Low-power-consumption high-performance super-junction JBS diode and manufacturing method thereof

A super-junction, high-performance technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult process, unfavorable promotion, high cost, etc., and achieve simple manufacturing process, low manufacturing cost and high durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

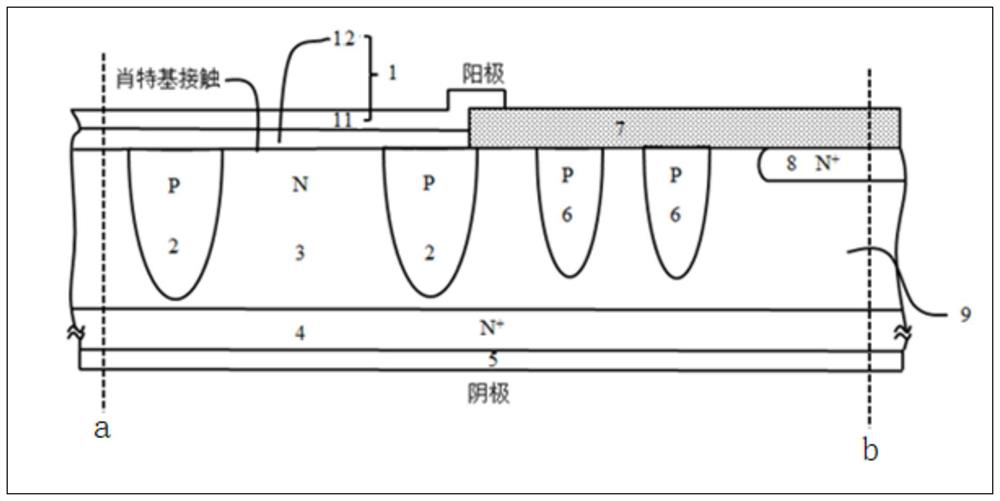

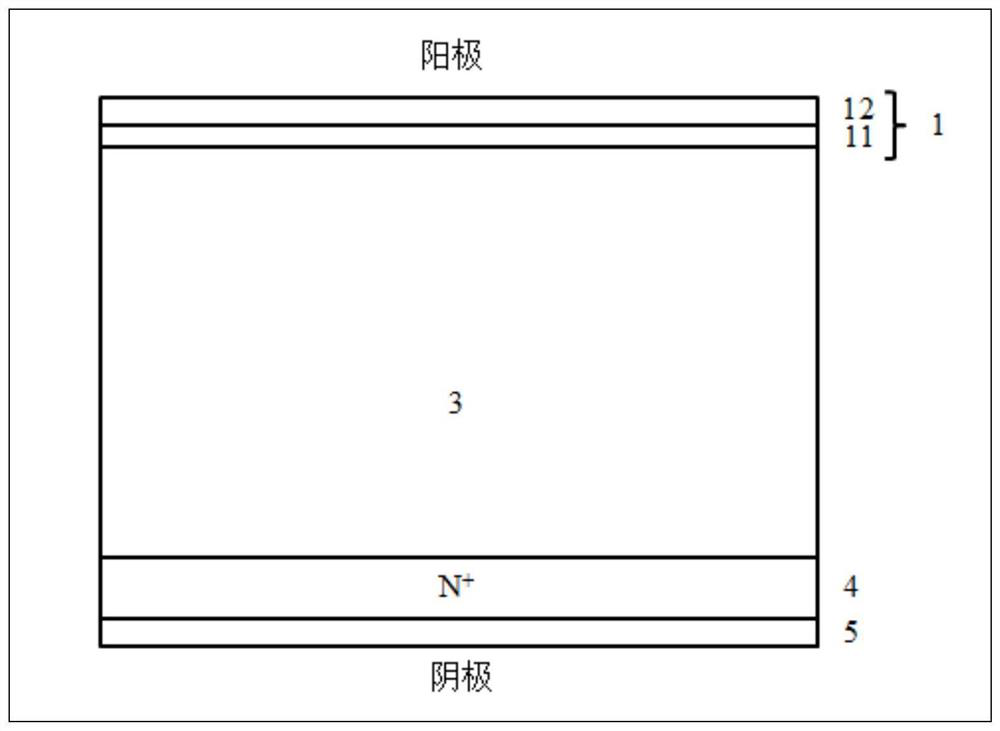

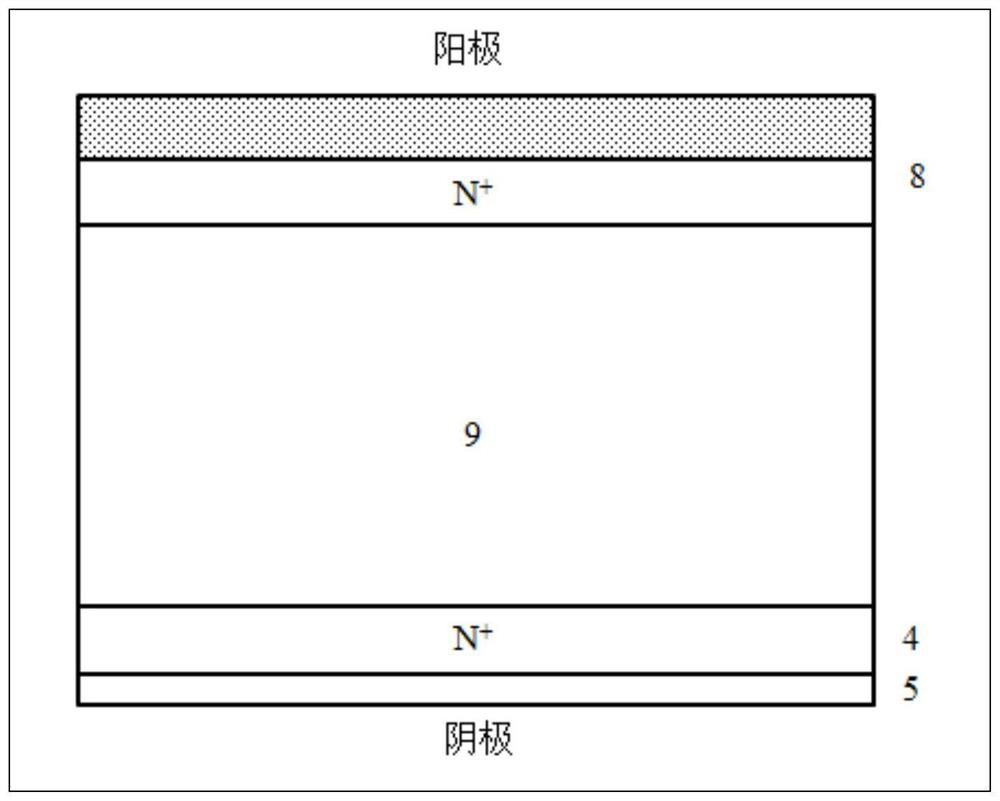

[0054] A low-power-consumption high-performance super-junction JBS diode includes: 1. Anode metal electrode; 11. Metal silicide layer; 12. Metal layer structure; 2. P heavily doped columnar region; 3. N columnar drift region; 4. N+ heavily doped region at the bottom; 5. Cathode metal electrode; 6. P-type field effect ring; 7. Insulation barrier layer; 8. N+ type stop ring; 9. Terminal.

[0055] Low power consumption and high performance super-junction JBS diodes use high-concentration N+ doped silicon wafers as the overall substrate of the device, and this high-concentration wafer becomes the N+ heavily doped region 4 at the bottom of the device after the device is integrally formed. The bottom N+ heavily doped region 4 is connected to the metal electrode by means of ohmic contact, and the metal electrode connected below the bottom N+ heavily doped region 4 is the cathode metal electrode 5 of the device. The function of connecting the cathode electrode can also support the dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com