Garbage treatment equipment for river pollution treatment

A technology for waste treatment equipment and pollution control, which is applied in grain treatment, lighting and heating equipment, special-purpose ships, etc. It can solve the problems of existing risks and labor-intensive labor, so as to improve efficiency, reduce the risk of falling into the water, increase the Carrying capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

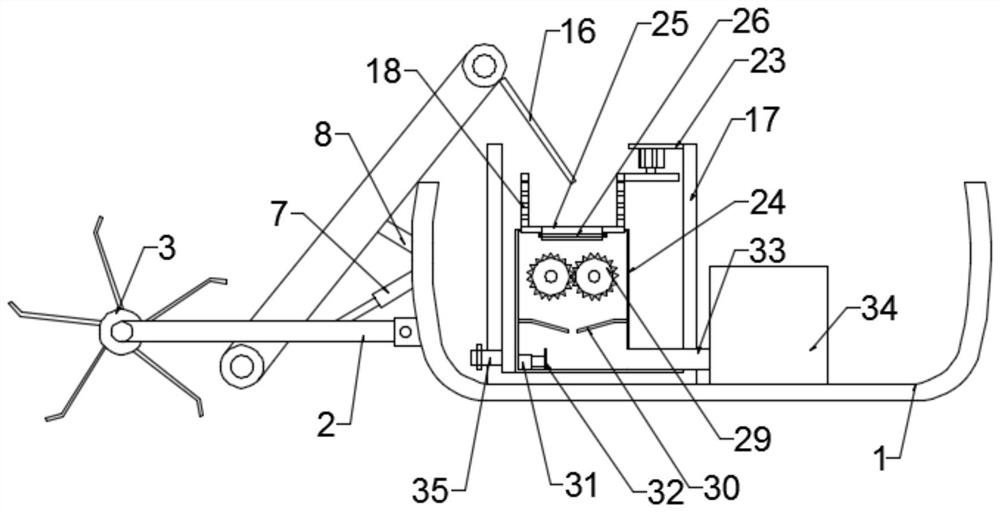

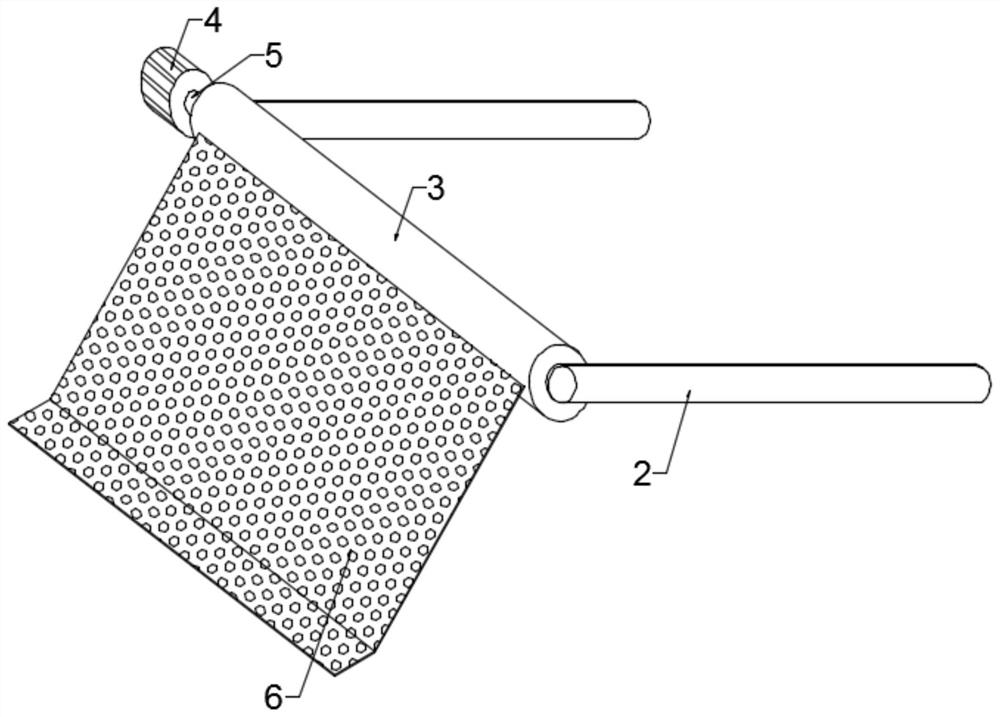

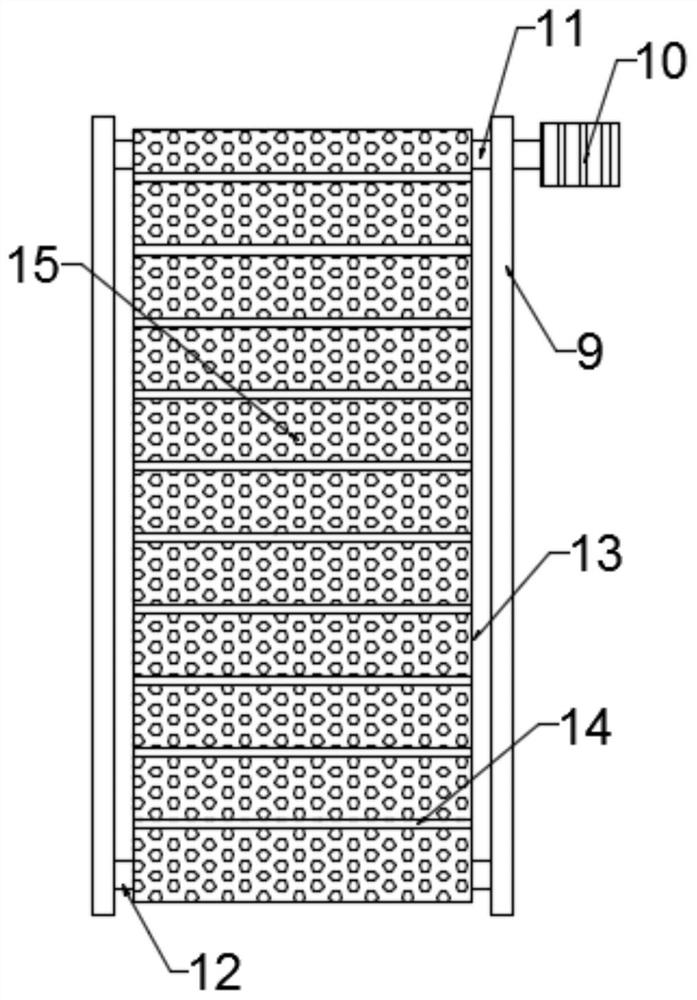

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a kind of garbage treatment equipment for river pollution control, the garbage treatment equipment includes a hull 1, one end of the hull 1 is equipped with a rotating salvage mechanism through two symmetrically arranged connecting rods 2, and the two A leakage transmission mechanism is installed between the two connecting rods 2, and the head end of the leakage transmission mechanism is located below the rotating salvage mechanism; the tail end of the leakage transmission mechanism is provided with a blanking plate 16, and the blanking plate 16 Located on the upper end of the garbage disposal box 17; the inside of the garbage disposal box 17 is equipped with a water-spinning mechanism, and the water-spinning mechanism is installed on the top of the inner cylinder 24 through a rotating assembly, and the side wall of the garbage disposal box 17 is provided with Sewage outlet 35 ; inside the inner...

Embodiment 2

[0047] Such as Figure 5 As shown, in another embodiment provided by the present invention, the rotating assembly includes a chute 27, the chute 27 is set on the side wall of the top opening of the inner cylinder 24, and the bottom of the water spinner 18 is fixed with An annular slider 28 is rotatably installed in the slide groove 27 .

[0048] Installing the water-spinning tube 18 on the top of the inner tube 24 improves the stability of the water-spinning tube 18 when rotating, and the cooperation of the annular slider 28 and the chute 27 ensures that the water-spinning tube 18 can move smoothly in the inner tube 24 turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com