A kind of preparation method of magnesium alloy surface composite film layer

A surface composite, magnesium alloy technology, applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problems of low density of phosphate film, weakened corrosion resistance, etc., to meet the requirements of environmental protection and reliability Effects of continuous development, short production times, improved surface quality and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

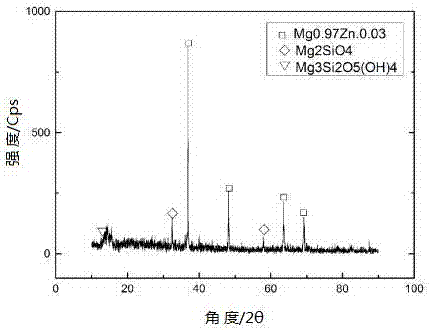

Image

Examples

Embodiment 1

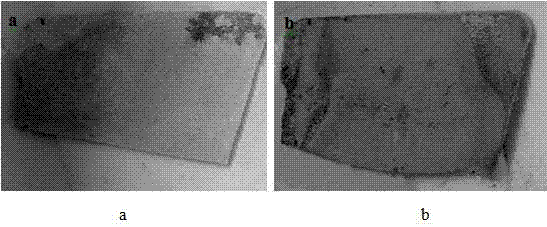

[0023] Example 1. The material is the shell of the hand electric drill head.

[0024] Grind and load the shell of the electric drill head.

[0025] Degreasing: Immerse the shell in a sodium hydroxide degreasing tank with a mass percentage of 8% and a temperature of 75°C, and use ultrasonic waves for 20 minutes to make the oil, alkaline solution and surface active substances undergo saponification and emulsification reactions and dissolve in the In water, in order to achieve the purpose of degreasing, it can be clearly seen that the surface of the shell becomes bright. Afterwards, enter the first distilled water washing tank, apply ultrasonic waves at room temperature for 40 seconds, remove the alkaline solution and grease molecules remaining on the surface of the shell, take it out and dry it with hot air.

[0026] Pickling: Then immerse the casing in a pickling tank filled with 50g / L hydrofluoric acid and 40g / L ethylene glycol, and use ultrasonic waves at room temperature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com