Preparation method of active supramolecular polymer based on layered double hydroxide bionic confinement driving

A technology of supramolecular polymers and hydroxides, which is applied in the direction of analyzing materials through chemical reactions, and can solve problems such as insufficient activation barriers to control growth kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

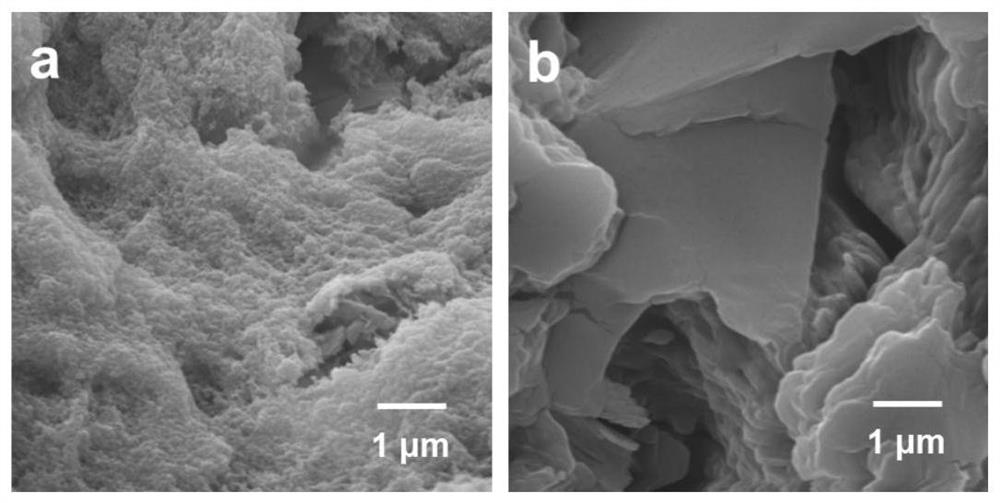

[0033] Step A: drop NaOH solution (0.500mol / L) into the solution containing 30.0mmol MgCl 2 ·6H 2 O and 10.0 mmol AlCl 3 9H 2 O in saline solution (50.0 mL) until pH ≈ 8.50, all solutions used were freshly prepared from decarbonated distilled water. The slurry was transferred to an autoclave and heated at 110°C for 24 hours, washed three times with decarbonated distilled water, dried in a vacuum oven at 70°C, and then used to obtain an LDH precursor with a size of 50 nm.

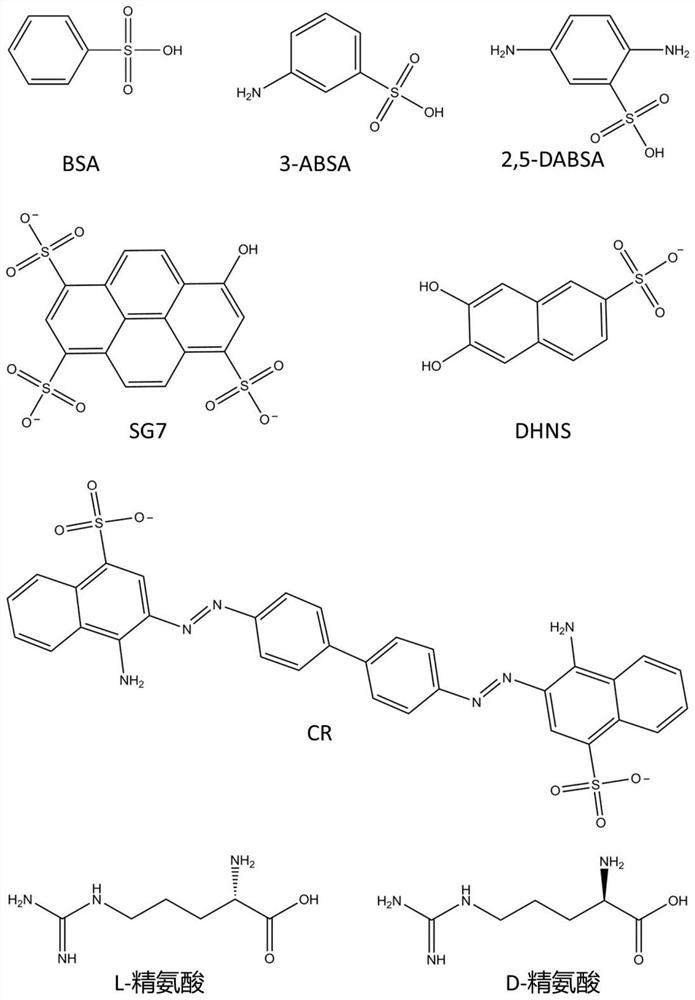

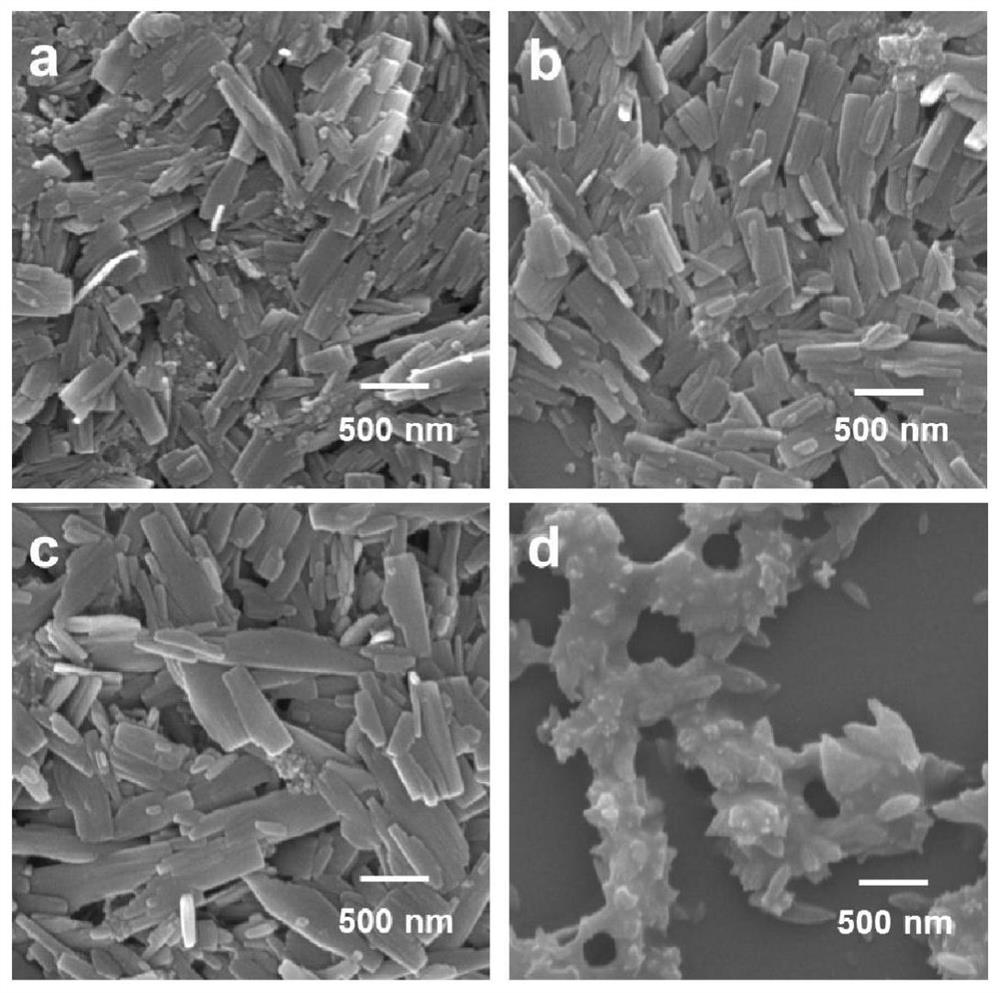

[0034]Step B: Use ion exchange to intercalate various small organic molecules into the interlayer of LDH. First prepare the stock solution (pH≈8.00, 12.5mmol / L) of small organic molecules (SG7, BSA, 3-ABSA, 2,5-DABSA, CR and DHNS) with decarbonated distilled water, and take 50mL stock solution respectively, Add 0.313g of LDH precursor powder to it while stirring, raise the temperature to 80°C, and 2 Ion exchanged under atmosphere for 24 hours, washed with carbon dioxide-free distilled water and anhydrou...

Embodiment 2

[0039] Step A: Preparation of LDHs of various sizes (all solutions were prepared with decarbonated distilled water and the LDH product was washed with decarbonated distilled water). 20nm LDH precursor: Add 50.0mL of NaCl solution (1.00mol / L) to a 500mL four-neck flask, add 50.0mL of 3.75mmol MgCl 2 ·6H 2 O and 1.25 mmol AlCl 3 9H 2 The salt solution of O is marked as solution A, and the 50.0mL NaOH solution (1.00mol / L) is marked as solution B, N 2 Add solutions A and B dropwise to the flask under atmosphere and stir vigorously. During the dropping process, maintain the pH of the suspension at ≈8.00. After the addition is complete, put the mixture under N 2 Aging at room temperature in the atmosphere for 24 hours, washing 3 times with distilled water to remove carbon dioxide, drying in a vacuum oven at 70°C and then ready for use; 50nm LDH precursor: see step A of Example 1 for the preparation method; 100nm LDH precursor: 50.0mL of NaCl solution (10.0mol / L) was added to a 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com