One-bath desizing and dyeing device for polyester fabric containing sizing agent

A technology for dyeing devices and fabrics, which is applied in the processing of textile material equipment configuration, textiles and papermaking, textile processing machine accessories, etc., can solve the problems of washing water damage, sewage, environmental impact, etc., and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

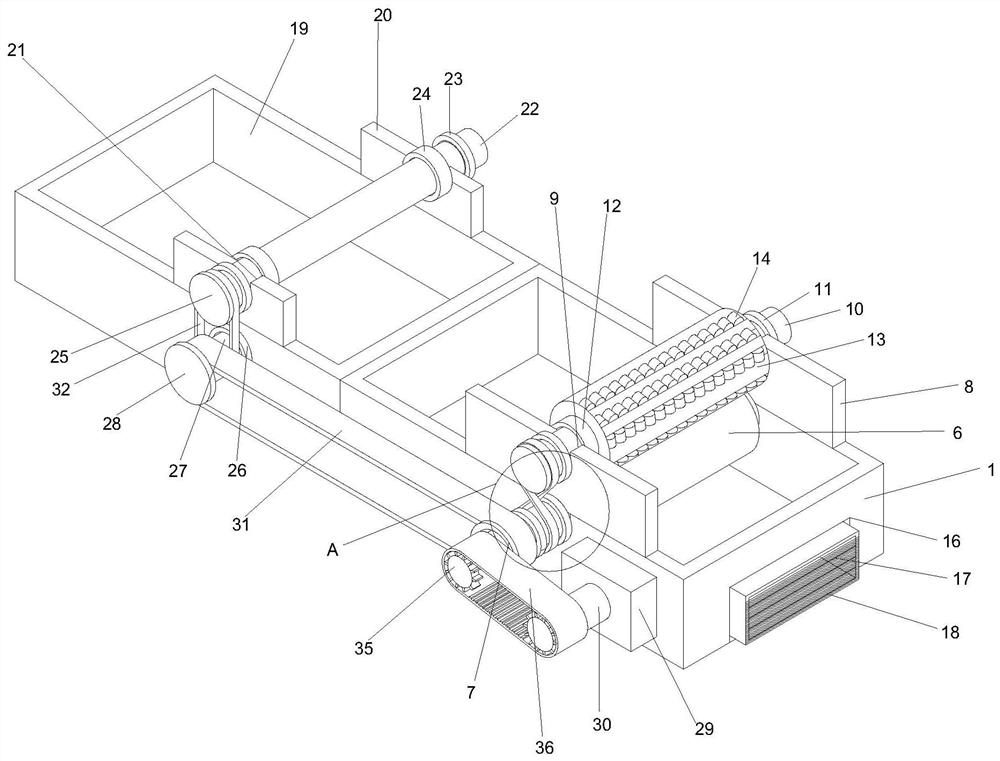

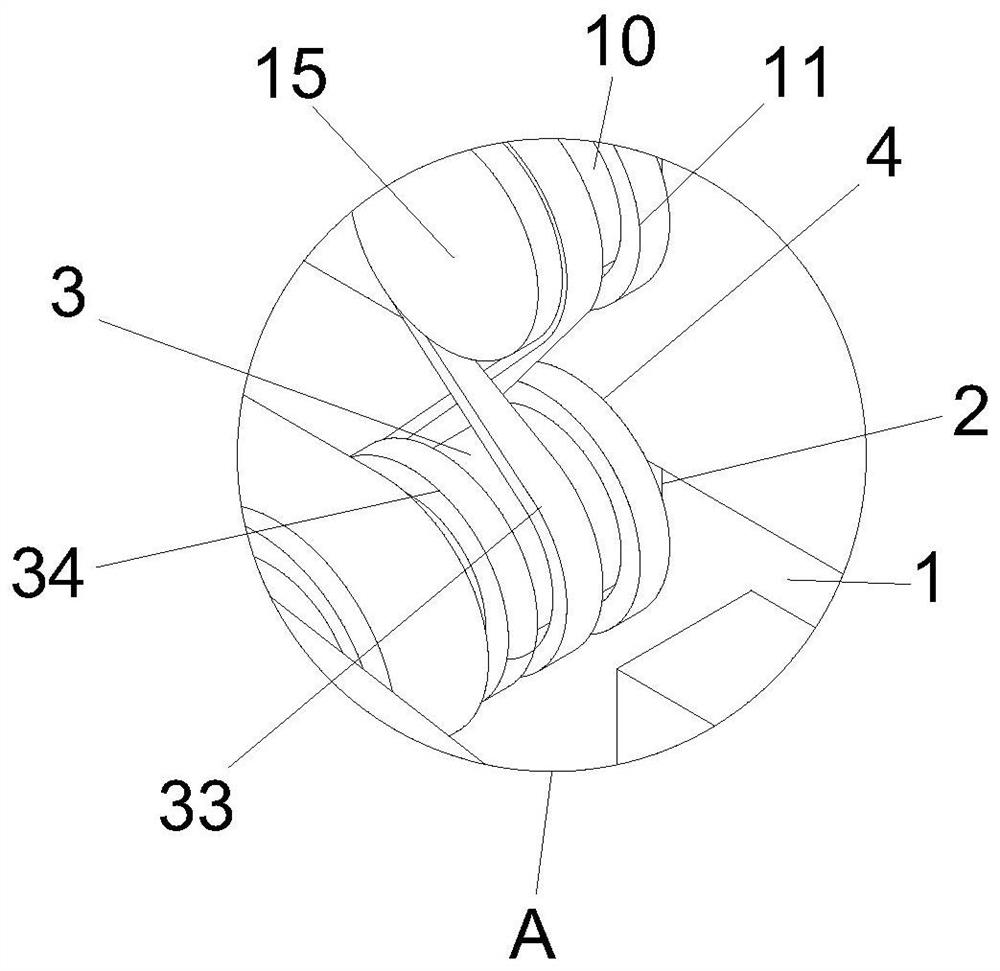

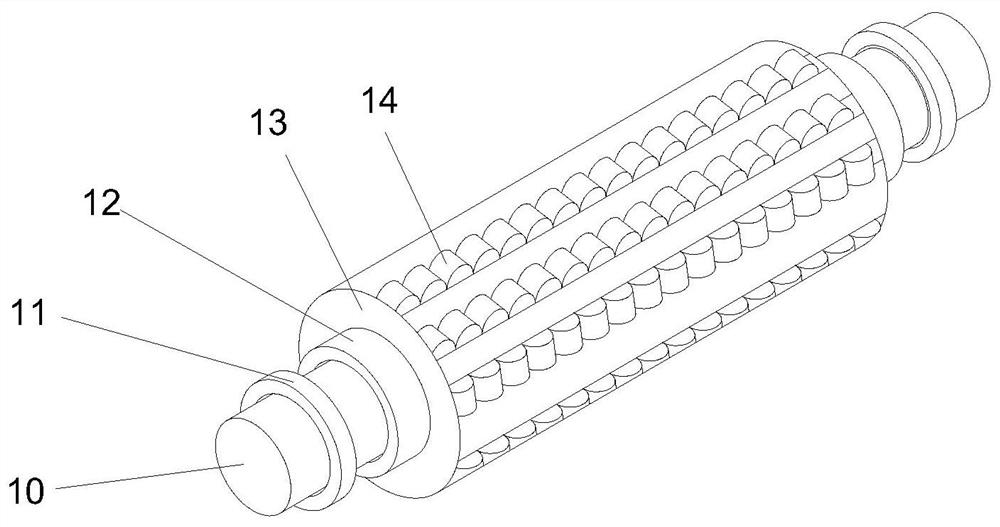

[0026] Embodiment: a kind of one-bath desizing and dyeing device of polyester fiber containing pulp, such as Figure 1-Figure 5 As shown, it includes a pulp receiving tank 1, which is a rectangular pool with a hollow interior and a groove on the top. The left and right sides of the pulp receiving tank 1 are provided with a pulp receiving hole 2 on the side facing away from each other. The slurry hole 2 is a circular through hole, and the inside of the pulp connection hole 2 is movable to install a lower roller shaft 3, which is a cylindrical long rod, and the outer circles of the left and right ends of the lower roller shaft 3 are sleeved with The first gear ring 4, the first gear ring 4 is a ring and the first gear ring 4 is located on the outside of the slurry pool 1, the lower roller shaft 3 runs through the inside of the first gear ring 4 transversely, and the outer part of the lower roller shaft 3 There are two groups of first snap rings 5 fixedly installed in the circl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com