One-way negative pressure adsorption sampling and filtering device and method

A filtration device and negative pressure technology, applied in the field of biological and chemical filtration and sample preparation, can solve the problems of long sampling and transfer operations, increase the risk of cross-contamination, and prolong the inspection time period, so as to prevent the safety risks of biochemical operations and improve inspection. Aging and work efficiency, the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

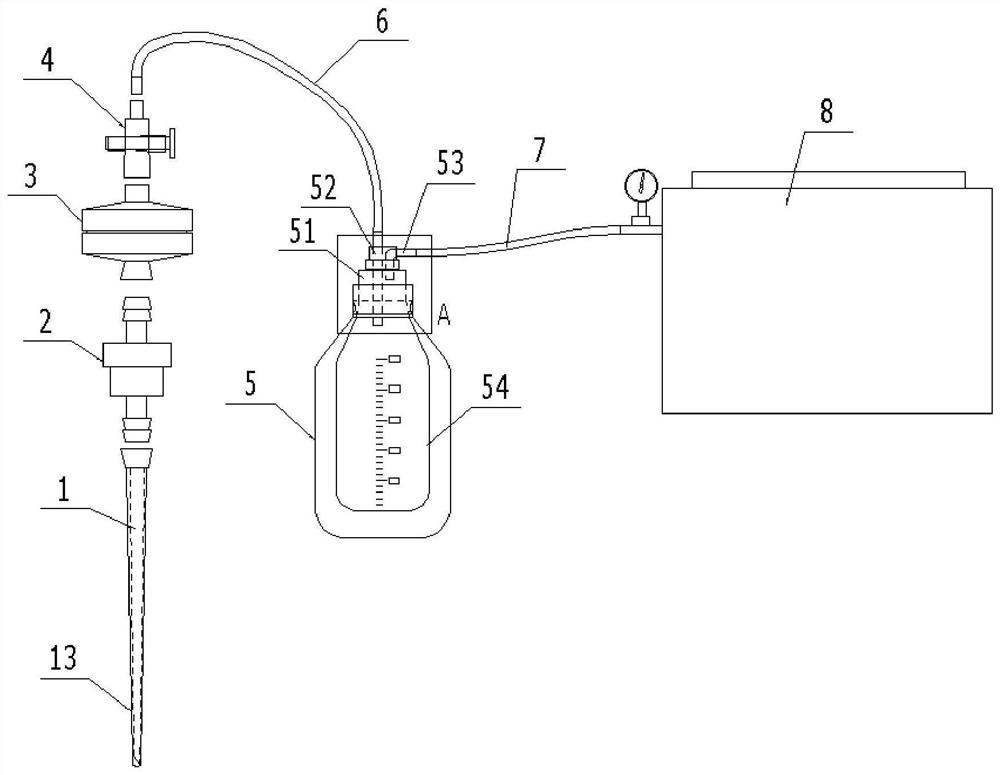

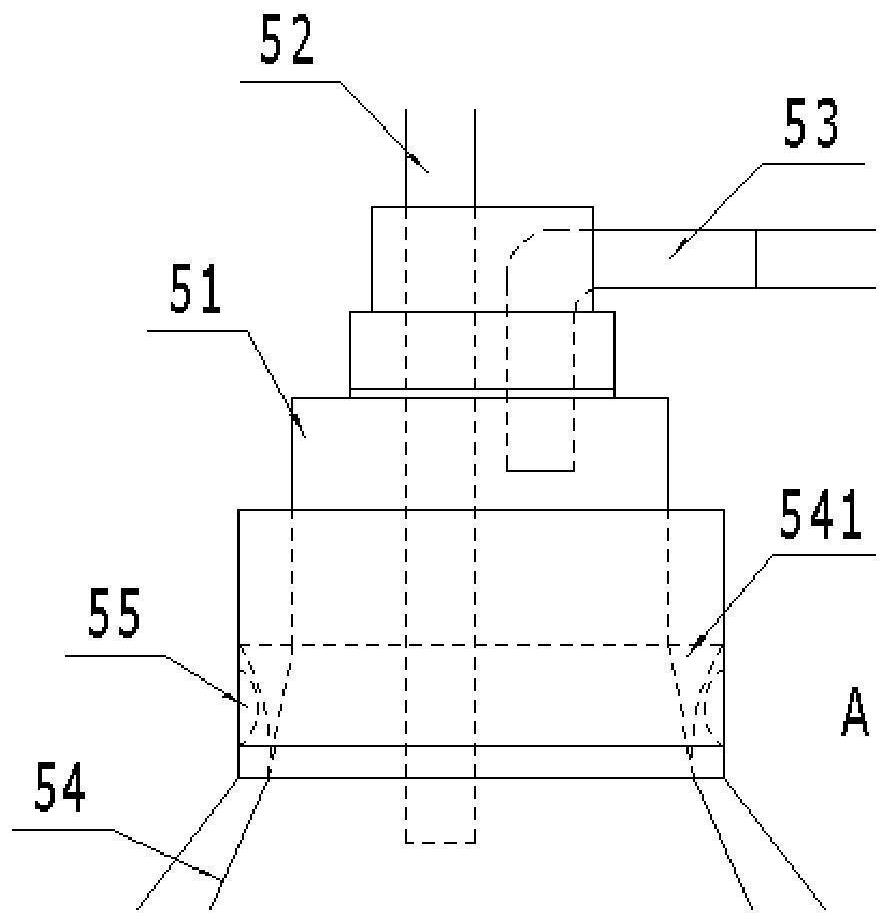

[0058] see figure 1 , is a schematic structural diagram of a one-way negative pressure adsorption sampling filter device provided by an embodiment of the present invention. The device is mainly used in laboratory biochemical filtration and liquid extraction operations. The device comprises a liquid-taking pipe 1, a filter 3 and a negative pressure measuring bottle 5.

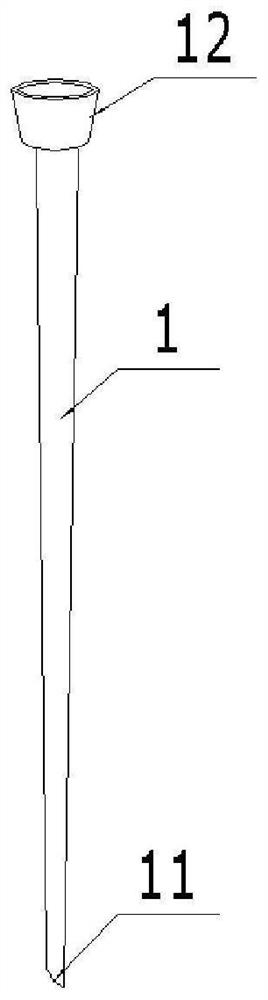

[0059] see Figure 1 to Figure 3 The liquid inlet end of the liquid taking pipe 1 is provided with an oblique puncture port 11 , and the liquid outlet end is connected with a one-way valve 2 . The liquid suction operation is performed through the liquid pipe, and the functions of one-way cut-off and reverse liquid extraction are realized.

[0060] Wherein, the tube head of the liquid-taking tube 1 can be made of different corrosion-resistant materials and tube diameter specifications. For example, the material of the head of the liquid-taking pipe is suitable for the liquid, and the length of the liquid-taki...

Embodiment 2

[0086] see Figure 9 , is a structural schematic diagram of a one-way negative pressure adsorption sampling filter device provided in another embodiment of the present invention, the device includes a liquid-taking tube 1 , a filter 3 and a negative pressure measuring bottle 5 . The structure of this device is basically the same as that of Embodiment 1, the difference is that

[0087] The negative pressure metering bottle 5 includes a liquid inlet opening and a negative pressure exhaust port, the liquid inlet opening is arranged on the bottom of the negative pressure metering bottle 5, and the negative pressure exhaust port is arranged on the side wall of the top of the negative pressure metering bottle 5. The liquid opening is connected to the shut-off valve 4 through the connecting pipe 6, and the negative pressure exhaust port is connected to the negative pressure vacuum pump 8 through the air guide tube 7, so that a negative pressure environment can be formed for the devic...

Embodiment 3

[0090] see figure 1 , another embodiment of the present invention provides a one-way negative pressure adsorption sampling filter device, the structure of the device is basically the same as that of Example 1, the difference is that

[0091] The device is mainly used for aseptic preparation of microbial samples. Wherein, the liquid-taking tube 1 is a minimally invasive puncture tube; the tube head of the liquid-taking tube 1 is covered with a tube head sterile protective cover 13; it is used to realize aseptic protection for the tube head of the liquid-taking tube. The length of the liquid-taking pipe 1 is 15-20 cm.

[0092] A protective film 33 is provided on the side of the filter chamber 31 close to the liquid outlet, and the filter medium 32 is a microporous filter film for absorbing microbial samples. Wherein, the microporous filter membrane 32 is a 0.45 μm filter membrane.

[0093] In this embodiment, a microporous filter membrane and a protective film 33 are sequenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com