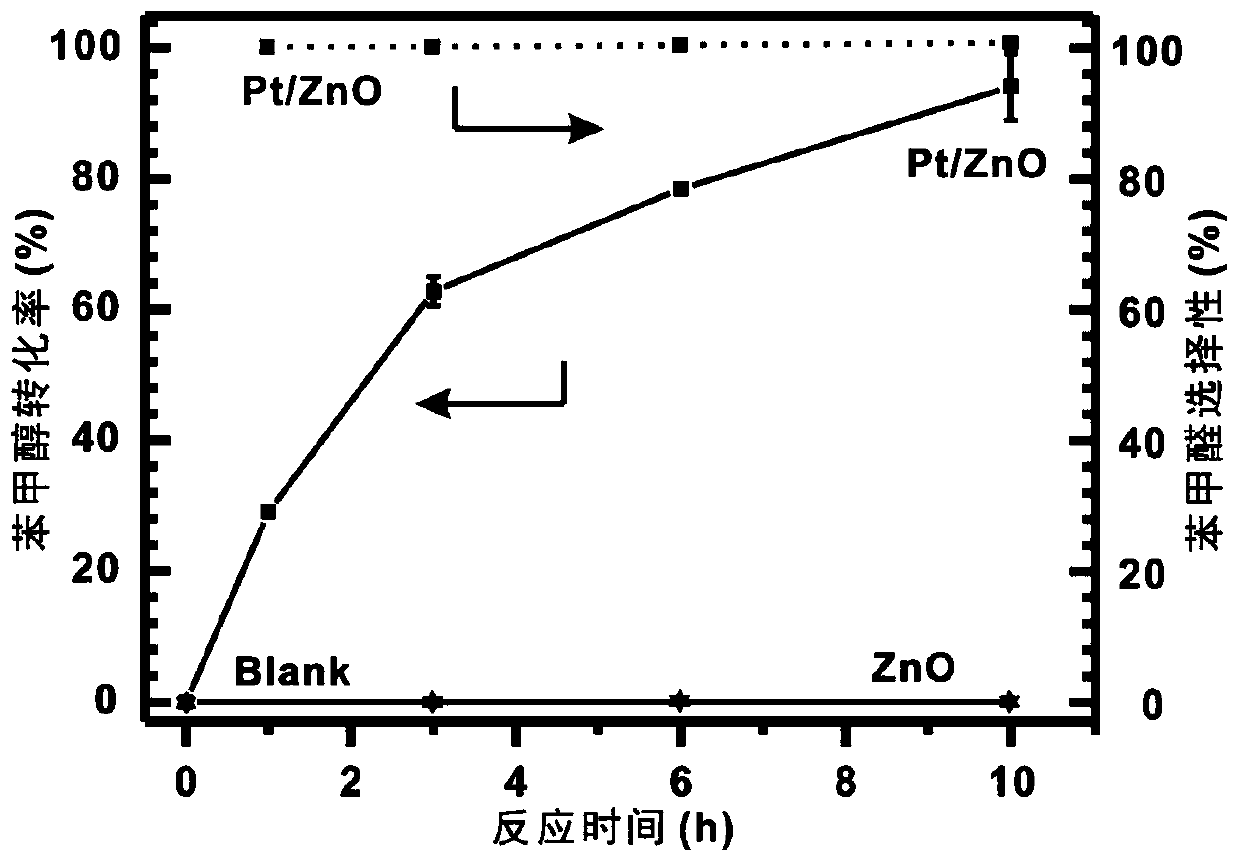

[0035] (1) Dissolve chloroplatinic acid hexahydrate in deionized water so that the concentration of the Pt element is 19.2 mM, and sonicate for 5 minutes until the soluble Pt salt is completely dissolved to obtain a yellow transparent solution A;

[0036] (2) Disperse 0.5g ZnO into 10mL deionized water, and ultrasonically disperse the metal oxide for 5min to obtain suspension B;

[0037] (3) Under stirring conditions, add 1.66mL of A solution into B to obtain light yellow mixture C, the mass ratio of Pt element to ZnO is 1:100;

[0038] (4) Dissolve 30 mg of sodium borohydride in 6 mL of ice water, and ultrasonicate for 5 min to form a colorless and transparent solution D;

[0039] (5) After the above mixture C was stirred for 1 hour, solution D was slowly added dropwise to it, so that the molar ratio of the Pt element in mixture C to the sodium borohydride added dropwise was 1:5, and a gray-brown suspension emulsion E was obtained. ;

[0040] (6) After the suspension emulsi...

Embodiment 2

[0043] (1) Dissolve chloroplatinic acid hexahydrate in deionized water so that the concentration of the Pt element is 19.2 mM, and sonicate for 5 minutes until the soluble Pt salt is completely dissolved to obtain a yellow transparent solution A;

[0044] (2) Disperse 0.5g ZnO into 10mL deionized water, and ultrasonically disperse the metal oxide for 5min to obtain suspension B;

[0045] (3) Under stirring conditions, add 1.66mL of A solution into B to obtain light yellow mixture C, the mass ratio of Pt element to ZnO is 1:100;

[0046] (4) Dissolve 30 mg of sodium borohydride in 10 mL of ice water, and ultrasonicate for 5 minutes to form a colorless and transparent solution D;

[0047] (5) After the above mixture C was stirred for 1 hour, solution D was slowly added dropwise to it, so that the molar ratio of the Pt element in mixture C to the sodium borohydride added dropwise was 1:5, and a gray-brown suspension emulsion E was obtained. ;

[0048] (6) After the suspension e...

Embodiment 3

[0051] (1) Dissolve chloroplatinic acid hexahydrate in deionized water so that the concentration of the Pt element is 19.2 mM, and sonicate for 5 minutes until the soluble Pt salt is completely dissolved to obtain a yellow transparent solution A;

[0052] (2) Disperse 0.5g ZnO into 10mL deionized water, and ultrasonically disperse the metal oxide for 5min to obtain suspension B;

[0053] (3) Under stirring conditions, add 1.66mL of A solution into B to obtain light yellow mixture C, the mass ratio of Pt element to ZnO is 1:100;

[0054] (4) Dissolve 30 mg of sodium borohydride in 6 mL of ice water, and ultrasonicate for 5 min to form a colorless and transparent solution D;

[0055] (5) After the above mixture C was stirred for 1 hour, solution D was slowly added dropwise to it, so that the molar ratio of the Pt element in mixture C to the sodium borohydride added dropwise was 1:5, and a gray-brown suspension emulsion E was obtained. ;

[0056] (6) After the suspension emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com