Polyurethane material and polyurethane foam

A polyurethane material and polyurethane foam technology, applied in the field of polyurethane materials, can solve problems such as poor dimensional stability, low initial strength, and affect assembly, and achieve the effects of good dimensional stability, high initial hardness, and reduced odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

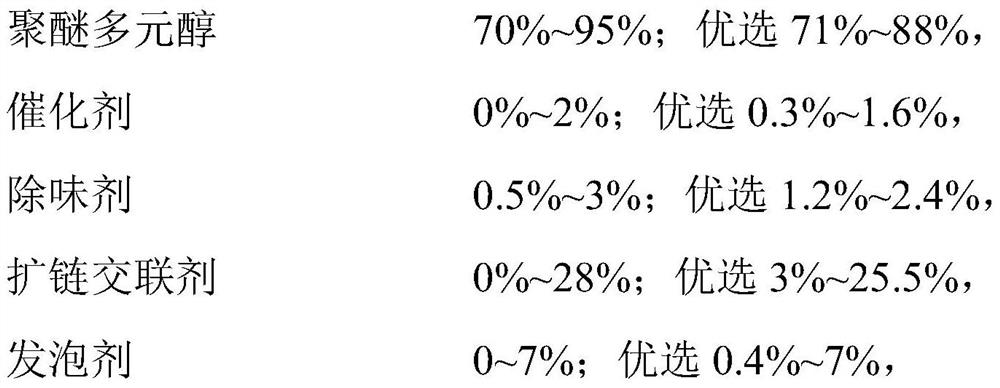

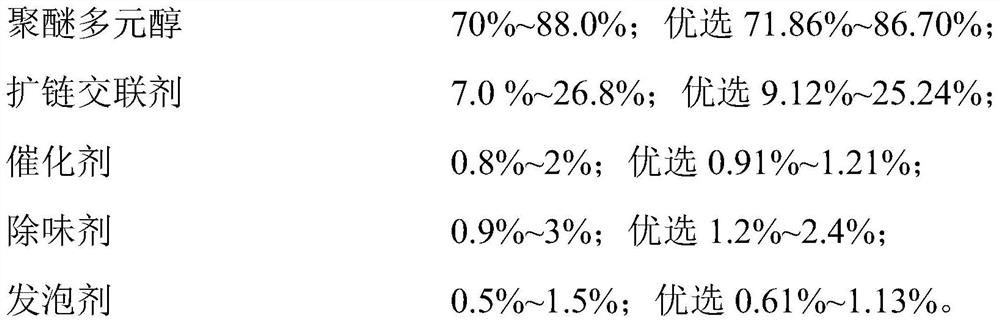

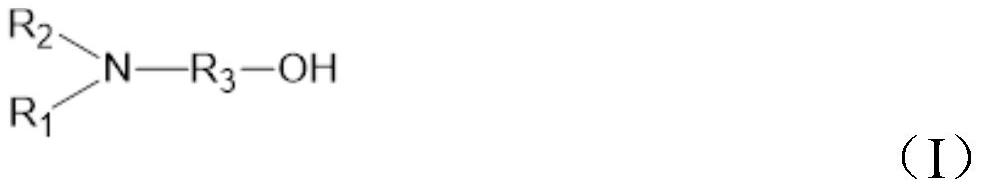

Method used

Image

Examples

Embodiment 1-3、 comparative example 1-3

[0086] Preparation method of component A: add each component according to the corresponding parts by mass and stir and mix evenly to obtain the corresponding component A.

[0087] Odor test of polyurethane foam: mix component A and component B evenly in an open container, and obtain the corresponding polyurethane foam after it is completely foamed and cured, cut the polyurethane foam into 1-2cm cubes, and cut 45g of Put the foam cubes into a standard glass scent bottle and tighten the cap; place the scent bottle in an oven at 80°C for 2 hours, take it out, and open the bottle cap to smell. The test method refers to PV3900

[0088] Table 1 Example 1-3, comparative example 1-3 each component addition amount and performance (addition amount is mass parts)

[0089]

Embodiment 4-10、 comparative example 4

[0090] Examples 4-10, Comparative Example 4: Polyurethane foams were prepared according to the formula shown in Table 2, and the addition amounts of each component were parts by mass.

[0091] The performance test result of table 2 embodiment formula

[0092]

[0093]Initial hardness test: Control the temperature of component A and component B to 25°C, mix and stir evenly according to the corresponding proportion, then pour the mixture into a mold with an actual mold temperature of 60-65°C, close the mold and hold the pressure for 4 minutes ; Immediately after opening the mold, use a hardness tester to test the hardness of the foam in the mold. Hardness test standard refers to GB / T531.1-2008.

[0094] A component viscosity test standard refers to GB / T12008.7-2010.

[0095] As can be seen from Table 1 and Table 2, the odor of the polyurethane material prepared by the deodorant of the present invention is significantly reduced, and the polyurethane foam prepared by the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com