Anti-corrosion conductive chemical conversion film-forming liquid for electronic shell, and preparation method of conversion film

A chemical conversion film and chemical conversion technology, which is applied in the field of anti-corrosion and conductive chemical conversion film forming liquid and conversion film preparation of electronic housings, can solve the problems of increased surface contact resistance and reduced conductivity of the conversion film to prevent corrosion , The electrical conductivity does not decrease, and the electrical conductivity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

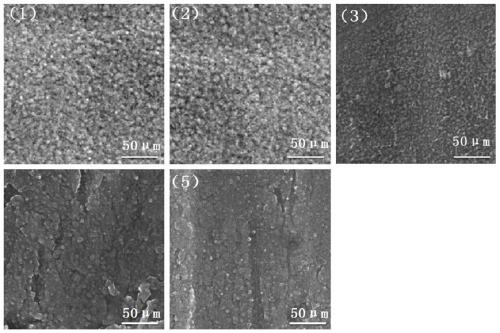

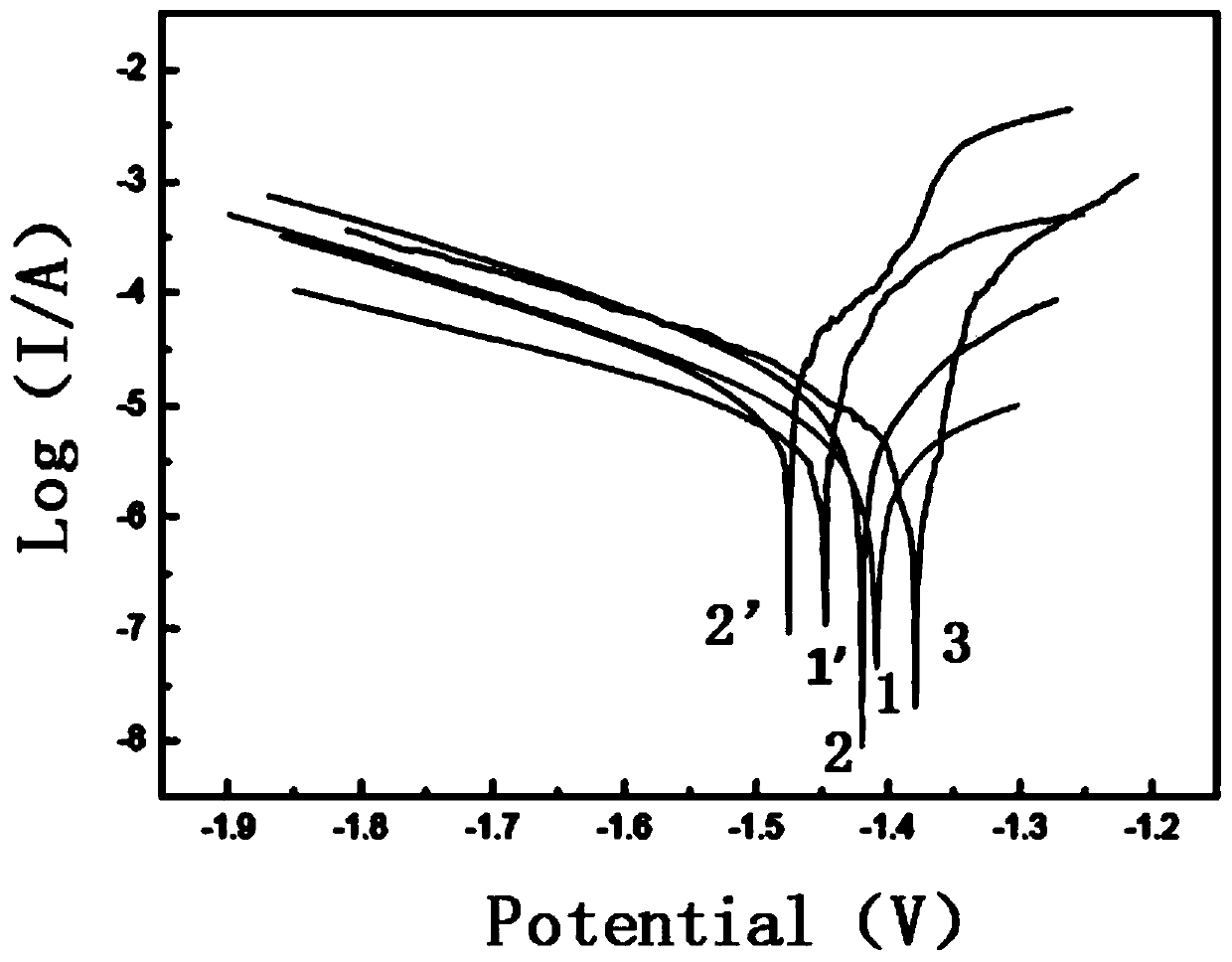

Embodiment 1

[0051] A corrosion-resistant conductive chemical conversion film-forming liquid for an electronic shell, comprising: sodium phosphate 30g / L, sodium stannate 35g / L, sodium permanganate 25g / L, nickel nitrate 0.2g / L, polyamide-amine tree 2 g / L of macromolecules, 17 g / L of phosphoric acid, the balance of water, and the pH of the chemically converted membrane solution was 4.8. The preparation method of the chemical conversion film includes the following steps: (1) sequentially using 500 # , 1000 # , 1500 # Polished with sandpaper, then ultrasonically cleaned with absolute ethanol and water for 10 min.

[0052] (2) Immerse the magnesium alloy electronic shell in a micro-etching solution composed of 10g / L hydrochloric acid, 5g / L ethylene glycol and the balance of water, and slightly etch the surface of the electronic shell to a Ra of 0.21μm, take out the water and wash . The micro-etching temperature was 40°C, and the micro-etching time was 2 min.

[0053] (3) The electron shell...

Embodiment 2

[0057]A corrosion-resistant conductive chemical conversion film-forming solution for electronic housings, including: 35g / L sodium dihydrogen phosphate, 40g / L sodium stannate, 30g / L sodium permanganate, 0.3g / L nickel nitrate, polyamide-amine Dendrimer-like macromolecule 3g / L, nitric acid 20g / L, balance water, and the pH of the chemical conversion film-forming liquid are 4.5. The preparation method of the chemical conversion film comprises the following steps: (1) sequentially using 500 # 、1000 # , 1500 # Polish with sandpaper, then ultrasonically clean with absolute ethanol and water for 15 minutes.

[0058] (2) Soak the magnesium alloy electronic housing in a micro-etching solution composed of 15g / L hydrochloric acid, 6g / L ethylene glycol, and the rest of water, micro-etch the surface of the electronic housing until the Ra is 0.38μm, take it out and wash it with water . The microetching treatment temperature is 35° C., and the microetching treatment time is 4 minutes.

[...

Embodiment 3

[0063] A corrosion-resistant conductive chemical conversion film-forming solution for electronic housings, including: 40g / L potassium phosphate, 45g / L potassium stannate, 35g / L potassium permanganate, 0.4g / L calcium nitrate, polyamide-amine resin 4g / L of macromolecule, 25g / L of nitric acid, surplus water, the pH of described chemical transformation membrane-forming liquid is 4.1. The preparation method of the chemical conversion film comprises the following steps: (1) sequentially using 500 # 、1000 # , 1500 # Polish with sandpaper, then ultrasonically clean with absolute ethanol and water for 20 minutes.

[0064] (2) Soak the magnesium alloy electronic housing in a micro-etching solution composed of 120g / L hydrochloric acid, 10g / L ethylene glycol, and the rest of water, micro-etch the surface of the electronic housing until the Ra is 0.43μm, take it out and wash it with water . The microetching treatment temperature is 55° C., and the microetching treatment time is 4 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com