Preparation method of super-hydrophilic ceramic membrane

A super-hydrophilic, ceramic membrane technology, applied in the field of ceramic membrane materials, can solve the problems of insufficient hydrophilicity, membrane pollution, etc., and achieve the effect of improving hydrophilicity, improving stability, and avoiding the reduction of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Pretreatment of Ceramic Membrane Elements

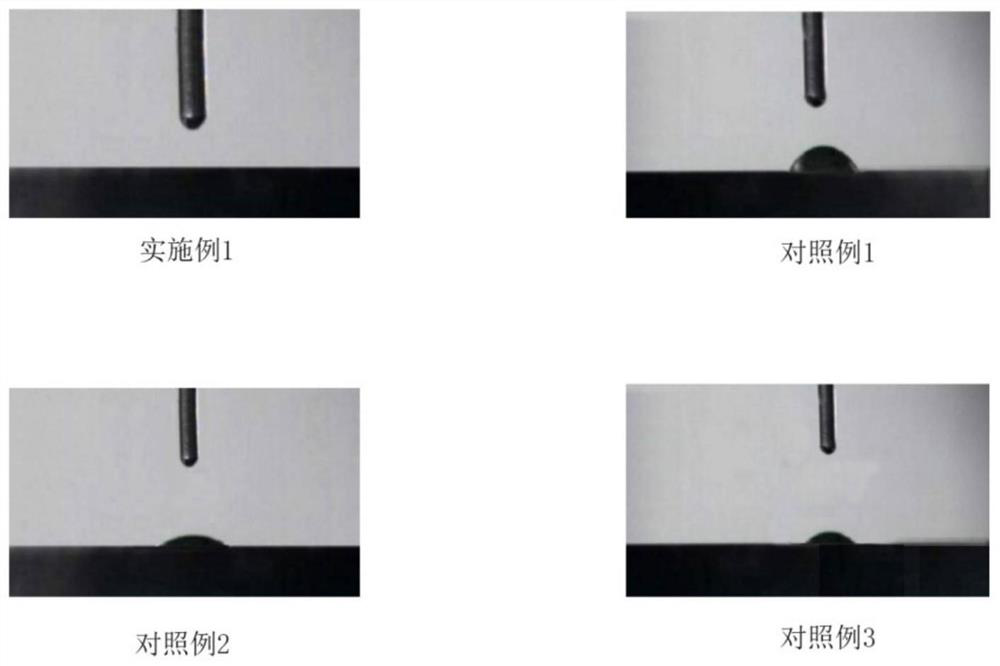

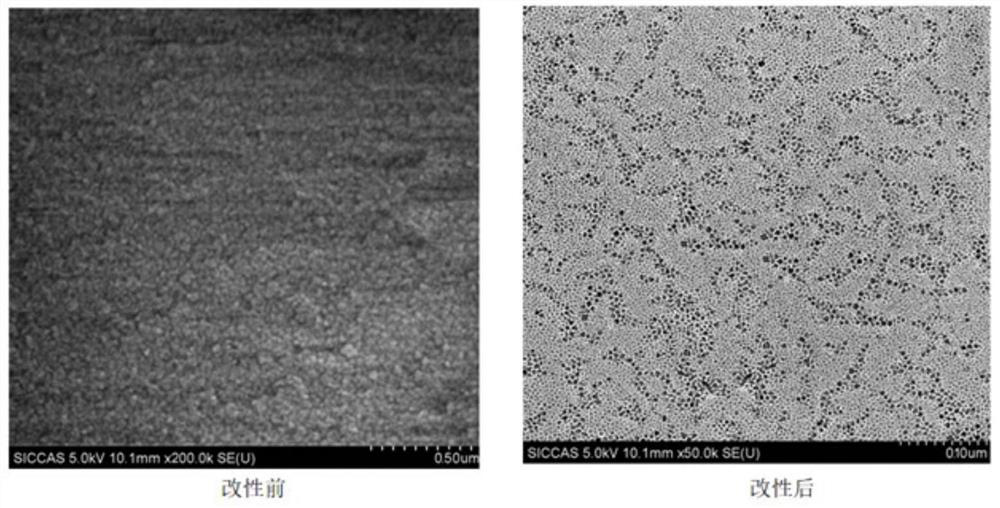

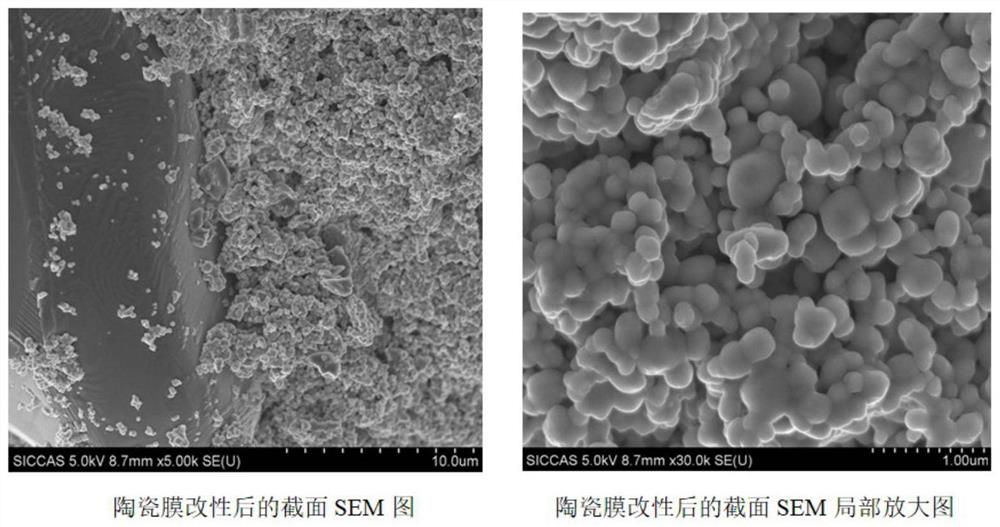

[0050] The aluminum oxide ceramic membrane with an outer diameter of 30mm and a channel number of 19, a length of 1016mm and a pore diameter of 200nm is selected as the modified membrane element. The contact angle was measured with water as the medium before modification. 5% sulfuric acid solution and 30% hydrogen peroxide solution are mixed according to the volume ratio of 7:3 to form a treatment solution, and the ceramic membrane to be modified is treated by cross-flow filtration at room temperature for 15 hours. Then rinse the ceramic membrane with deionized water to neutral. Then the pretreated ceramic membrane was dried at 120 °C for 2 h. spare.

[0051] Carboxylation Modification of Ceramic Membrane Elements

[0052] Dissolve cysteine powder in 10% acetic acid aqueous solution to form a 5% modifier solution. The above modifier solution was circulated through the pretreated ceramic membrane by means of cross-flow f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com