Anti-winding mechanism for intelligent sewage pump

An anti-entanglement and sewage technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, can solve the problems of the impeller entanglement, etc., and achieve the effect of prolonging the life and improving the filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

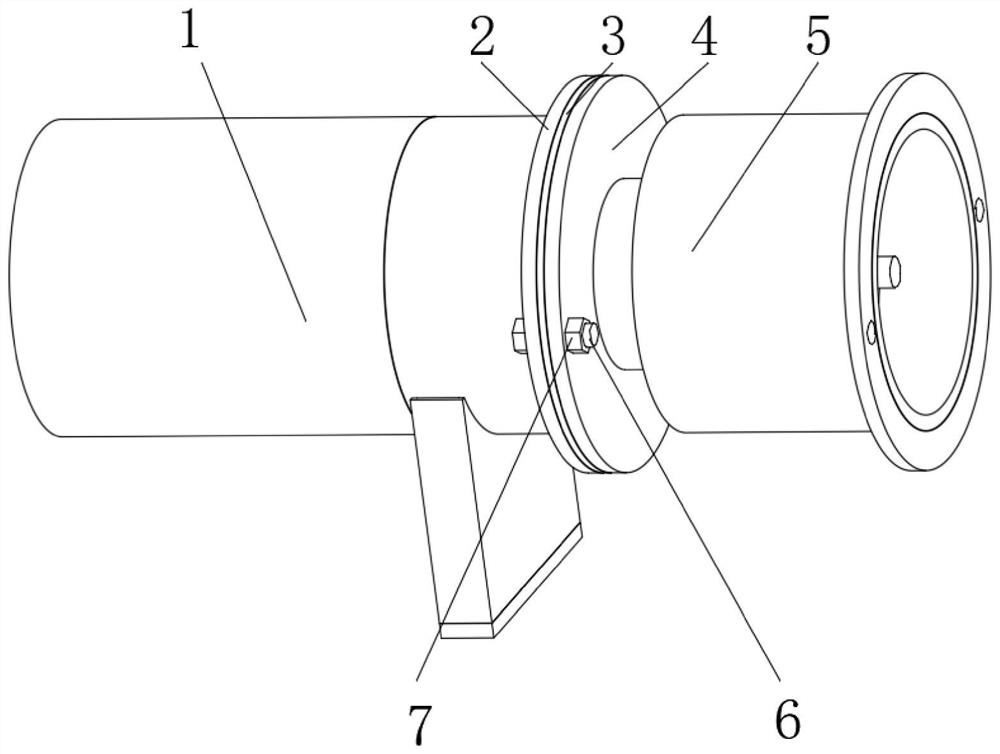

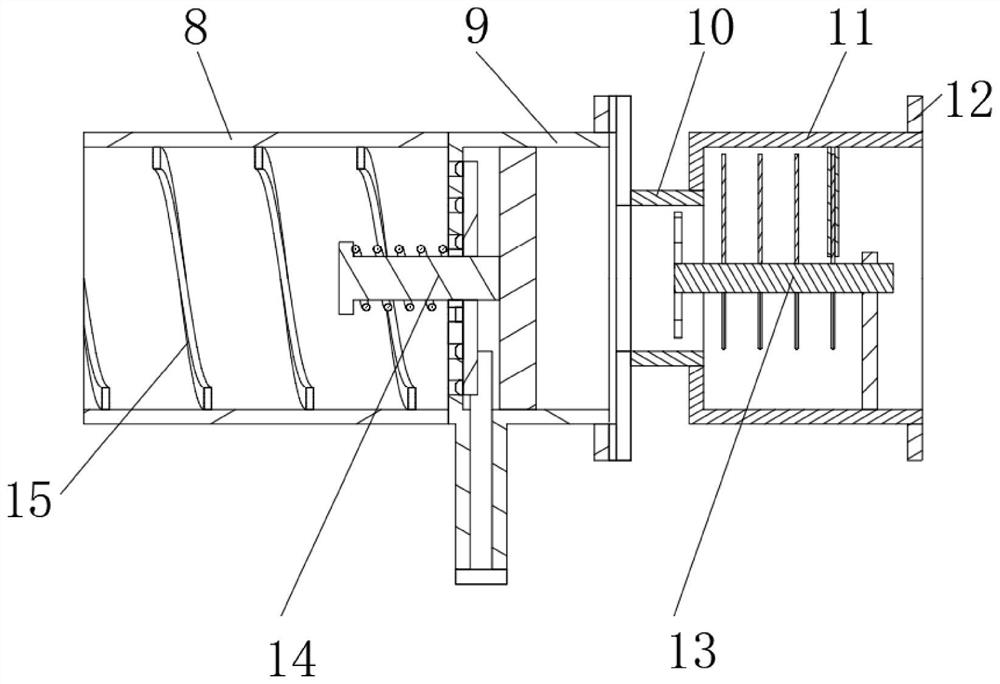

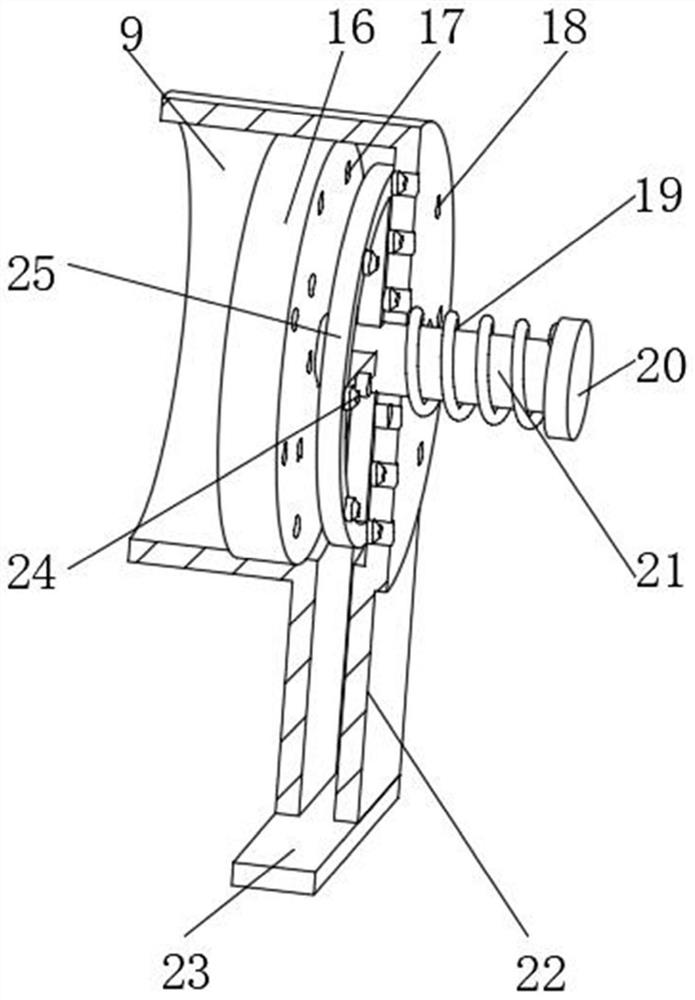

[0033] An anti-winding mechanism for an intelligent sewage pump, such as figure 1 , 2 , 3, including a filter part 1, the filter part 1 is welded by the swirl tube 8 and the filter tube 9 using laser seamless welding technology, the inside of the filter tube 9 is provided with a filter assembly 14, the filter Component 14 comprises filter plate 16 and sealing frame 25, and described filter plate 16 and sealing frame 25 axial place inwalls are welded with same slide bar 21, and slide bar 21 is slidably connected on the inwall of filter tube 9, and the other of slide bar 21 One side outer wall is fixed with limiting plate 20 by bolt, and the outer wall of slide bar 21 is sheathed with spring 19, and one side inner wall of filter tube 9 is provided with uniform permeable hole 2 18, and the outer wall of sealing frame 25 is integrally formed with permeable hole 2 The sealing protrusion 24 corresponding to the position 18, the inner wall of the filter plate 16 is provided with the...

Embodiment 2

[0036] An anti-winding mechanism for an intelligent sewage pump, such as figure 2 As shown, in order to solve the problem of flow direction; this embodiment makes the following improvements on the basis of embodiment 1: the inner wall of the swirl tube 8 is fixed with a helical blade 15 .

[0037] When this embodiment is in use, when the water flow enters, the fibrous dirt is almost parallel to the direction of the water flow, that is, the axial direction of the pipeline, so it is easy to enter from the second permeable hole 18, and the device is provided with a helical blade 15, so that the water flow from When flowing in the swirl tube 8, it will form a swirl shape to ensure that the fibrous dirt can be preliminarily filtered by the side wall of the filter tube 9, further improving its filtering effect and preventing the dirt from entering the sewage pump.

Embodiment 3

[0039] An anti-winding mechanism for an intelligent sewage pump, such as figure 1 , 4 , 5, in order to further solve the winding problem; this embodiment makes the following improvements on the basis of embodiment 2: the outer wall of one side of the filter part 1 is welded with a flange-2, and the outer wall of one side of the flange-2 passes through The connecting bolt 6 is connected with the flange 2 4, and the outer wall of the connecting bolt 6 is connected with the fastening nut 7 through threads, and a gasket 3 is arranged between the flange 1 2 and the flange 2 4, and the outer wall of one side of the flange 2 4 is welded There is a cutting part 5, the cutting part 5 is welded by the power pipe 10 and the cutting pipe 11 by seamless laser welding technology, the diameter of the power pipe 10 is smaller than the diameter of the cutting pipe 11, and one side of the cutting pipe 11 The outer wall is welded with a flange three 12, and the inner wall of the cutting pipe 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com