LED electrodeless color temperature adjusting light source and manufacturing process thereof

A color temperature and light source technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of inability to accurately control the color of the light source, light spot, uneven distribution of light spots, and inability to accurately adjust the color temperature and brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

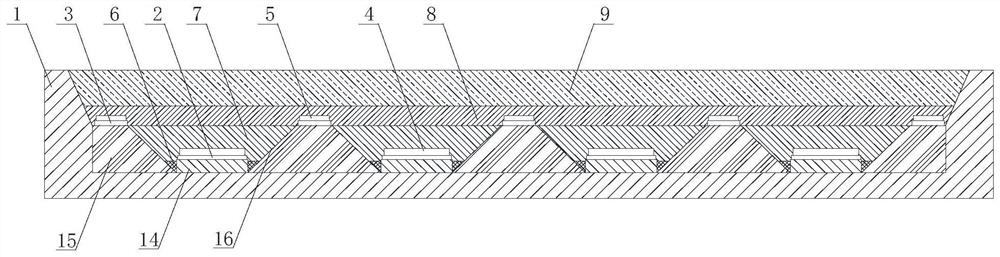

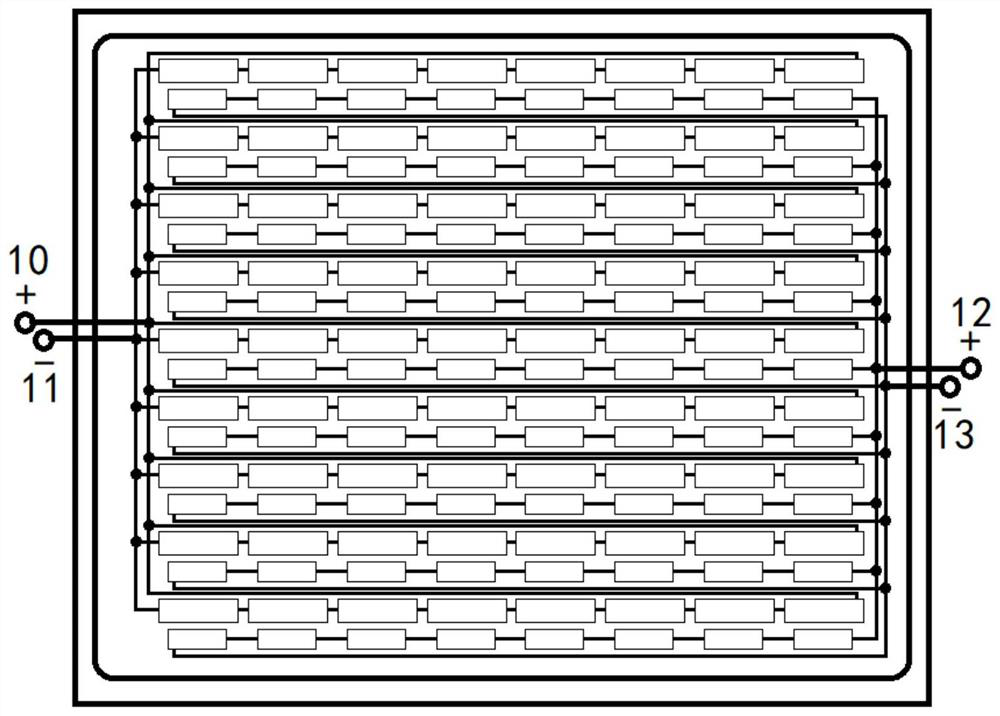

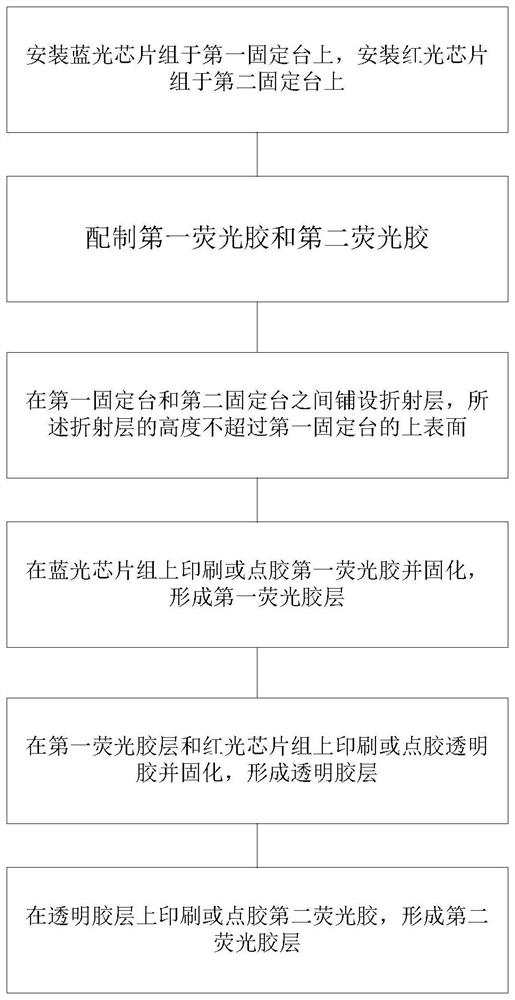

[0054] Such as figure 1The shown LED stepless color temperature light source includes a substrate 1, on which a crystal-bonding area is arranged, and first fixing tables 14 and second fixing tables 15 are arranged alternately in the crystal-bonding area. The fixed platform 14 is provided with a first circuit board 2, the first circuit board 2 is provided with a blue light chipset, the second fixed platform 15 is provided with a second circuit board 3, and the second circuit board 3 is provided with A red chip set is provided; the blue chip set is covered with a first fluorescent adhesive layer 7, and a transparent adhesive layer 8 is arranged on the first fluorescent adhesive layer 7, and the transparent adhesive layer 8 covers the red chip set, the transparent adhesive layer 8 is provided with a second fluorescent adhesive layer 9; both the first fluorescent adhesive layer 7 and the second fluorescent adhesive layer 9 contain yellow phosphor, and the blue light emitted by the...

Embodiment 2

[0061] On the basis of Example 1, in parts by weight, the first fluorescent adhesive layer 7 is composed of 4.2 to 5.3 parts of glue A / B and 0.05 to 0.1 part of yellow fluorescent powder, and the second fluorescent adhesive layer 9 is composed of 4.2 parts. ~5.3 parts of glue A / B and 0.1~0.14 parts of yellow fluorescent powder.

[0062] In this embodiment, the first fluorescent glue layer and the second fluorescent glue layer are only composed of yellow phosphor powder, glue A / B and necessary impurities, which not only simplifies the preparation process of fluorescent glue, reduces the difficulty and cost of the overall process, but also The shallow and deep two excitations completed by the designed component ratio effectively improve the light output efficiency of the light source, and the high and low color temperature fusion effect is better, and the color temperature adjustment is smoother.

[0063] In some embodiments, the content of the yellow phosphor in the second fluo...

Embodiment 3

[0068] On the basis of Example 2, the first fluorescent glue layer 7 is composed of 4.2 parts of glue A / B and 0.07 part of yellow phosphor, and the second fluorescent glue layer 9 is composed of 4.2 parts of glue A / B and 0.14 part of yellow phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color temperature | aaaaa | aaaaa |

| Color temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com