Method for hot dipping of composite zinc coating on surface of steel and steel coating composite material

A technology of steel surface and zinc coating, applied in hot-dip coating process, metal material coating process, coating, etc., can solve the problems of increased zinc consumption, ineffective solution, complex composition, etc., and achieve the effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

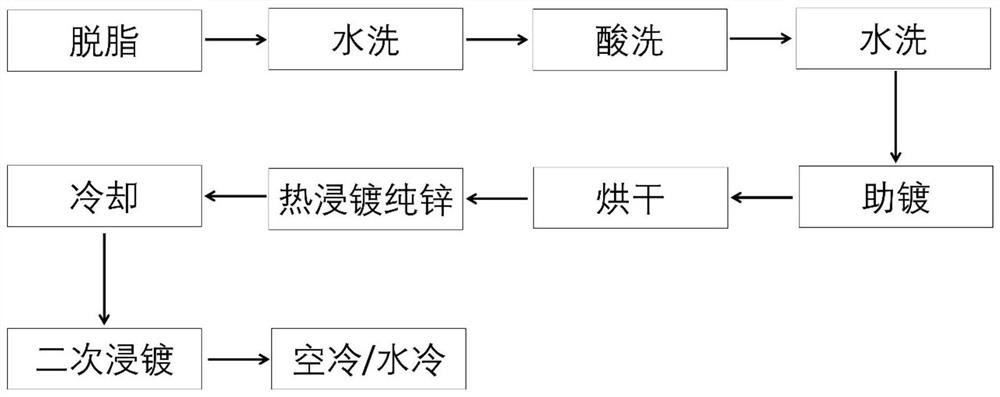

[0043] This embodiment provides a method for hot-dipping composite zinc coating on steel surface, which adopts figure 1 The process steps in the preparation of high corrosion resistance Zn-3Al alloy coating, the process is degreasing→water washing→pickling→water washing→plating help→drying→hot-dip pure zinc plating→cooling→hot-dip Zn-3Al alloy→cooling . details as follows:

[0044] (1) Place the low-silicon steel sheet (5cm×4cm×3mm) in NaOH solution (concentration: 20wt%) to degrease for 2min, the degreasing temperature is 70°C, and rinse with water after degreasing.

[0045] (2) Place the low-silicon steel sheet rinsed in step (1) in hydrochloric acid with a concentration of 15wt% for 5 minutes to pickle and remove rust, and rinse with water after rust removal.

[0046] (3) Soak the low-silicon steel test piece rinsed in step (2) in a 70°C fluxing solution (100g / L NH 4 Cl, 90g / LZnCl 2 , and the rest is water) for 2 minutes, take it out and dry it.

[0047] (4) Soak the l...

Embodiment 2

[0051] This embodiment provides a method for hot-dipping composite zinc coating on steel surface, which adopts figure 1 The process steps in the preparation of high corrosion resistance Zn-7Al alloy coating, the process is degreasing→water washing→pickling→water washing→plating help→drying→hot-dip pure zinc plating→cooling→hot-dip Zn-7Al alloy→cooling . details as follows:

[0052] (1) Place the low-silicon steel sheet (5cm×4cm×3mm) in NaOH solution (concentration: 20wt%) to degrease for 2min, the degreasing temperature is 70°C, and rinse with water after degreasing.

[0053] (2) Place the low-silicon steel sheet rinsed in step (1) in hydrochloric acid with a concentration of 15wt% for 5 minutes to pickle and remove rust, and rinse with water after rust removal.

[0054] (3) Soak the low-silicon steel test piece rinsed in step (2) in a 70°C fluxing solution (100g / L NH 4 Cl, 90g / LZnCl 2 , and the rest is water) for 2 minutes, take it out and dry it.

[0055] (4) Soak the l...

Embodiment 3

[0059] This embodiment provides a method for hot-dipping composite zinc coating on steel surface, which adopts figure 1 The process steps in the preparation of high corrosion resistance Zn-5Al alloy coating, the process is degreasing→water washing→pickling→water washing→plating help→drying→hot-dip pure zinc plating→cooling→hot-dip Zn-5Al alloy→cooling . details as follows:

[0060] (1) Place the low-silicon steel sheet (5cm×4cm×3mm) in NaOH solution (concentration: 20wt%) to degrease for 2min, the degreasing temperature is 70°C, and rinse with water after degreasing.

[0061] (2) Place the low-silicon steel sheet rinsed in step (1) in hydrochloric acid with a concentration of 15wt% for 5 minutes to pickle and remove rust, and rinse with water after rust removal.

[0062] (3) Soak the low-silicon steel test piece rinsed in step (2) in a 70°C fluxing solution (100g / L NH 4 Cl, 90g / LZnCl 2 , and the rest is water) for 2 minutes, take it out and dry it.

[0063] (4) Soak the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com