High polymer and preparation and application thereof

A technology of high polymer and aqueous solution polymerization method, which is applied to high polymer and its preparation and its application in corrosion inhibition, can solve the problems of corrosion of metal materials, difficulties in marine development, and large direct economic losses, and achieve corrosion inhibition. Corrosion effect, excellent thermal stability and ion adsorption performance, effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

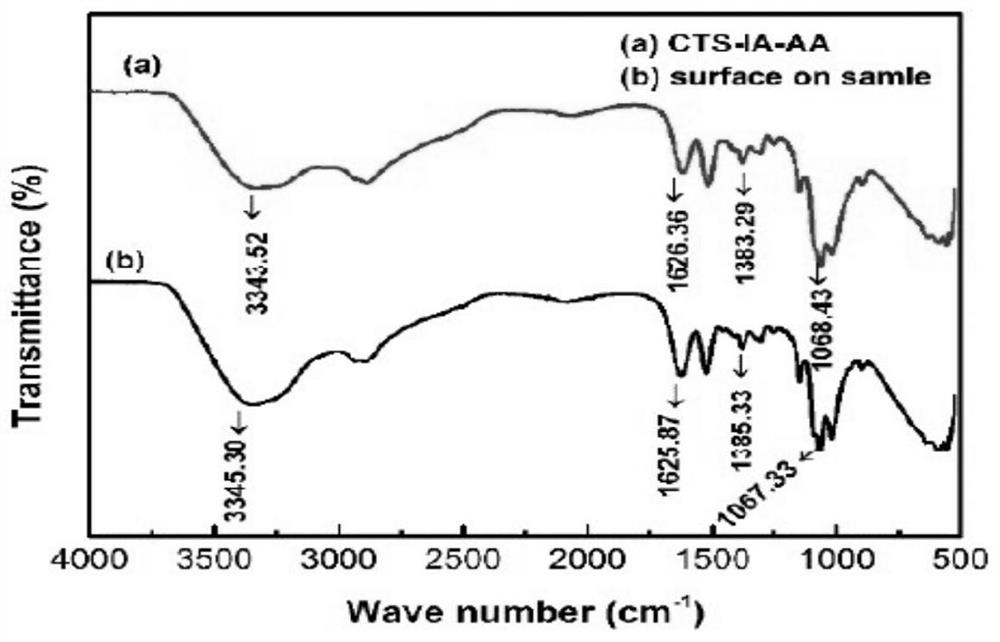

[0042] The preparation of polymer CTS-IA-AA specifically includes the following steps:

[0043] (1) According to the monomer mass ratio CTS:IA:AA=10:7:3, first put CTS into the four-necked flask according to the above dosage, then add IA and AA monomers, quickly add distilled water, and stir with a mixer Evenly, the raw materials are fully dissolved and ready for use;

[0044] (2) Place the four-necked flask in a constant water bath at 40°C and continue to stir, because O 2 It has a polymerization inhibitory effect on the polymerization reaction, so N is introduced into the four-necked flask. 2 Protection reaction, adding EDTA and redox system to the system, the reaction time is 5h; wherein, the final concentration of APS-SBS in the system is 15wt%, the mass ratio of APS and SBS is 1:1; the mass ratio of EDTA and CTS in the system is 2:1.

[0045] (3) The product of the polymerization reaction is taken out from the four-necked flask, and absolute ethanol is added to precipi...

Embodiment 2

[0049] The preparation of polymer CTS-IA-AA specifically includes the following steps:

[0050] (1) According to the monomer mass ratio CTS:IA:AA=11:6:3, first put CTS into the four-necked flask according to the above dosage, then add IA and AA monomers, quickly add distilled water, and stir with a mixer Evenly, the raw materials are fully dissolved and ready for use;

[0051] (2) Place the four-necked flask in a constant water bath at 30°C and continue to stir, because O 2 It has a polymerization inhibitory effect on the polymerization reaction, so N is introduced into the four-necked flask. 2 Protection reaction, adding EDTA and redox system to the system, the reaction time is 4h; wherein, the final concentration of APS-SBS in the system is 12wt%, the mass ratio of APS and SBS is 2:1; the mass ratio of EDTA and CTS in the system is 2:1.

[0052] (3) The product of the polymerization reaction is taken out from the four-necked flask, and absolute ethanol is added to precipi...

Embodiment 3

[0055] The preparation of polymer CTS-IA-AA specifically includes the following steps:

[0056] (1) According to the monomer mass ratio CTS:IA:AA=6:10:4, first put CTS into the four-necked flask according to the above dosage, then add IA and AA monomers, quickly add distilled water, and stir with a mixer Evenly, the raw materials are fully dissolved and ready for use;

[0057] (2) Place the four-necked flask in a constant water bath at 50°C and continue to stir, because O 2 It has a polymerization inhibitory effect on the polymerization reaction, so N is introduced into the four-necked flask. 2 Protection reaction, adding EDTA and redox system to the system, the reaction time is 6h; wherein, the final concentration of APS-SBS in the system is 18wt%, the mass ratio of APS and SBS is 1:1; the mass ratio of EDTA and CTS in the system is 2:1.

[0058] (3) The product of the polymerization reaction is taken out from the four-necked flask, and absolute ethanol is added to precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com