Method for testing volume expansion coefficient of irregular or micro-scale crystal material

A technology of volume expansion coefficient and crystal materials, which is applied to the analysis of materials, material analysis using radiation diffraction, material analysis using wave/particle radiation, etc., can solve the problems of limited test objects and difficult realization of micro-scale material samples, etc. Achieve low sample requirements, solve the problem of difficult detection of expansion coefficient and strong application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] For solder joint materials, the coefficient of thermal expansion is used as the basic data for thermal stress and strain analysis, simulation, and structural design. When the expansion coefficients of the packaging materials are different, especially when the expansion coefficients differ greatly (Δα>5×10 -6 ℃ -1 ), the temperature alternation will cause the package as a whole to be subjected to severe thermal stress shocks. When the strength of the package solder joints is low, the continuous thermal stress shock will cause cracks in the solder joints, resulting in thermal mismatch problems. For example, the fatigue damage caused by the thermal expansion coefficient mismatch between the solder and the pin material will lead to local cracking of the pin solder; Overall expansion mismatch. In this part, Sn metal solder (Sn [wt%] above 98.6%) is selected for thermal expansion coefficient test and analysis.

[0091] 1) X-ray diffraction spectrum collection

[0092]Use...

Embodiment 2

[0104] PbSn solder is still the most reliable soldering material and is widely used in aerospace, ships, weapons and other fields. As mentioned above, its welding reliability largely depends on the matching of thermal expansion coefficient. PbSn solder balls (specification: micro-scale, diameter 250 μm. Composition: Pb [wt%] = 36.8%, Sn [wt%] = 63.2%) were selected for thermal expansion coefficient test and analysis. To exemplify materials in various phases.

[0105] 1) X-ray diffraction spectrum collection

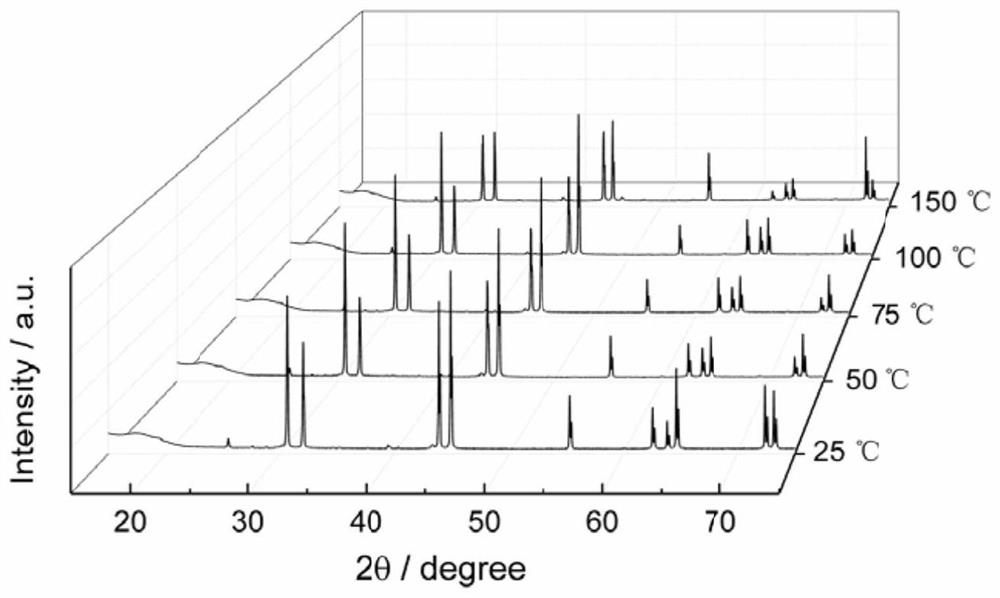

[0106] Use X-ray diffractometer to collect diffraction spectra at different temperatures, tube voltage: 40kV, tube current: 30mA, Cu K α Radiation, scan step size and speed were set to 0.02° and 0.5° / min, respectively. The test temperature settings include: 25°C, 50°C, 75°C, and 100°C. The XRD patterns obtained at different temperatures are as follows: Figure 4 shown.

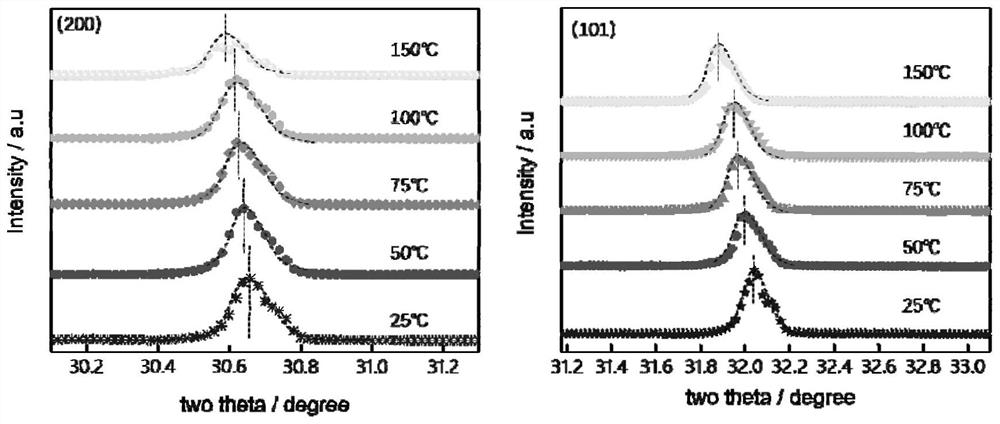

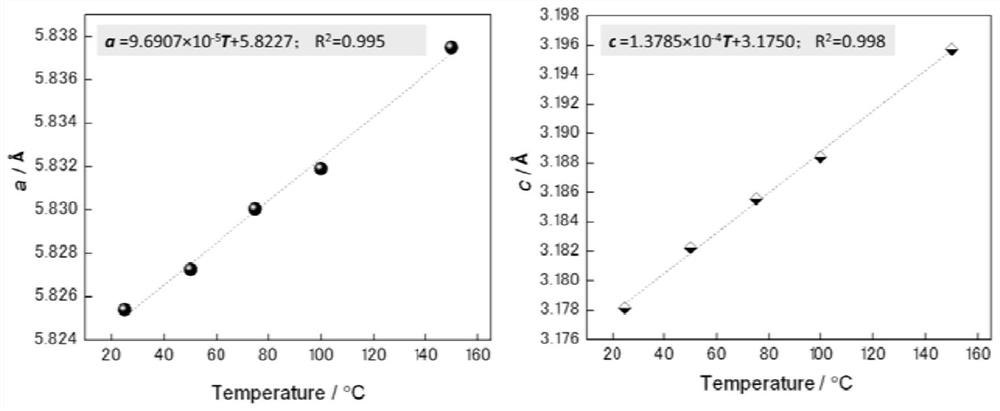

[0107] 2) Calculation of lattice constant

[0108] Analysis of the XRD spectrum shows that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com