Environment-friendly recycling full-automatic disassembling machine for scrapped power batteries and process method thereof

A fully automatic technology for power batteries, applied in the field of fully automatic dismantling machines for environmentally friendly recycling of scrapped power batteries, which can solve problems such as high cost, long separation process of mixed materials, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

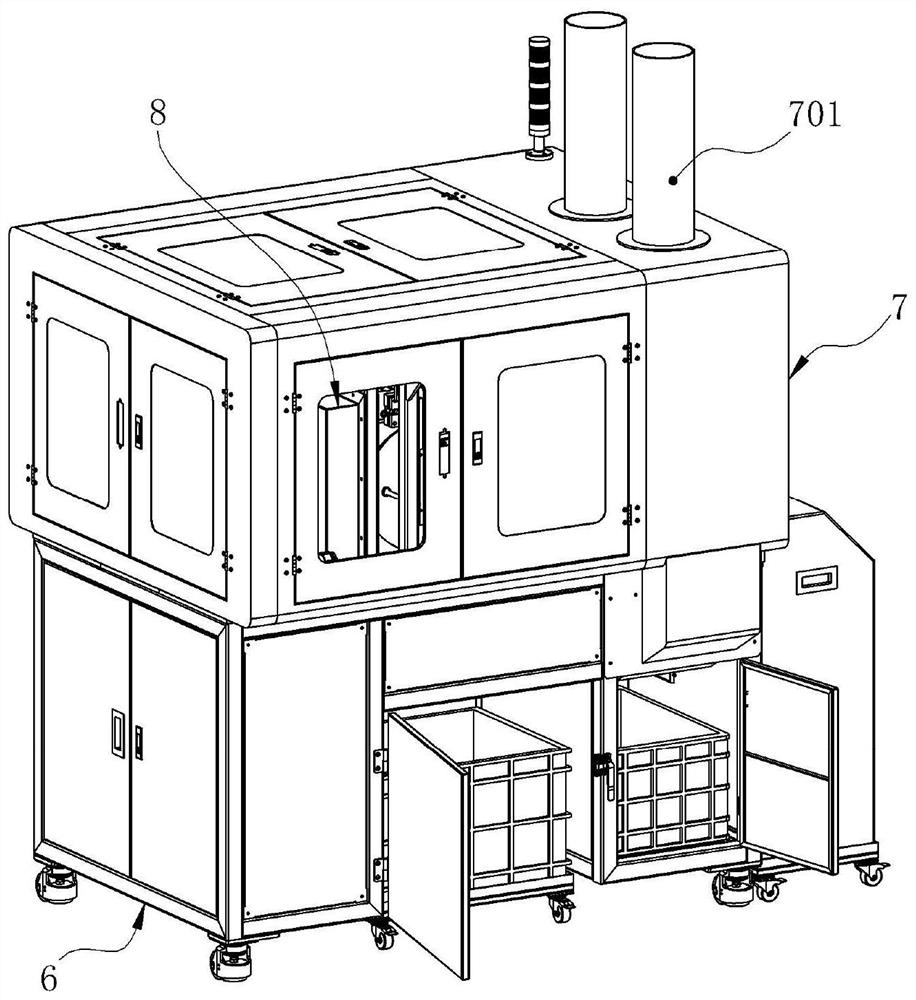

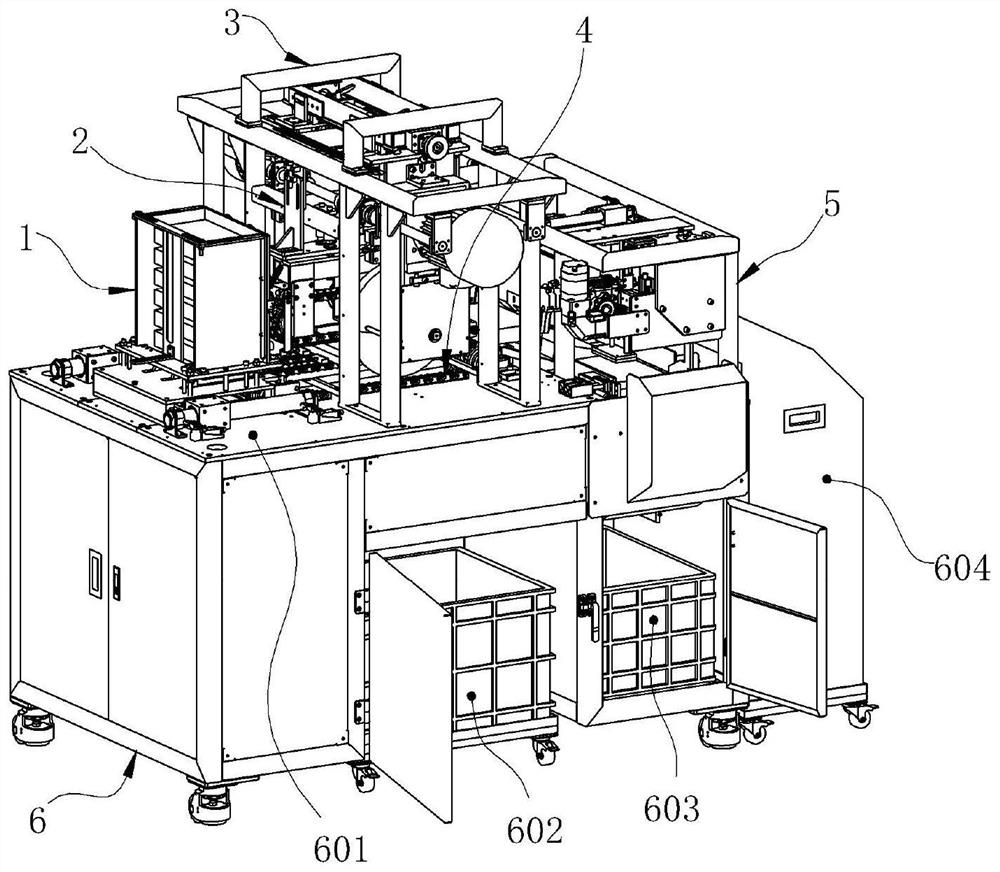

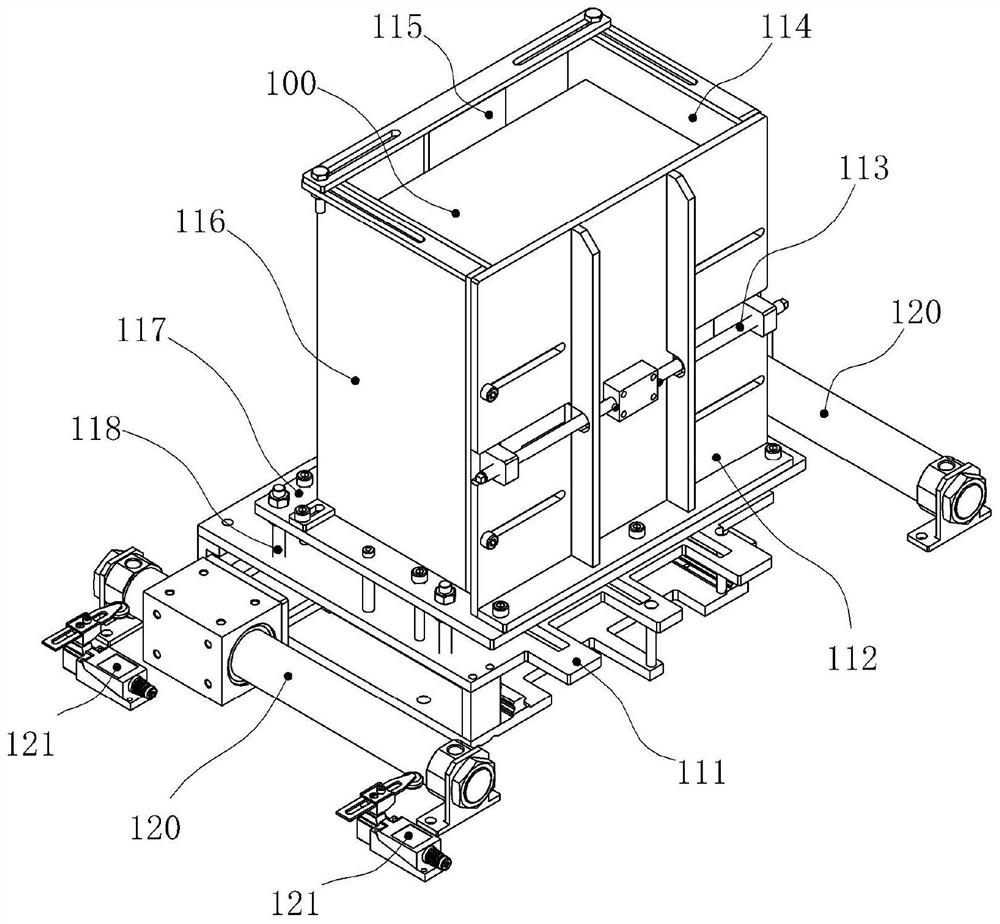

[0077] Such as figure 1 and figure 2 As shown, this embodiment is a fully automatic dismantling machine for environmentally friendly recycling of scrapped power batteries, which is used for fully automatic dismantling of scrapped power batteries to separate the battery shell and battery core materials, including a silo device 1, a pressing device 2, and a cutting device 3. Conveying device 4, coring device 5, frame platform 6, outer protective cover device 7, inner protective cover device 8. Through the dismantling machine of this embodiment, the dust exhaust gas and noise can be effectively sealed and isolated to prevent the battery dismantling dust exhaust gas from leaking and polluting the environment, and the fully automatic production of power battery feeding, transportation, cutting, and coring can be realized, and the production efficiency and resource recovery rate can be significantly improved. .

[0078] The bin device 1, the cutting device 3, the conveying device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com