Bright-color super-weatherability exterior wall latex paint and preparation method thereof

A super-weather-resistant and exterior wall technology, applied in latex paint, coating, etc., can solve the problems of super-weather-resistant acrylic latex paint not bright enough, paint film is not durable enough, etc., to achieve outstanding adhesion and waterproof, excellent water resistance, The effect of excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

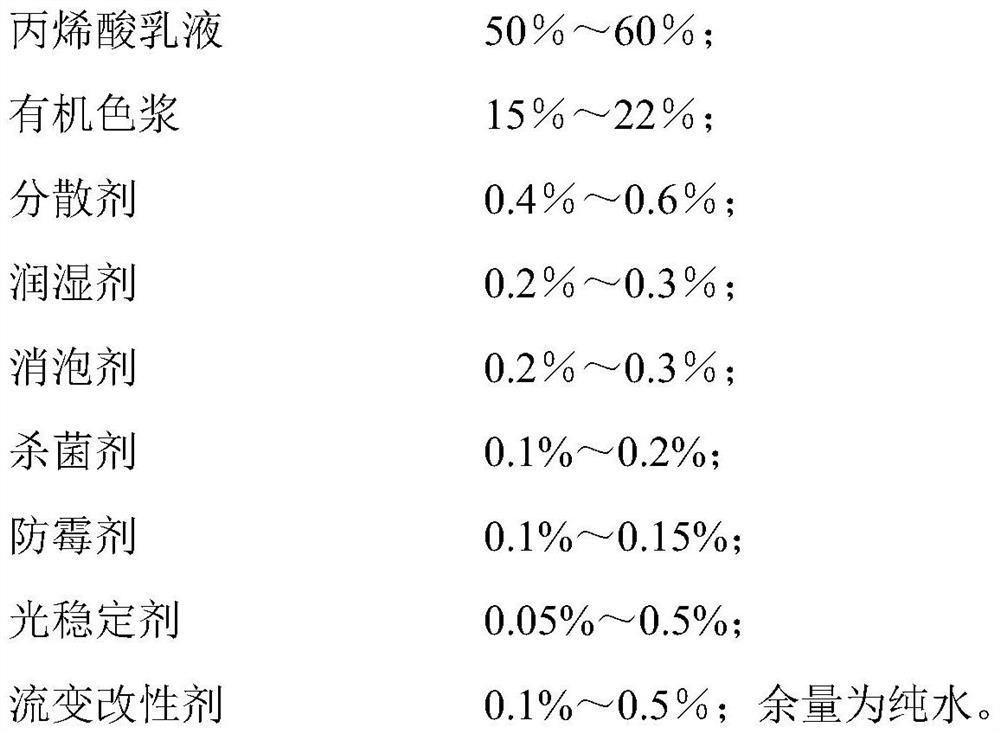

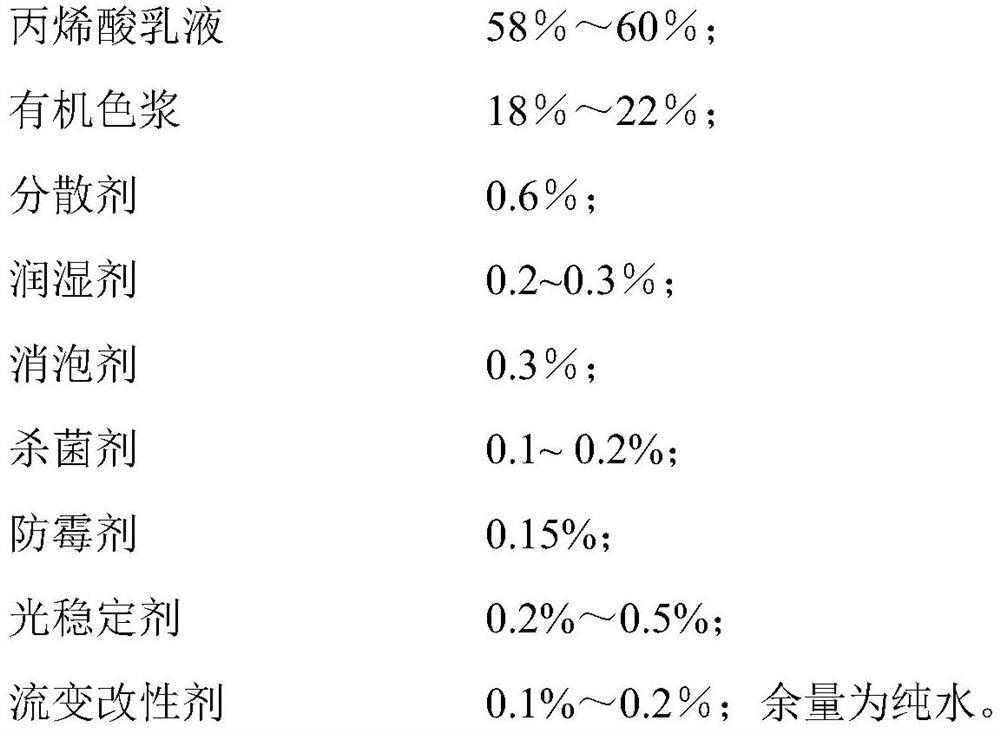

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 (comparative example)

[0045] The preparation steps of product of the present invention (below all are percentage by weight):

[0046] (1) Add 25% pure water in the reactor;

[0047] (2) Add 55% acrylic acid emulsion into the reaction kettle, and stir for 3 minutes at 600-800 rpms;

[0048](3) Stir and add 0.6% dispersant, 0.3% wetting agent and 0.2% defoamer at a rotating speed of 600-800rpms, and continue to stir and disperse for 5 minutes;

[0049] (4) Stir and add 10% organic color paste at a speed of 600-800 rpms, adjust the speed to 1000-1200 rpms, and stir for another 10 minutes;

[0050] (5) Reactor temperature ≤ 50°C, stirring and adding 0.2% fungicide, 0.15% antifungal agent and 0.1% defoamer at 600-800rpms, stirring for 5 minutes;

[0051] (6) Adjust the rotating speed to 1000-1200rpms, add 0.5% rheology modifier and stir for 5 minutes under stirring state;

[0052] (7) Add 7.95% pure water and stir well to get the finished product.

Embodiment 2

[0054] The preparation steps of product of the present invention (below all are percentage by weight):

[0055] (1) Add 25% pure water in the reactor;

[0056] (2) Add 50% acrylic acid emulsion into the reaction kettle, and stir for 3 minutes at 600-800 rpms;

[0057] (3) Stir and add 0.5% dispersant, 0.25% wetting agent and 0.2% defoamer at 600-800rpms, stir and disperse for 5 minutes;

[0058] (4) Stir and add 15% organic color paste at 600-800 rpms, and continue stirring for 10 minutes;

[0059] (5) Reactor temperature ≤ 50°C, add 0.1% bactericide, 0.15% antifungal agent and 0.1% defoamer at 600-800rpms and stir for 5 minutes;

[0060] (6) Adjust the rotating speed to 1000-1200rpms, add 0.05% light stabilizer and stir for 3 minutes under stirring state;

[0061] (7) Adjust the rotating speed to 600-800rpms, add 0.4% rheology modifier and stir for 5 minutes under stirring state;

[0062] (8) Add 8.25% pure water and stir well to get the finished product.

Embodiment 3

[0064] The preparation steps of product of the present invention (below all are percentage by weight):

[0065] (1) Add 25% pure water in the reactor;

[0066] (2) Add 55% acrylic acid emulsion into the reaction kettle, and stir for 3 minutes at 600-800 rpms;

[0067] (3) Stir and add 0.4% dispersant, 0.3% wetting agent and 0.13% defoamer at 600-800rpms, stir and disperse for 5 minutes;

[0068] (4) Stir and add 18% organic color paste at a rotating speed of 600-800 rpms, and continue stirring for 10 minutes;

[0069] (5) Reactor temperature ≤ 50°C, add 0.2% fungicide, 0.1% antifungal agent and 0.07% defoamer at 600-800rpms and stir for 5 minutes;

[0070] (6) Adjust the rotating speed to 1000-1200rpms, add 0.1% light stabilizer and stir for 3 minutes under stirring state;

[0071] (7) Adjust the rotating speed to 600-800rpms, add 0.3% rheology modifier under stirring state and stir for 5 minutes;

[0072] (8) Add 0.4% pure water and stir well to get the finished product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com